A method for pressure transfer molding of composite materials and a pressing mold

A technology of composite materials and transfer molding, which is applied in the field of methods and pressing molds, and pressure transfer molding of composite materials, can solve the problems of increased cost, high manufacturing cost, and high energy consumption, and achieve reduction of manufacturing cycle and cost, improvement of mechanical strength, and guarantee effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

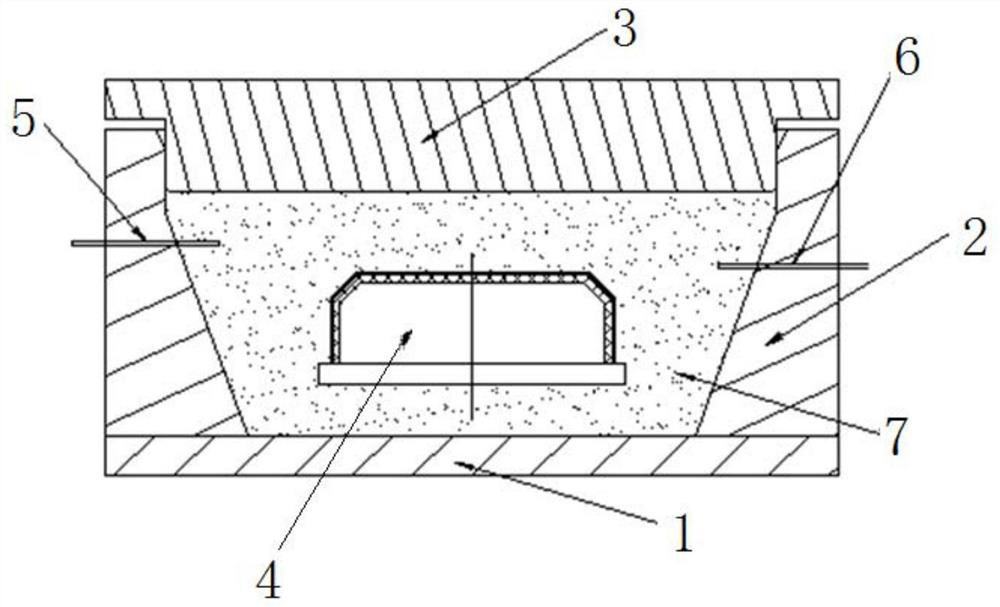

[0034] This example is suitable for situations where the external dimensions and appearance of the product are required to be high, and the cost of making punches is saved. It is mainly suitable for small products, usually with a projected area below 150mm×200mm.

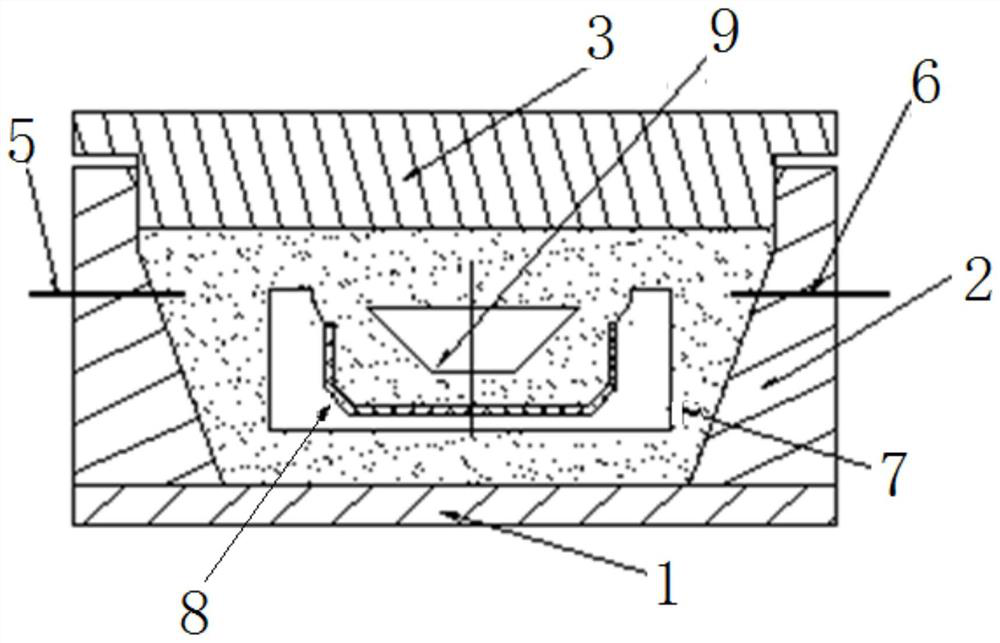

[0035] Example 2 is the standard method of die forming. On the basis of Example 1, the punch is replaced with a concave cavity 8 and a movable pressing block 9 . The side surface of the movable pressing block is an inclined surface, and the mouth of the cavity 8 of the die is a trumpet-shaped opening.

[0036] Using the above-mentioned pressing mold, the forming method includes the following steps: 1) According to the commonly used product specifications, manufacture a compression cavity 2 and a pressure plate 3 that can be used within a certain range; 2) Make a special model for wrapping; 3) Lay the blank, Prepreg or fiber cloth is laid in the cavity 8 of the concave mold, and resin is brushed, and then a breatha...

Embodiment 3

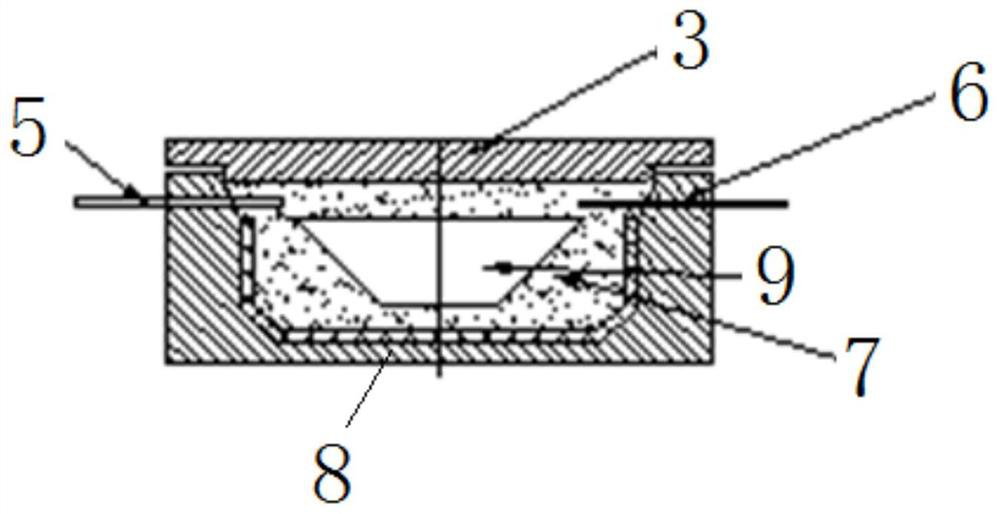

[0037] This embodiment is the same as Embodiment 2, and is suitable for situations where the external dimensions and appearance of the product are required to be high. It is suitable for large products (usually the projected area is above 150mm×200mm), and the production of compression chambers can be omitted.

[0038]Example 3, as a modification of Example 2, is a simple die-forming method. The pressing plate 3 matched with the concave mold cavity 8 is made. There is a bell mouth on the upper part of the concave mold cavity 8, and the mouth is provided with a matching section that can be covered with the lower edge of the pressing plate 3. Part of the transfer material 7 is poured into the concave mold cavity, and then moved The pressing block 9 is placed inside the concave mold cavity 8, fills and flattens the transfer object 7, compresses the pressing plate 3, and performs the subsequent molding operation. The above three embodiments are used to press and form the composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com