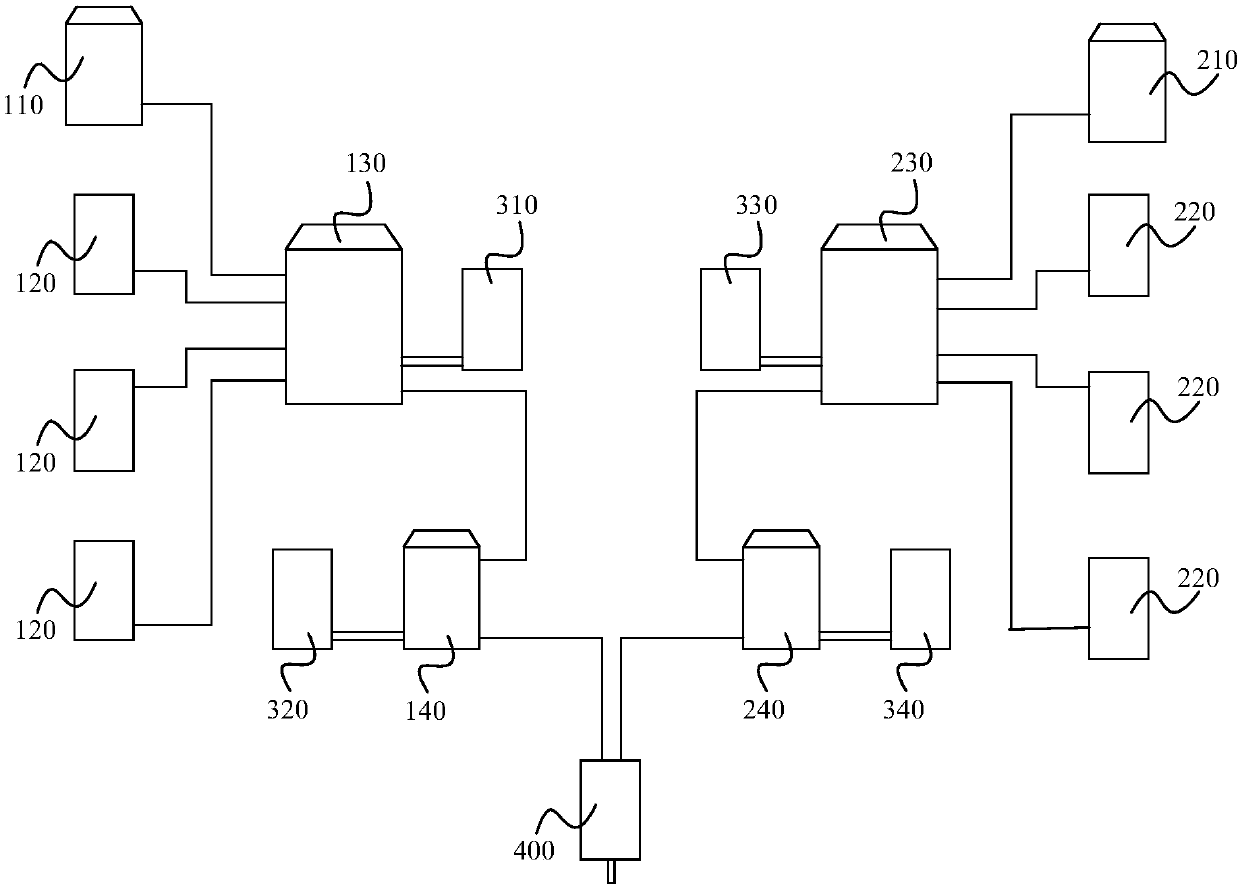

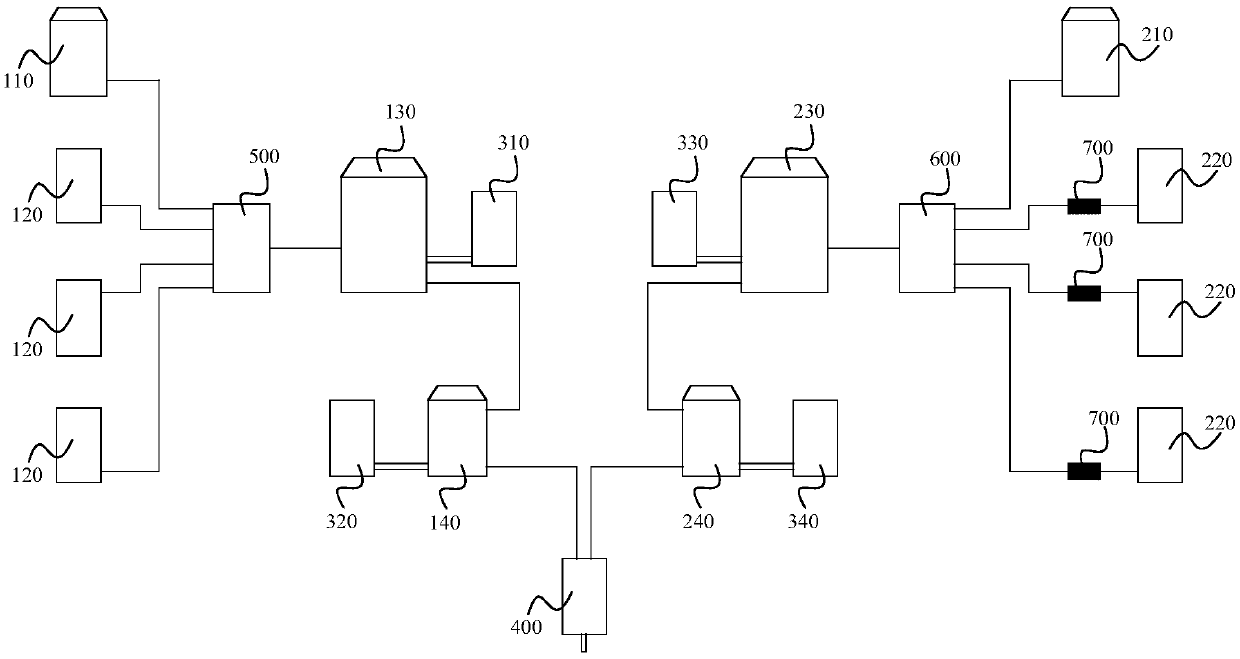

Multi-element premixed foaming device and method

A foaming device and premixing technology, applied in the field of household appliance production technology, can solve problems to be improved, etc., and achieve the effects of widening the selection range, reducing density and foam thermal conductivity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

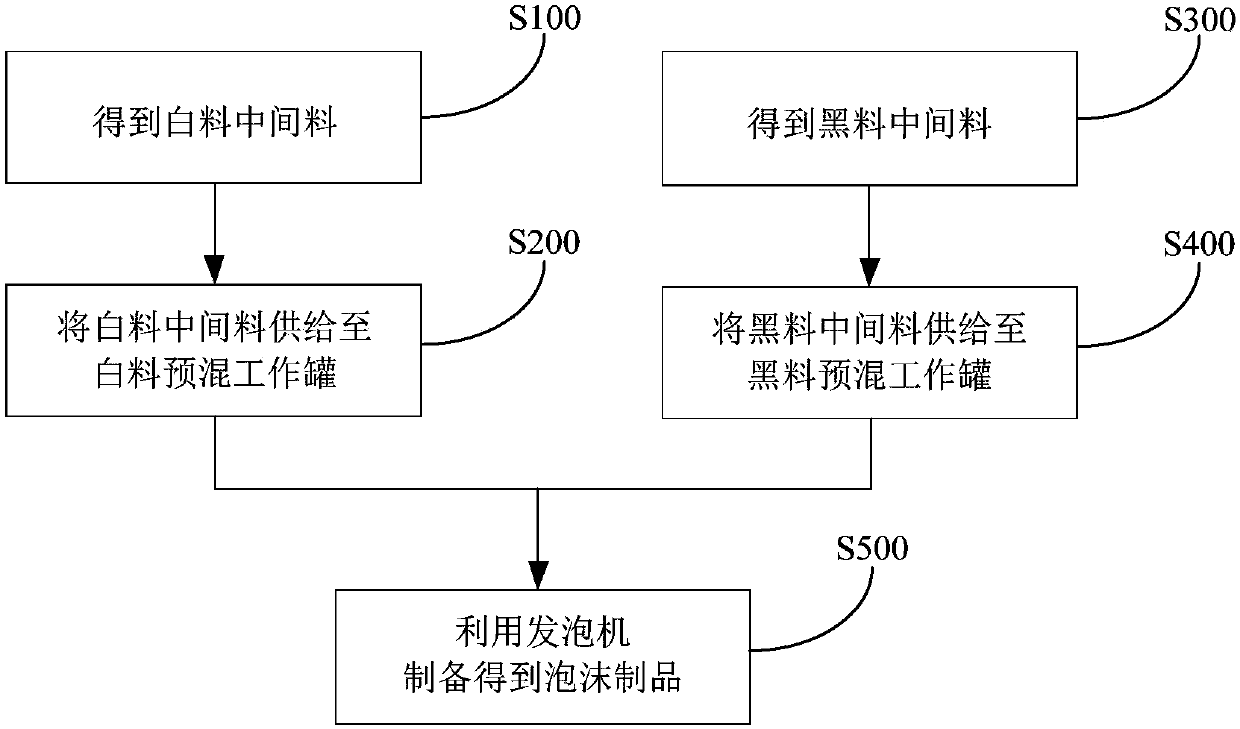

Method used

Image

Examples

Embodiment 1

[0088] The multi-component premixing foaming device and foaming method of the present invention are used to prepare foam products, wherein the white material premixing system adopts polyol composite material, and the high boiling point foaming agent adopts cyclopentane and HFC-245fa; the black material premixing system Isocyanates are used, and HCFO-1233zd and R134a are used as low-boiling blowing agents. The foaming process conditions are set as:

[0089] The material temperature of the black material tundish is 5°C, and that of the white material tundish is 35°C;

[0090] The material temperature of the black material working tank is 5°C, and the material temperature of the white material working tank is 32°C.

Embodiment 2

[0092] Foam products are prepared by adopting the multi-component premixing foaming device and foaming method of the present invention, wherein the white material premixing system adopts polyol composite material, and the high boiling point foaming agent adopts cyclopentane and HFC-365mfc; the black material premixing system Isocyanates are used, and HFC-245fa and HFO-1234ze are used as low-boiling blowing agents. The foaming process conditions are set as:

[0093] The material temperature of the black material tundish is 15°C, and that of the white material tundish is 25°C;

[0094] The material temperature of the black material working tank is 15°C, and the material temperature of the white material working tank is 25°C.

Embodiment 3

[0096] Foam products are prepared by adopting the multi-component premixing foaming device and foaming method of the present invention, wherein the white material premixing system adopts polyol composite material, and the high boiling point foaming agent adopts cyclopentane and HFO-1336mzz; the black material premixing system Isocyanates are used, and HCFO-1233zd, methyl formate and R134a are used as low-boiling blowing agents. The foaming process conditions are set as:

[0097] The material temperature of the black material tundish is 5°C, and that of the white material tundish is 20°C;

[0098] The material temperature of the black material working tank is 0°C, and the material temperature of the white material working tank is 18°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com