Thin-wall high-position-precision hole system component machining method

A part processing and high position technology, which is applied in the determination and adjustment of multiple factors and parameters, can solve the problems of excessive precision and size, low production qualification, etc., and achieve the effect of improving stability and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

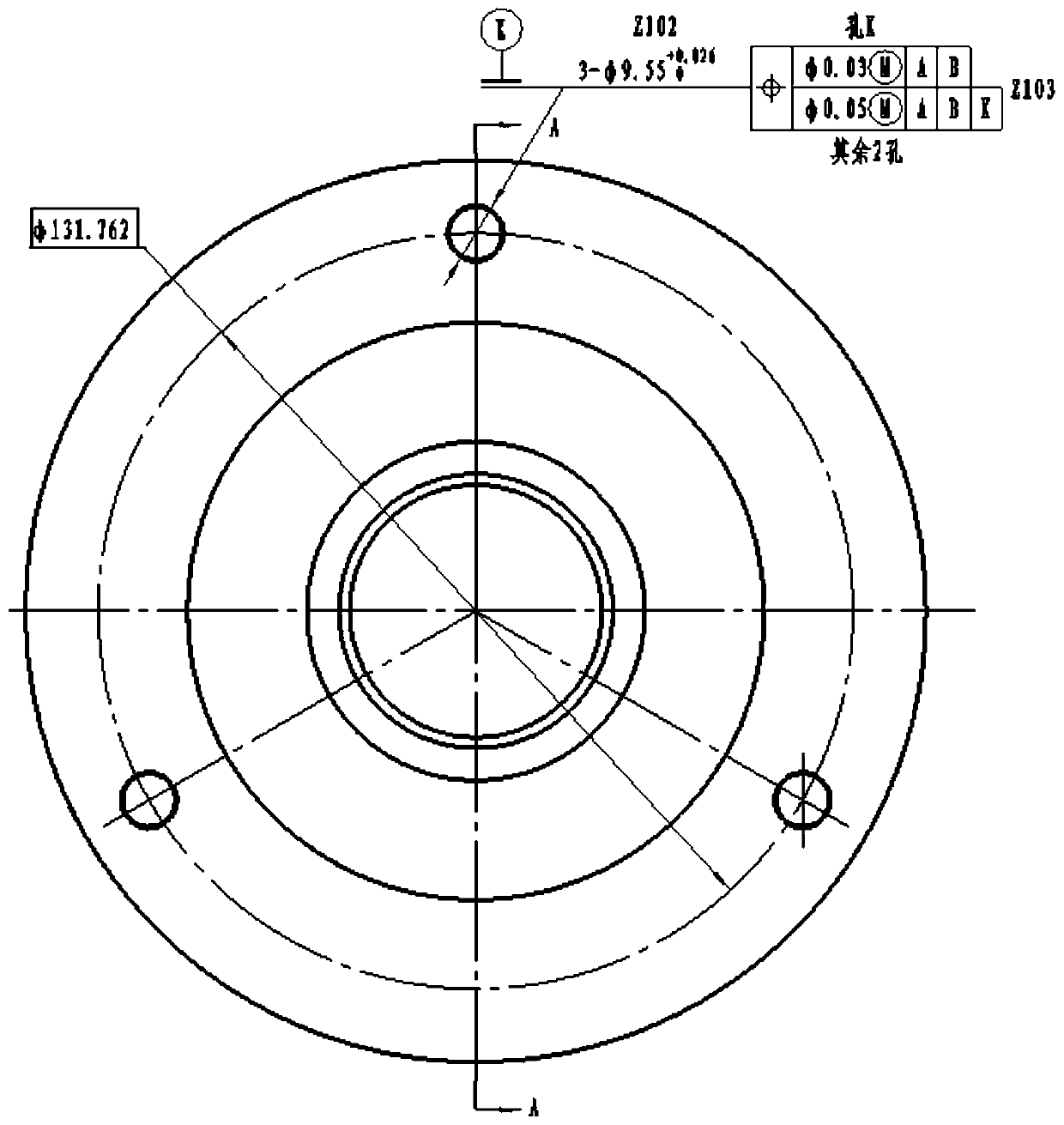

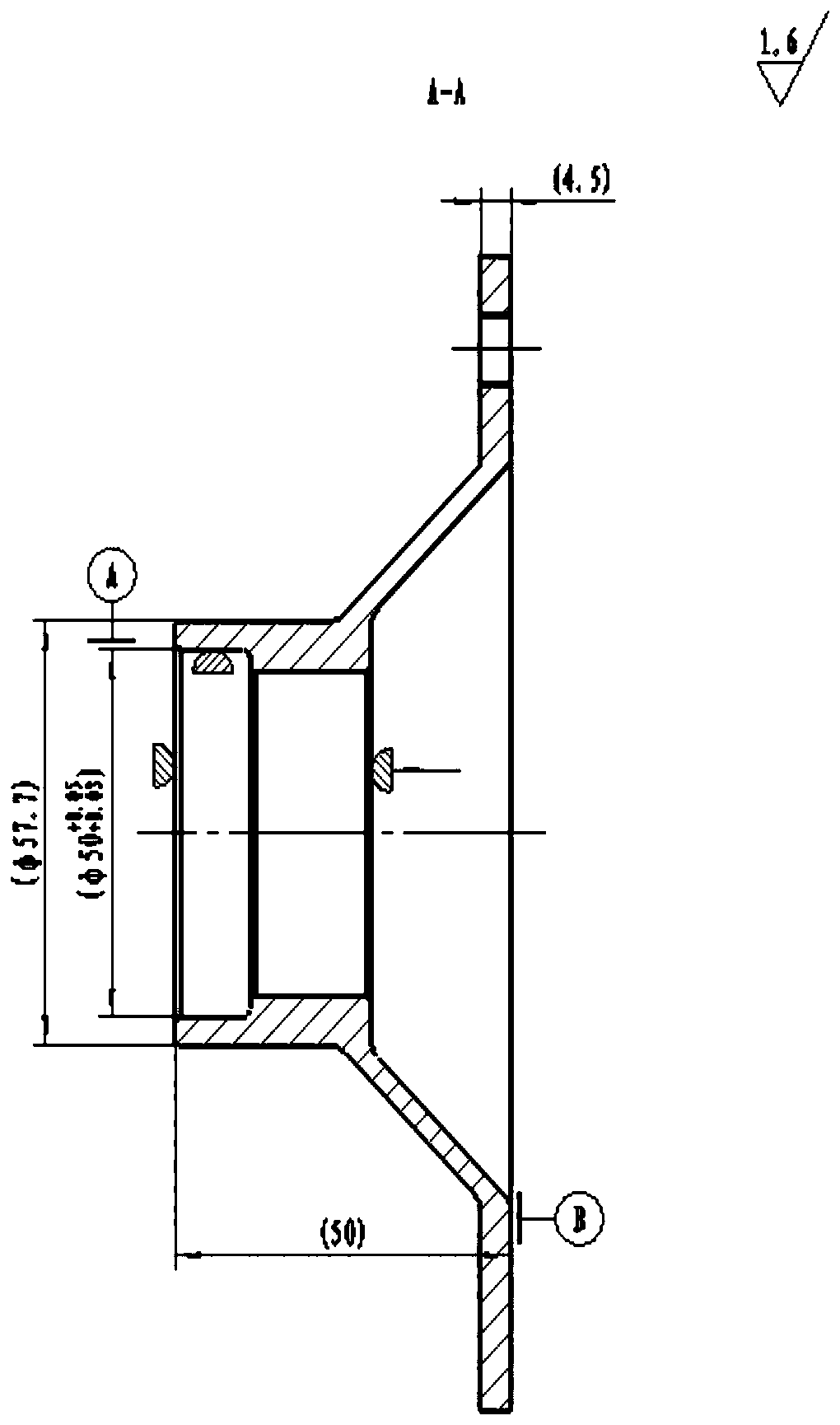

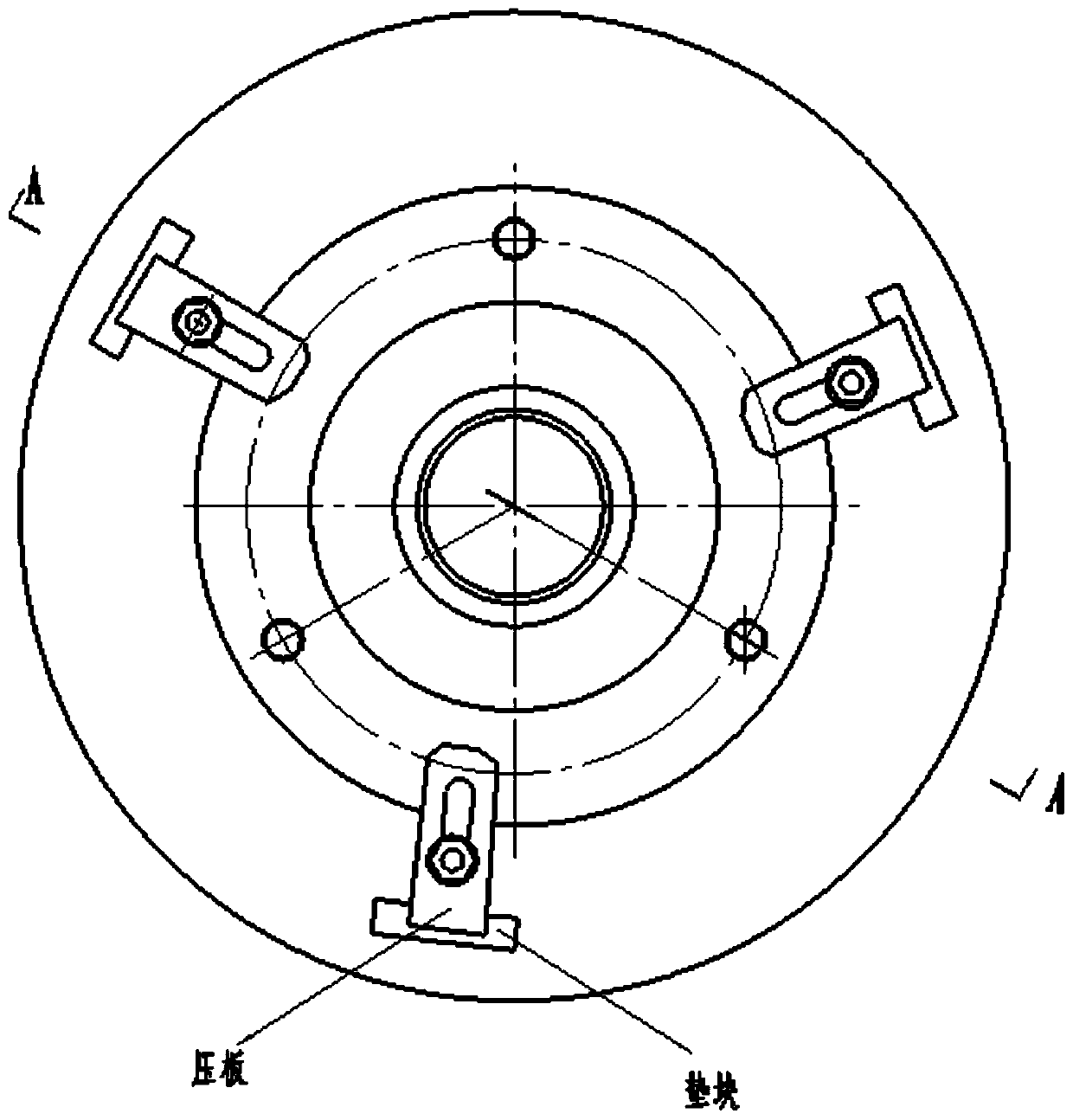

[0046] This embodiment is processing parts as attached figure 1 with figure 2 As shown, in an aerospace field, thin-walled, ultra-thin-walled hole system parts with high positional accuracy requirements, the specific technology should refer to the attached figure 1 with figure 2 , using the technological method described in the present invention can accurately position and process.

[0047] 1. Difficulty analysis: According to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com