Liquid crystal composition for optical switching element, mixture, polymer/liquid crystal composite material, element and lidar

A liquid crystal composition and light conversion technology, applied in liquid crystal materials, optics, nonlinear optics, etc., can solve the problems of limited control times and long response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

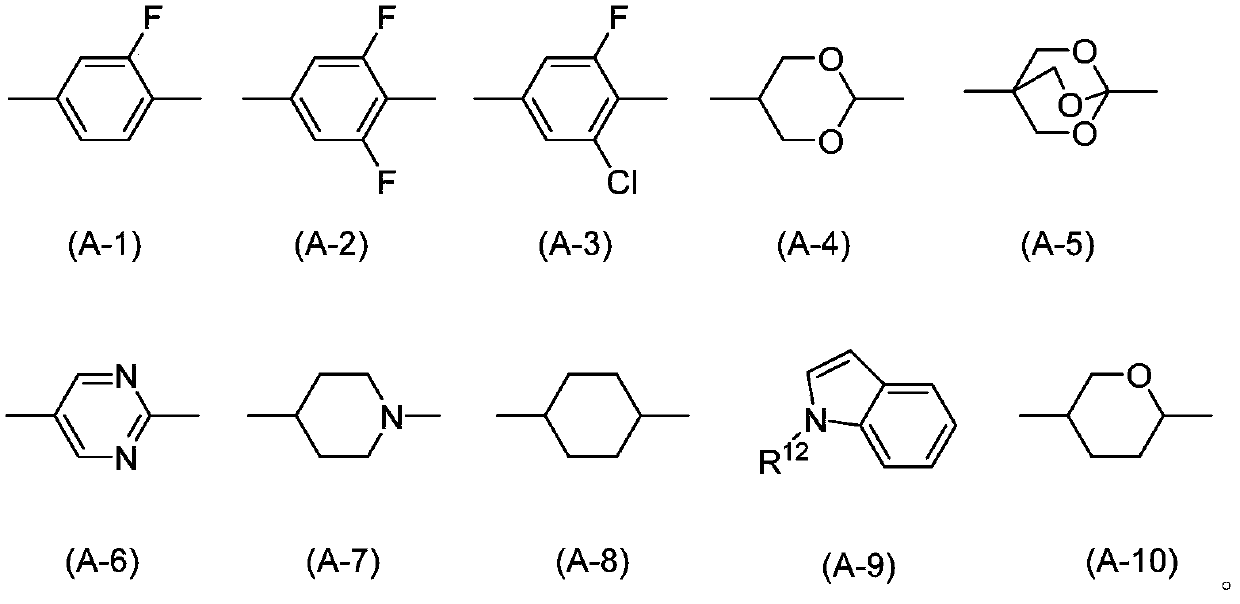

[0466] A nematic liquid crystal composition NLC-A was prepared by mixing the liquid crystal compounds shown in the figure below in the following ratios.

[0467] Nematic liquid crystal composition NLC-A

[0468]

[0469]

[0470] The phase transition temperature (° C.) of the nematic liquid crystal composition NLC-A is N 87.8I.

[0471] Next, a chiral nematic liquid crystal composition CLC-A1 comprising a nematic liquid crystal composition NLC-A (95.2% by weight) and a chiral agent (8H) BN-H5 (4.8% by weight) was obtained.

[0472] The phase transition temperature (℃) of the chiral nematic liquid crystal composition CLC-A1 is N * 79.0BP-I.

[0473] Preparation of the mixture (MLC-A1) of polymerizable monomer and chiral nematic liquid crystal composition

[0474] As a mixture of chiral nematic liquid crystal composition and polymerizable monomer, 88.8% by weight of chiral nematic liquid crystal composition CLC-A1, 6.0% by weight of n-hexadecyl acrylate, and 4.8% by weigh...

Embodiment 2

[0481] A chiral nematic liquid crystal composition CLC-A2 comprising the nematic liquid crystal composition NLC-A (96.5% by weight) and the chiral agent (8H) BN-H5 (3.5% by weight) was obtained.

[0482] The phase transition temperature (℃) of the chiral nematic liquid crystal composition CLC-A2 is N * 79.8 BP-I.

[0483] Preparation of the mixture (MLC-A2) of polymerizable monomer and chiral nematic liquid crystal composition

[0484] As a mixture of chiral nematic liquid crystal composition and polymerizable monomer, 88.8% by weight of chiral nematic liquid crystal composition CLC-A2, 6.0% by weight of n-hexadecyl acrylate, and 4.8% by weight of benzene-1 , 2,4-triyltris(4-(12-(acryloyloxy)dodecyloxy)benzoyloxy)benzoate (LCA-1), 0.4% by weight as photopolymerized Initiator 2,2'- dimethoxyphenyl acetophenone mixed mixture MLC-A2. The phase transition temperature (℃) of the mixture MLC-A2 is N * 52.5BP-I.

[0485] Preparation of polymer / liquid crystal composite material (...

Embodiment 3

[0489] A nematic liquid crystal composition NLC-B was prepared by mixing the liquid crystal compounds shown in the figure below in the following ratios.

[0490] Nematic liquid crystal composition NLC-B

[0491]

[0492]

[0493] The phase transition temperature (° C.) of the nematic liquid crystal composition NLC-B is N 97.1I.

[0494] Next, a chiral nematic liquid crystal composition CLC-B comprising a nematic liquid crystal composition NLC-B (96.5% by weight) and a chiral agent (8H) BN-H5 (3.5% by weight) was obtained.

[0495] The phase transition temperature (℃) of the chiral nematic liquid crystal composition CLC-B is N * 90.4BP-I.

[0496] Preparation of the mixture (MLC-B) of polymerizable monomer and chiral nematic liquid crystal composition

[0497] As a mixture of chiral nematic liquid crystal composition and polymerizable monomer, 88.8% by weight of chiral nematic liquid crystal composition CLC-B, 6.0% by weight of n-dodecyl acrylate, and 4.8% by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com