Feeding control method, material storage device, cooking utensil and storage medium

A control method and technology of a storage device, which are applied to steam cooking utensils, the structure of cooking utensils, cooking utensils, etc., can solve the problems of long feeding time and low feeding efficiency, and reduce the amount of materials, reduce the operating power, and improve the feeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

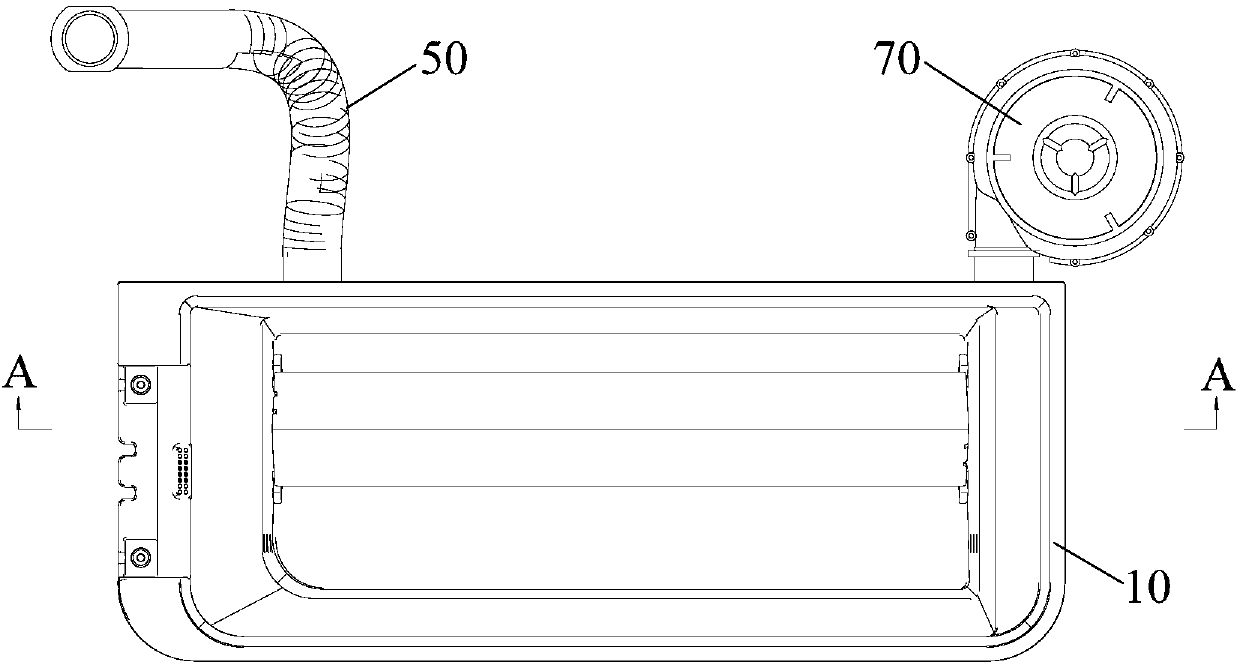

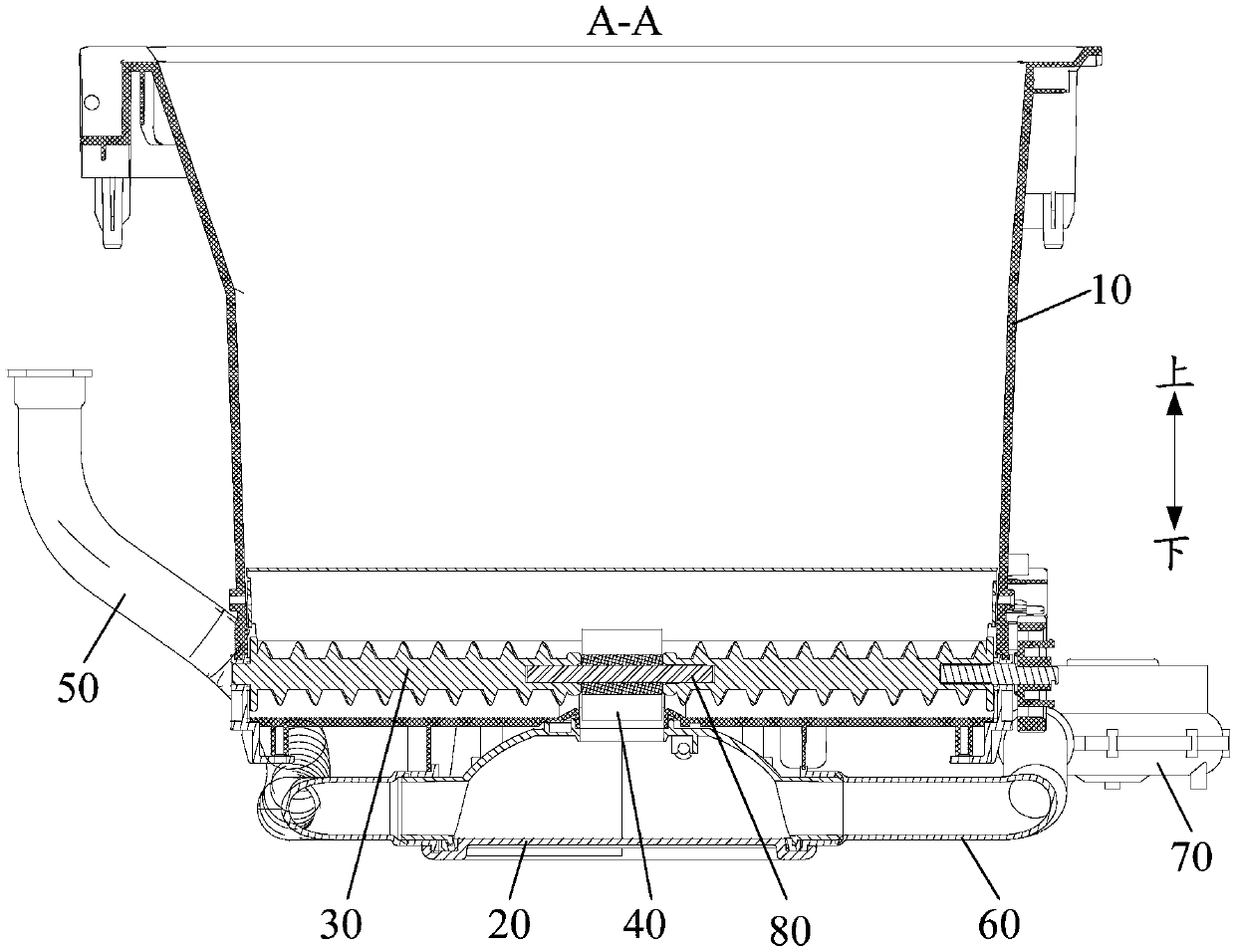

Embodiment 1

[0065] In the above embodiment, before the discharge port is closed, the step of turning on the power part so that the material entering the transfer cavity is discharged through the discharge port of the transfer cavity is specifically: while opening the discharge port, turn on the power components, so that the materials entering the transfer chamber 20 are discharged through the outlet of the transfer chamber 20 .

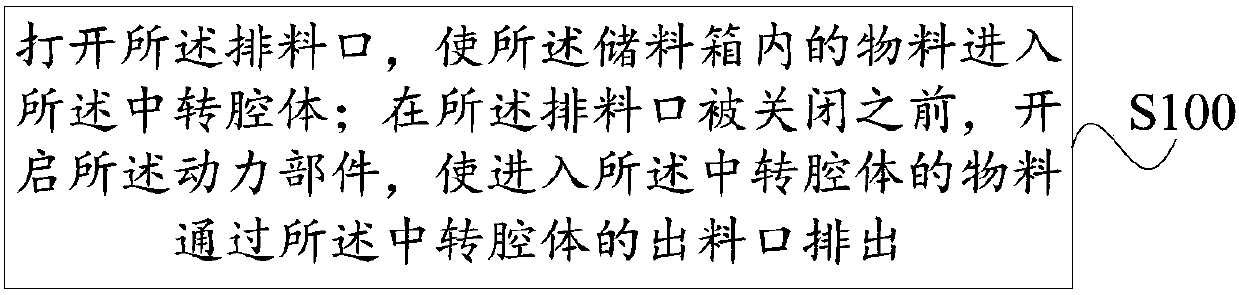

[0066] In other words, if Figure 4 As shown, the feeding control method specifically includes:

[0067] Step S102: Open the discharge port so that the materials in the material storage box enter the transfer cavity, and at the same time turn on the power components so that the materials entering the transfer cavity 20 are discharged through the discharge port of the transfer cavity 20 .

[0068] While opening the discharge port, turn on the power part, so that the material storage process of the storage box 10 and the material output process of the transfer cav...

Embodiment 2

[0070] The difference from Embodiment 1 is that: before the discharge port is closed, the step of turning on the power part, so that the material entering the transfer cavity is discharged through the discharge port of the transfer cavity, specifically: before opening the discharge port, opening The power part enables the material entering the transfer cavity 20 to be discharged through the discharge port of the transfer cavity 20 after the discharge port is opened.

[0071] In other words, if Figure 5 As shown, the feeding control method specifically includes:

[0072] Step S104: Turn on the power component, so that the material entering the transfer cavity 20 after the discharge port is opened can be discharged through the discharge port of the transfer cavity 20;

[0073] Step S106: Open the discharge port so that the materials in the storage box enter the transfer cavity.

[0074] Before opening the discharge port, the power unit is turned on to ensure that the material...

Embodiment 3

[0076] The difference with Embodiment 1 or Embodiment 2 is that: on the basis of Embodiment 1 or Embodiment 2, the material storage device further includes a feeding mechanism arranged in the storage box 10 for promoting material discharge; feeding control Methods also include:

[0077] Before the discharge port is closed, the unloading mechanism is turned on.

[0078] The material storage device also includes an unloading mechanism, and before the discharge port is closed, the unloading mechanism is opened to ensure that the unloading mechanism can participate in the unloading process of the storage box 10, thereby further improving the unloading efficiency of the storage box 10 , and further improve the feeding efficiency and further shorten the feeding time.

[0079] Preferably, before the discharge opening is closed, the step of opening the unloading mechanism is specifically: opening the unloading mechanism while opening the discharge opening.

[0080] In other words, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com