Polycarbonate composition with high ball pressure temperature and solvent resistance, and preparation method thereof

A polycarbonate and solvent resistance technology, applied in the field of polycarbonate compositions and their preparation, can solve the problems of surface cracks, unfavorable material coloring, and inability to fundamentally eliminate cracking, etc., so as to improve toughness and solvent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

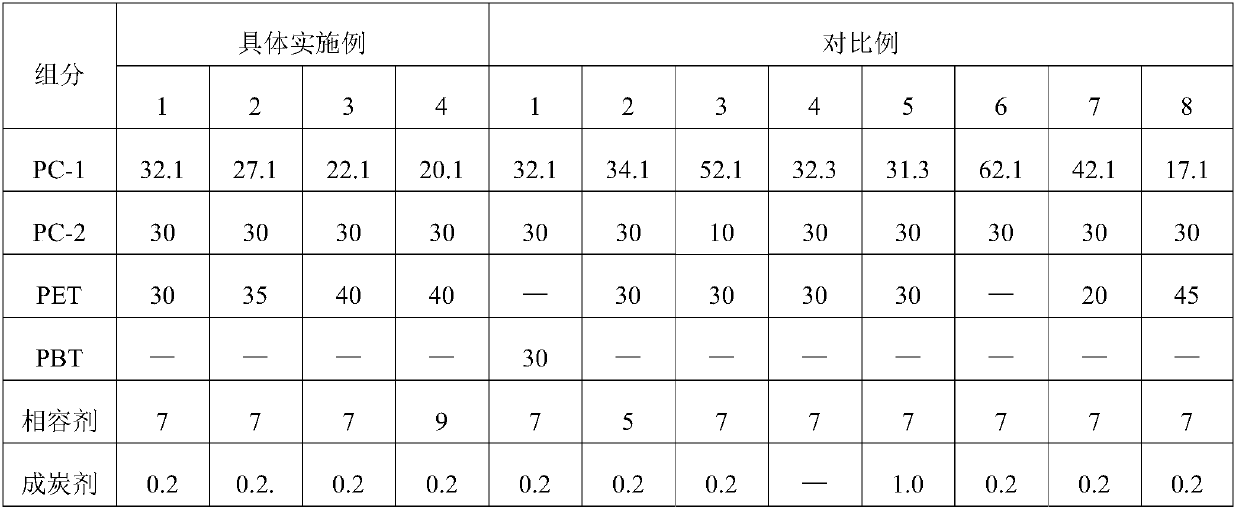

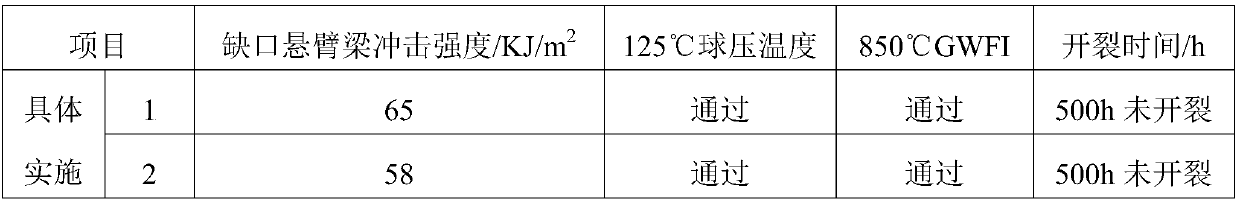

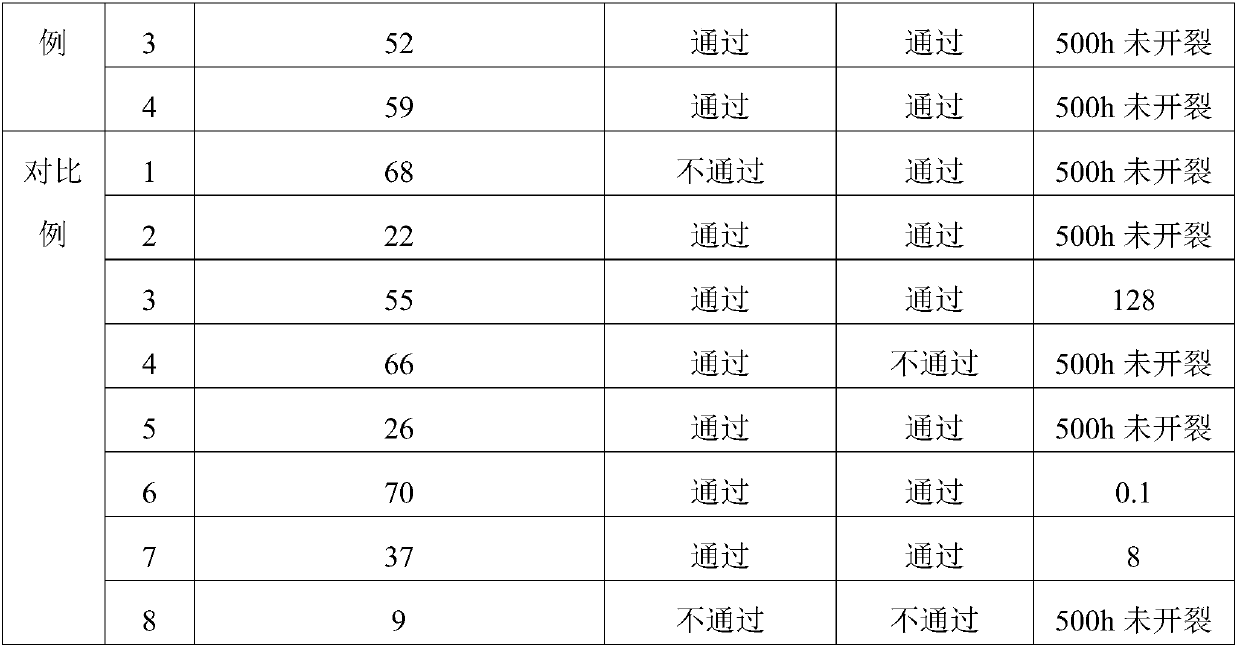

[0016] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific embodiments of the present invention will be further described in detail below in conjunction with specific examples. The following examples are used to illustrate the present invention, but not to limit it scope of the invention.

[0017] The raw materials adopted in following specific examples and comparative examples are as follows:

[0018] PC-1: The viscosity average molecular weight is 22000, the brand is S-2000F, and the manufacturer is Mitsubishi;

[0019] PC-2: The viscosity-average molecular weight is 28000, the brand is E-1000F, and the manufacturer is Mitsubishi;

[0020] PBT resin: the intrinsic viscosity is 1.05dl / g, the brand is GX121, and the manufacturer is Yizheng Petrochemical;

[0021] PET resin: the intrinsic viscosity is 0.85dl / g, the grade is PET SB500, and the manufacturer is Yiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com