Baseline-free detection and location method of steel plate defects with welded seams based on impaired reciprocity

A positioning method and reciprocity technology, applied in the field of non-baseline detection and positioning of steel plate defects with welded seams based on impaired reciprocity, can solve the problems of difficult acquisition of baseline data, achieve accurate positioning, high engineering application value, Imaging results are clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

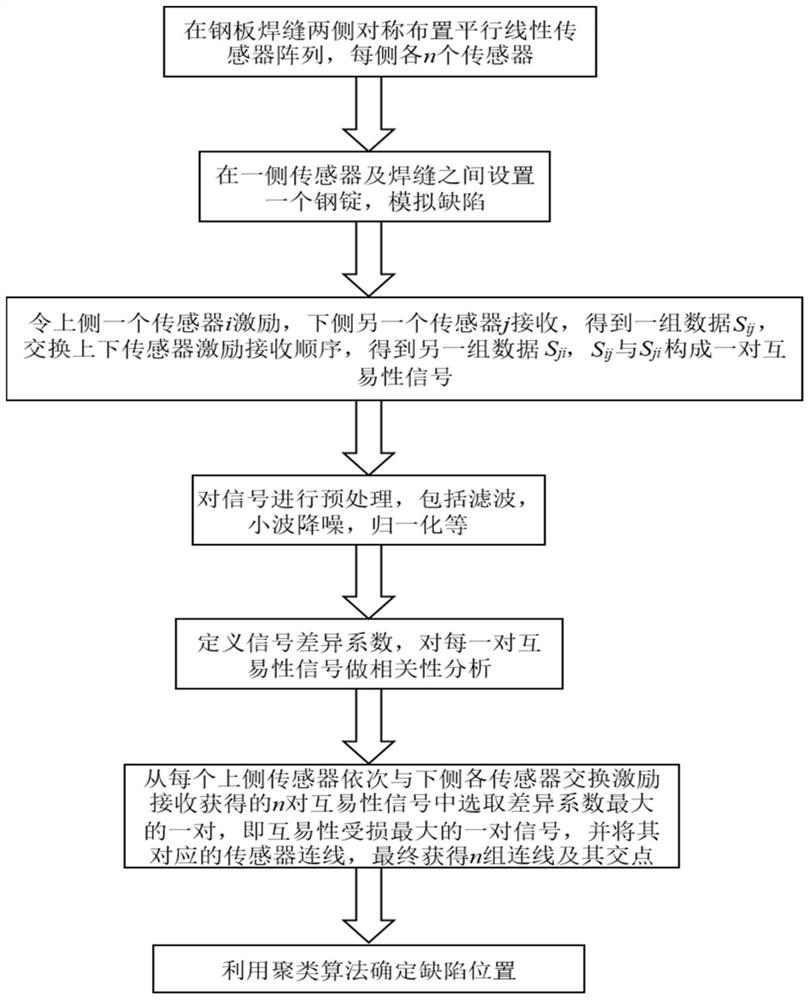

[0047] figure 1 It is a flow chart of the present invention. like figure 1 As shown, this example provides a method for baseline-free detection and location of defects in welded steel plates based on impaired reciprocity, including the following steps:

[0048] Step 1: Collect the guided wave detection signal in the welded steel plate, the specific steps are as follows:

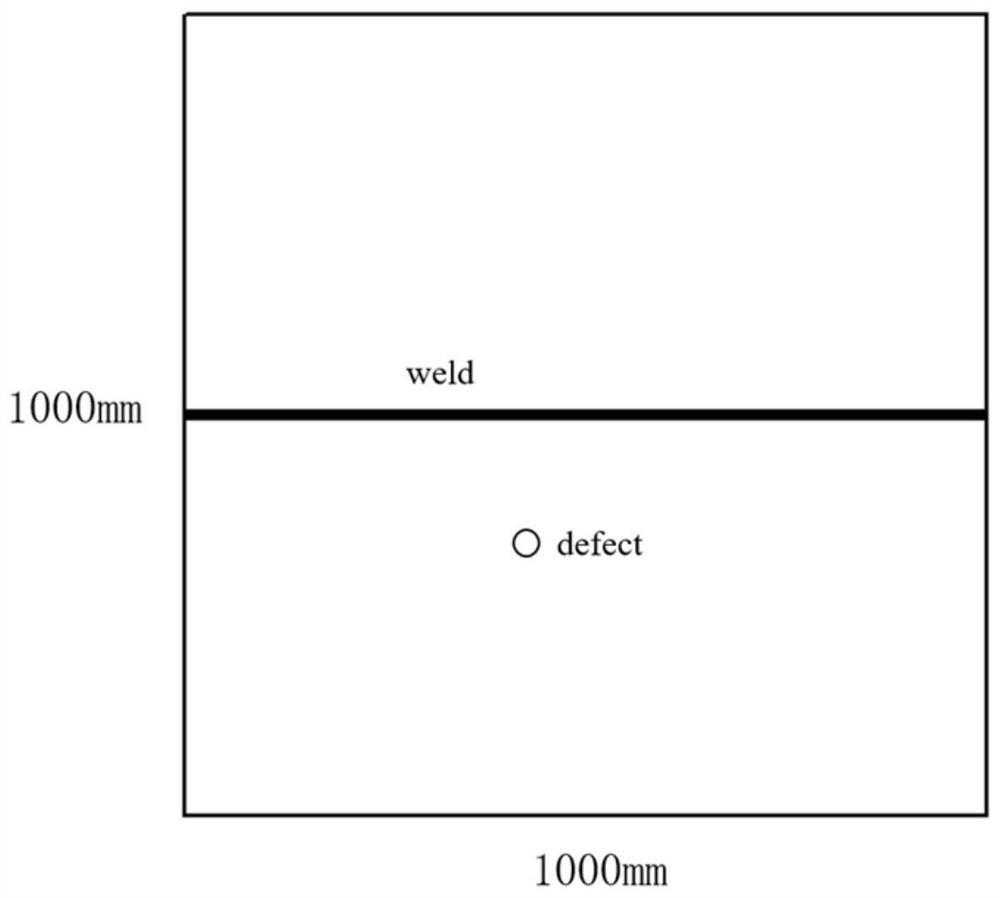

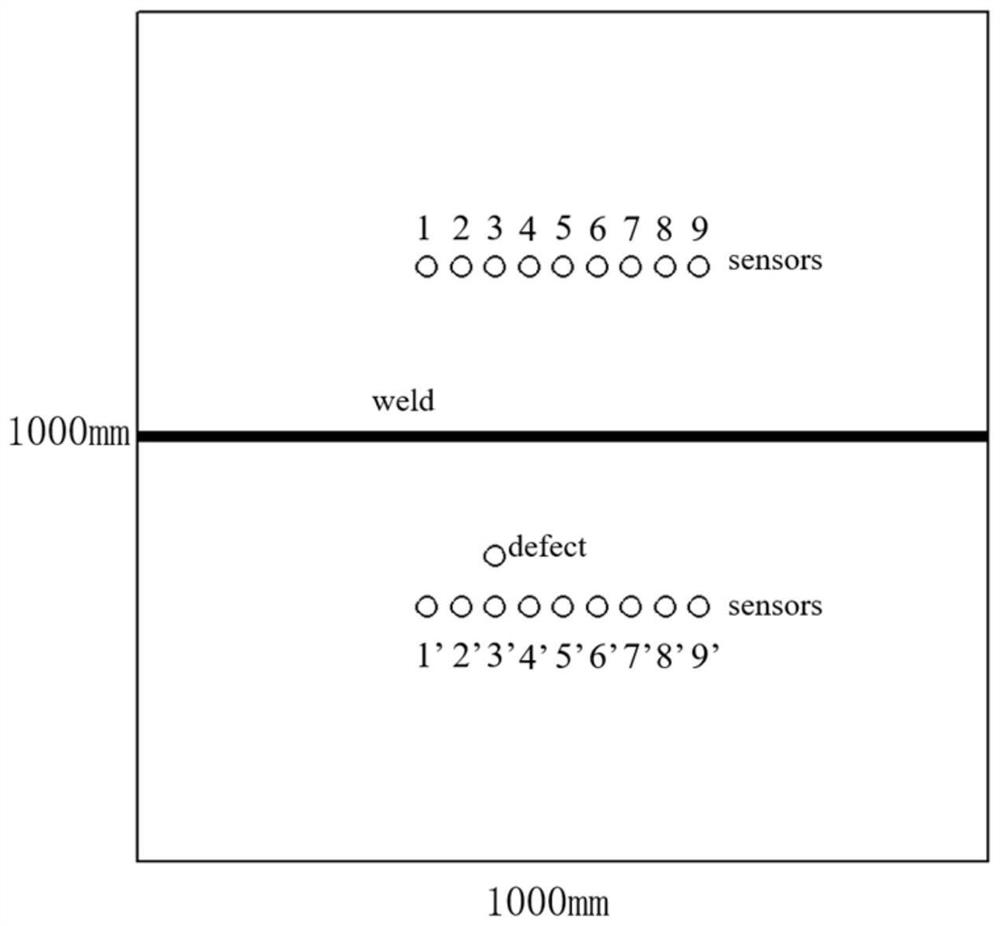

[0049] Step 1-1: Arrange 18 (n=9) piezoelectric wafer sensors on a 1000mm×1000mm×3mm steel plate with welded seams, the diameter of the piezoelectric wafer is 10mm, and the thickness is 1mm. Among them, the welding seam is in the center of the steel plate, the lower left corner of the steel plate is taken as the coordinate origin to establish a rectangular coordinate system, and a steel ingot is set between the sensor on one side and the welding seam, the diameter of the steel ingot is 10mm, and the defects are simulated, and the coordinates are (420, 360), such as figure 2 (weld means weld in the figure,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com