Continuous pressurizing belt type dehydrator and dehydration method

A belt-type dewatering and crawler technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of poor operation stability of filter press crawler, bulky equipment, and short service life of filter press crawler. and other problems, to achieve the effect of self-adaptive adjustment, reduction of finishing weight, and reduction of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

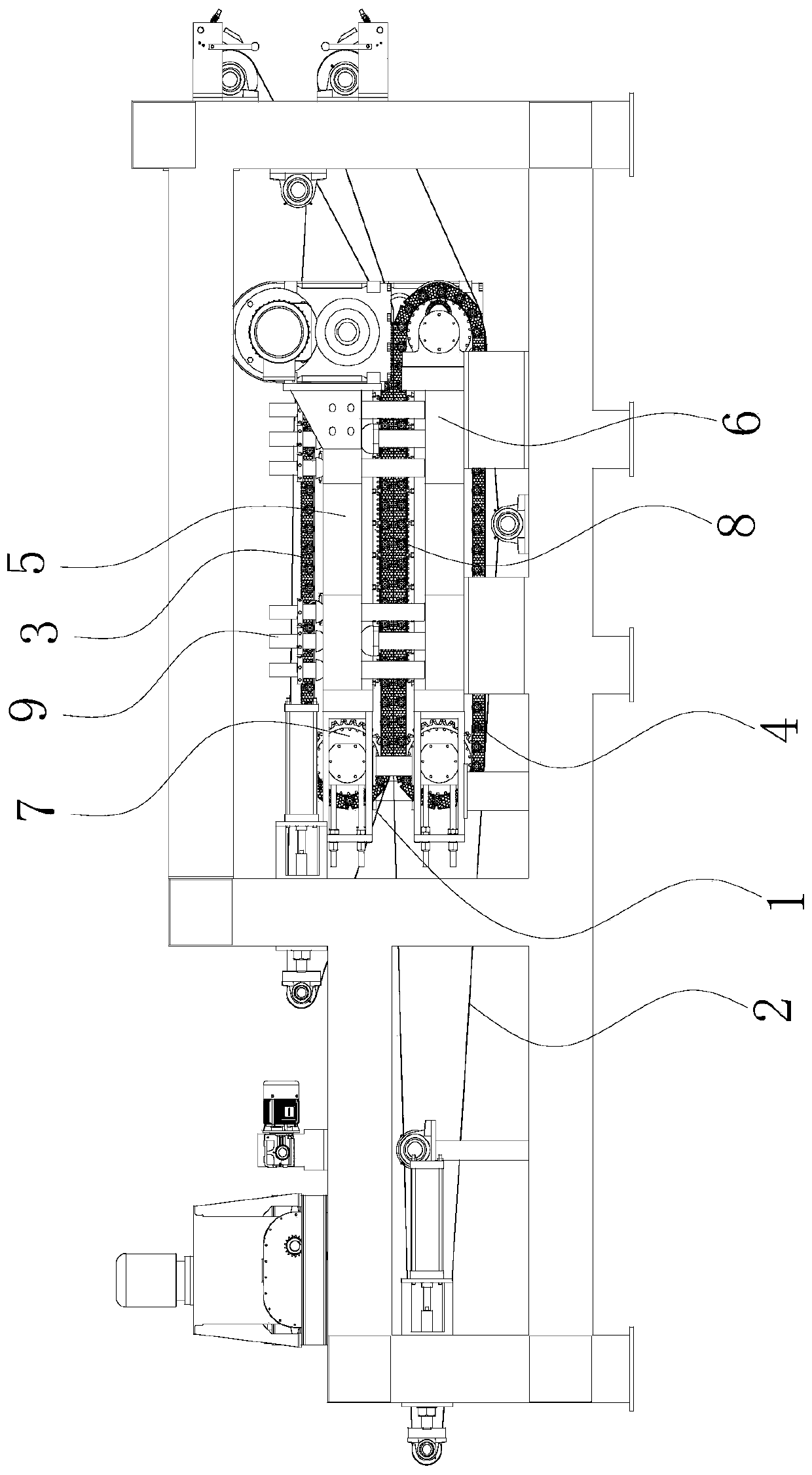

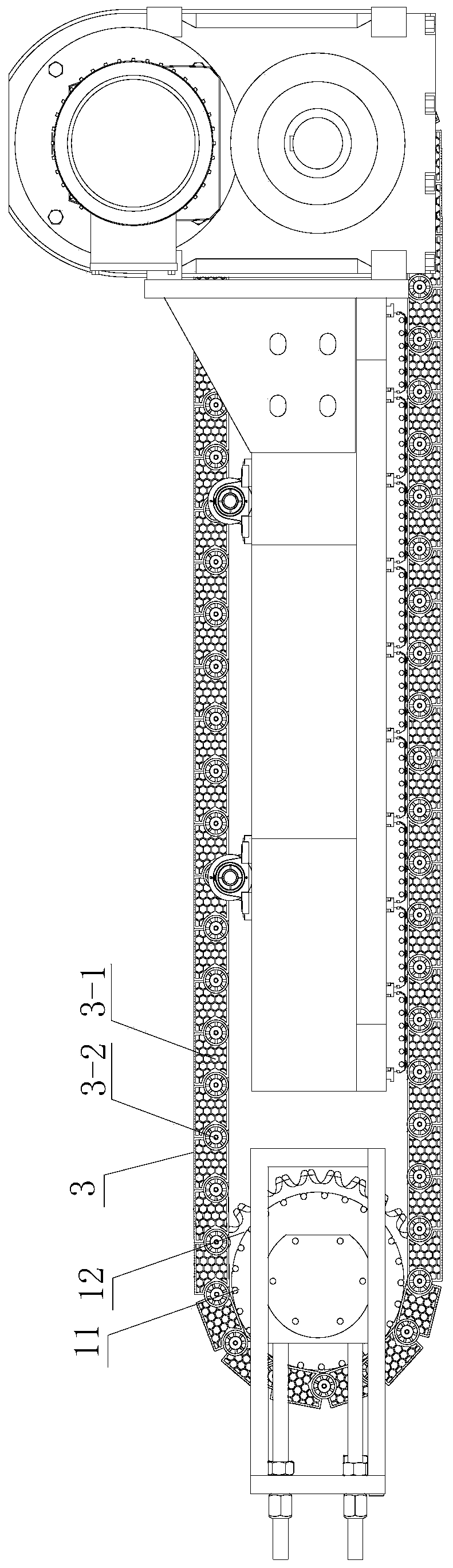

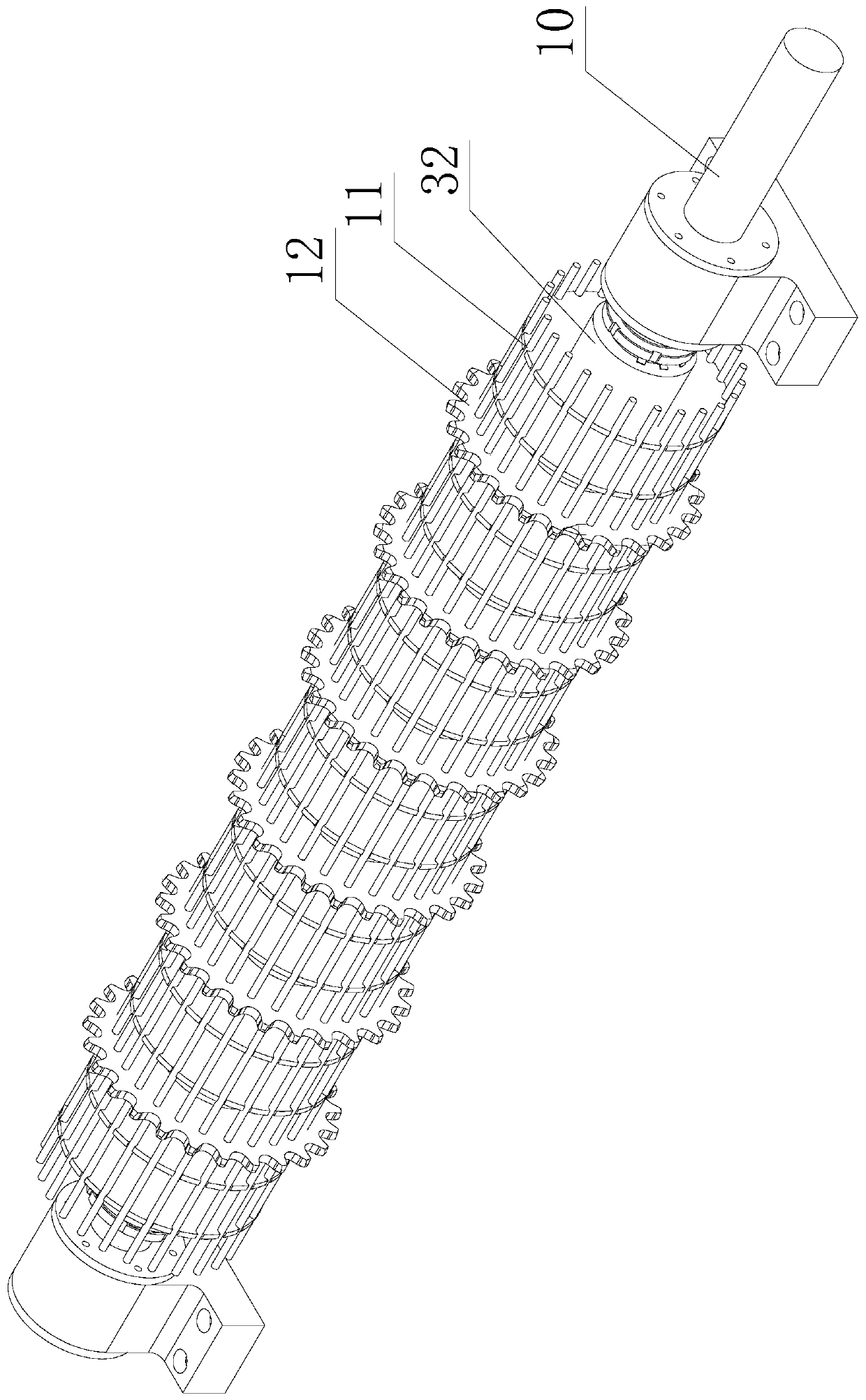

[0051] A kind of continuous pressurized belt dehydrator of present embodiment, as figure 1 or figure 2 As shown, it includes upper filter screen 1, lower filter screen 2, upper filter press track 3, lower filter press track 4, upper track support 5 and lower track support 6, the upper filter press track is installed on the upper track support, and the lower filter press track The track is installed on the lower track bracket, the upper filter is tensioned on the outer periphery of the upper filter press track, and the lower filter is tensioned on the outer periphery of the lower filter press track. Along the sludge conveying direction, a height is formed between the upper filter and the lower filter. Tapered wedge filter press zone. In this continuous pressurized dehydrator, the upper and lower filter press crawlers are respectively equipped with crawler belt transmission mechanisms 7 with the same structure. Rolling auxiliary transmission mechanisms 8 are respectively prov...

Embodiment 2

[0084] This embodiment is a continuous pressurized belt dehydrator. Compared with Embodiment 1, the difference is that in the crawler belt transmission mechanism, the support part is in the shape of a roller as a whole, and the two ends or / and the inner side of the support part are connected to the The mounting sleeves are connected by bearings. The support part of this structure has a better load-bearing effect and can better ensure the stability of equipment operation, but its weight will be larger than that of the cage structure of the same specification, which will increase the equipment cost.

Embodiment 3

[0086] This embodiment is a continuous pressurized belt dehydrator. Compared with Embodiment 1, the difference is that in the rolling auxiliary transmission mechanism, the partition in the installation frame is a combined structure, including the partition body and The upper fixing strip, and the through slots with upper openings are distributed on the bulkhead body (for the structure, please refer to Figure 6 ), each through-slot is correspondingly connected with a connecting shaft, and the same connecting shaft passes through the through-slot at the corresponding position on each bulkhead body; an upper fixing bar is provided on the top of the bulkhead body, and the upper fixing bar covers the opening of each through-slot above. When installing the partitions of this structure, first connect the rolling parts in series on the connecting shaft, then put them into the corresponding through grooves on the main body of each partition, and then cover the openings of the through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com