Rotating joint and oil cylinder hinge base integrated oil cylinder

A rotary joint, one-piece technology, applied in the field of oil cylinder hinge seat integrated oil cylinder and rotary joint, can solve the problems of difficulty in adjusting the unified height of multi-sector dam surfaces, slow dam surfaces, and inability to maintain a horizontal plane on the dam surface, and achieve extended maintenance. Cycle, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

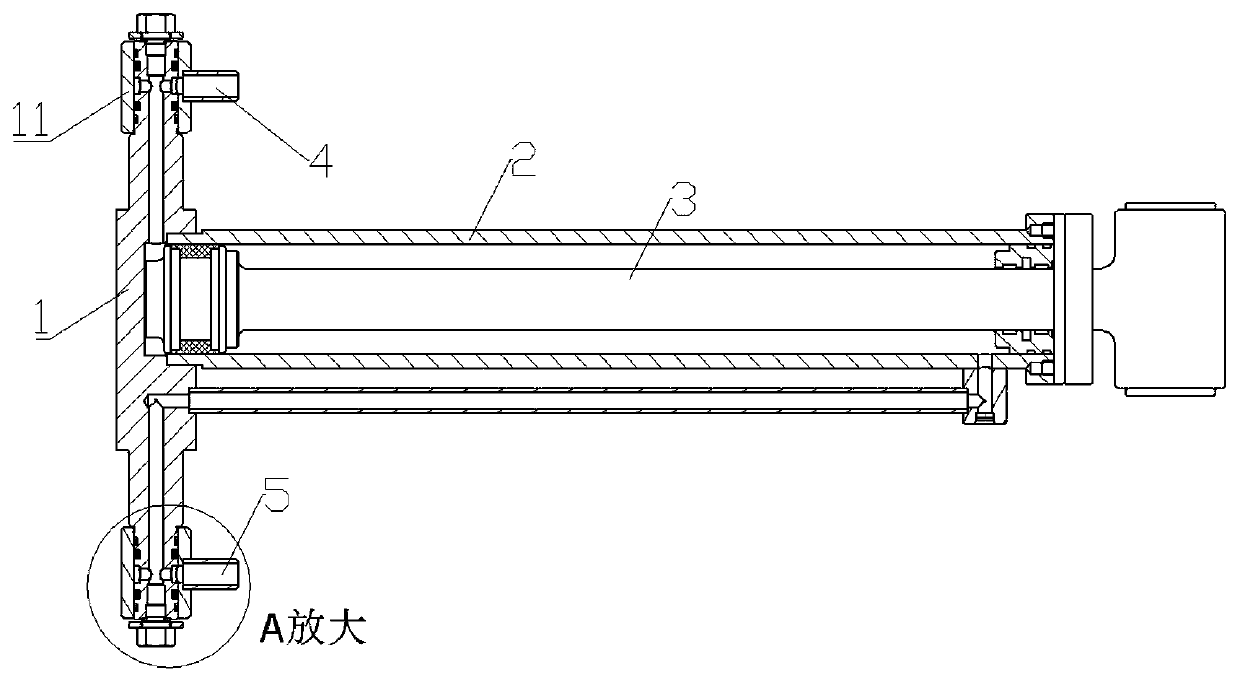

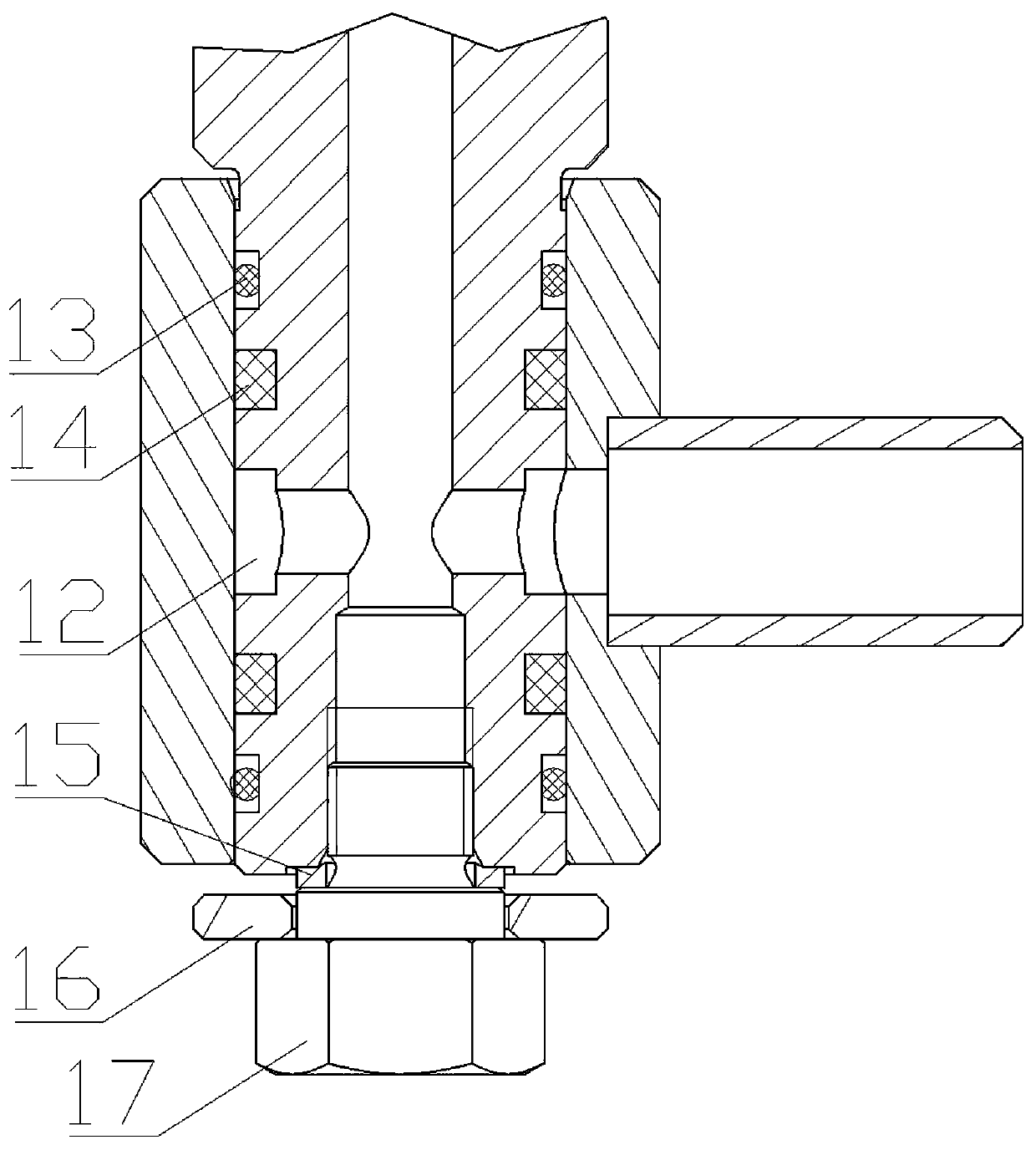

[0016] Embodiment 1, refer to Figure 1 to Figure 2 , the present invention includes an oil cylinder hinge seat integrated rotary joint 1, a cylinder body 2, a piston rod 3, a rodless chamber pipeline 4 and a rod chamber pipeline 5, and the piston rod 3 is set in the cylinder body 2, so that the cylinder body forms a The rod cavity and the rodless cavity, the rodless cavity pipeline 4 and the rod cavity pipeline 5 are installed on both ends of the rotary joint 1 of the oil cylinder hinge seat through the rotary joint sleeve 11, and respectively pass through the oil channel and the rodless cavity and the rod cavity. Cavities are connected, through the reversing valve in the hydraulic station, the oil inlet and outlet switching of the rodless cavity pipeline and the rod cavity pipeline is realized, so that the oil cylinder can be extended or retracted.

Embodiment 2

[0017] Embodiment 2, refer to Figure 1 to Figure 2 , the oil cylinder hinge seat integrated rotary joint 1 is provided with oil passages respectively connecting the rodless cavity pipeline 4 and the rodless cavity, and the rod cavity pipeline 5 and the stainless steel pipes coming out of the rod cavity. The rest are the same as any other embodiment of the present invention or the combination of more than two embodiments.

Embodiment 3

[0018] Embodiment 3, refer to Figure 1 to Figure 2 An annular gap 12 is provided in the integrated rotary joint 1 of the oil cylinder hinge seat, so that the oil channel in the integrated rotary joint 1 of the oil cylinder hinge seat is connected with the rotary joint sleeve 11, and the rotary joint sleeve 11 is connected with the rodless chamber pipeline 4 or There is a rod lumen pipeline 5 in communication. The rest are the same as any other embodiment of the present invention or the combination of more than two embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com