Indexing mechanism for oil pump assembly, oil pump tightening machine and oil pump assembly method

An indexing mechanism and oil pump technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low degree of automation, reduce labor costs, improve work efficiency, and facilitate disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] First of all, it should be noted that the equipment disclosed in this embodiment is applied to the assembly and production of the oil delivery pump 3-5, and the implementation object of this embodiment is the oil delivery pump 3-5 in the assembly process, which specifically includes the pump head 3 -5-1 and the pump body, this embodiment will realize the connection between the pump head 3-5-1 and the pump body.

[0051] Please refer to Figure 6 ~ Figure 8 , this embodiment discloses an indexing mechanism for oil pump assembly, including an indexing plate 3-1, a first plate sleeve 3-2, a clamping seat 3-7, a second plate sleeve, and a second plate sleeve sliding sleeve Connected in the first plate cover 3-2, the first plate cover 3-2 can reciprocate along the extension direction of the second plate cover, and the second plate cover can fix the pump head 3-5-1 of the oil delivery pump 3-5 ;

[0052] Among them, please refer to Image 6 , the indexing plate 3-1 is a ci...

Embodiment 2

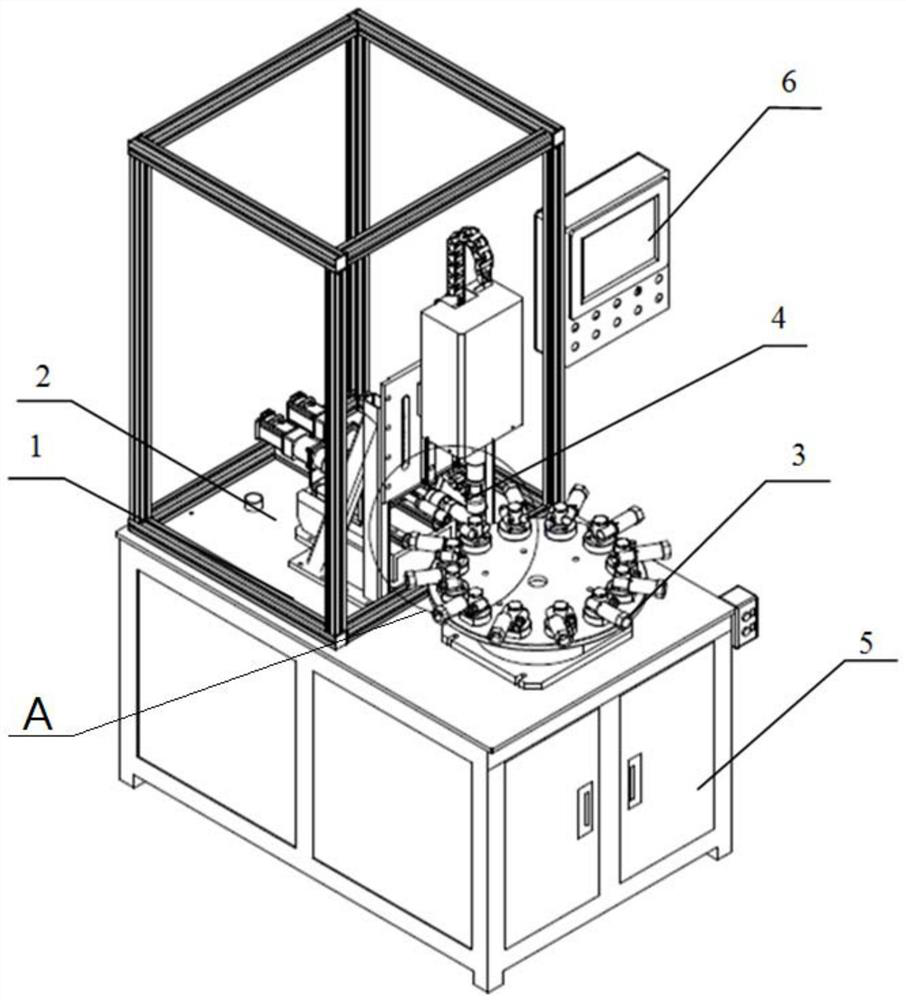

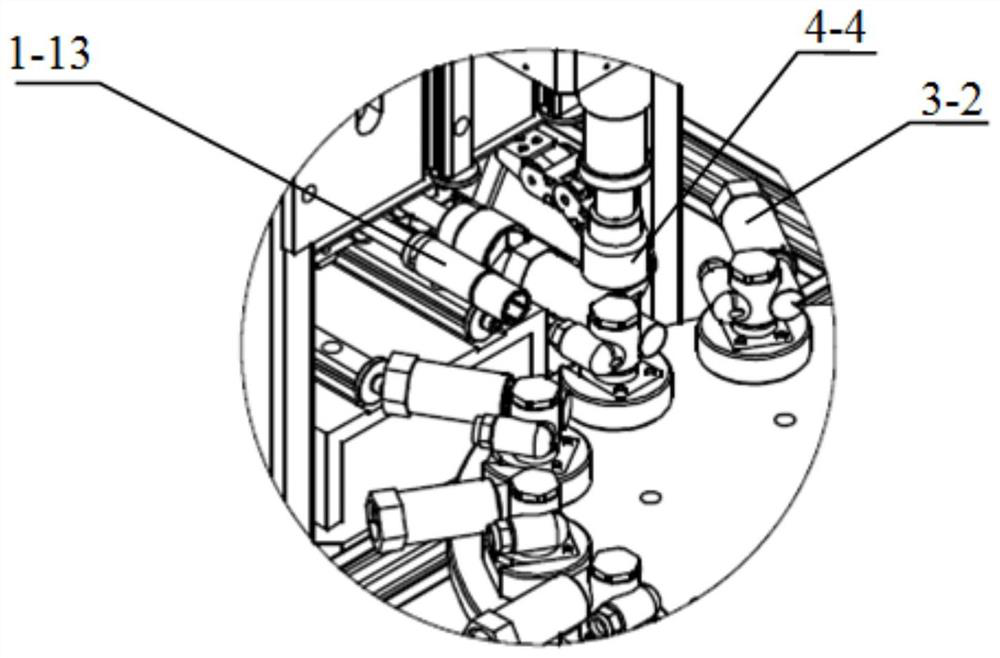

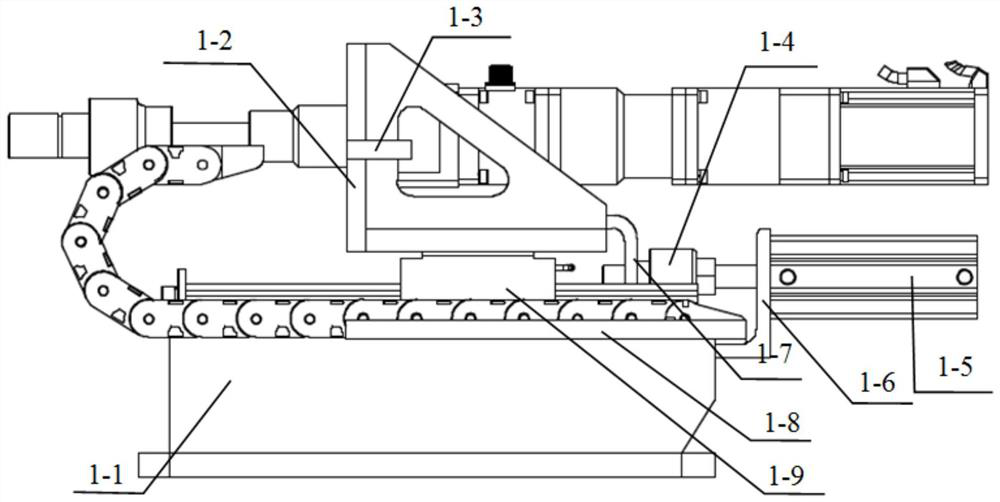

[0064] Please refer to Figure 1 to Figure 9 , this embodiment discloses an oil delivery pump tightening machine, comprising a workbench 5, a first tightening assembly 1, a second tightening assembly 4 and an indexing mechanism 3 for assembling an oil delivery pump as disclosed in Embodiment 1, and the workbench 5 is installed There is an indexing mechanism 3, the first tightening assembly 1 and the second tightening assembly 4 are installed on the workbench 5, and the movement direction of the actuator of the first tightening assembly 1 and the actuator of the second tightening assembly 4 are perpendicular to each other; the first tightening assembly The executive sub-mechanism of component 1 can be socketed in the horizontal direction of the oil pump 3-5 to be tightened, and the executive sub-mechanism of the second tightening assembly 4 can be socketed in the vertical direction of the oil pump 3-5 to be tightened. the bolt;

[0065] When the indexing mechanism 3 rotates, t...

Embodiment 3

[0081] Embodiment 3 discloses a fuel pump assembly method based on Embodiment 2, comprising the following steps:

[0082] First install the second plate sleeve and the first plate sleeve 3-2 on the pump head 3-5-1 respectively, and then complete the positioning of the first plate sleeve 3-2 and the second plate sleeve through the cylindrical positioning pin 3-4 , and then install the pump head 3-5-1 in the workpiece matching seat, and fix it with straight pins. After completing the tooling assembly of the oil pump 3-5, install it on the indexing plate 3-1;

[0083] Start the tightening mechanism. First, the cylinder in the second tightening assembly 4 controls the tightening shaft to descend, and the bolt on the upper end of the oil delivery pump 3-5 (that is, the vertical bolt of the oil delivery pump 3-5) is passed through the third outer hexagonal sleeve 4-4. Cooperate to realize the fixation of the oil delivery pump 3-5, the first cylinder 1-5 drives the first tightening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com