Preparation and application of a solar-driven self-heating multi-stage sulfide in situ grown black sponge

A technology of in-situ growth and black sponge, applied in chemical instruments and methods, separation methods, liquid separation, etc., to achieve the effects of reducing environmental pollution, increasing surface roughness, and super-hydrophobic and super-lipophilic capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

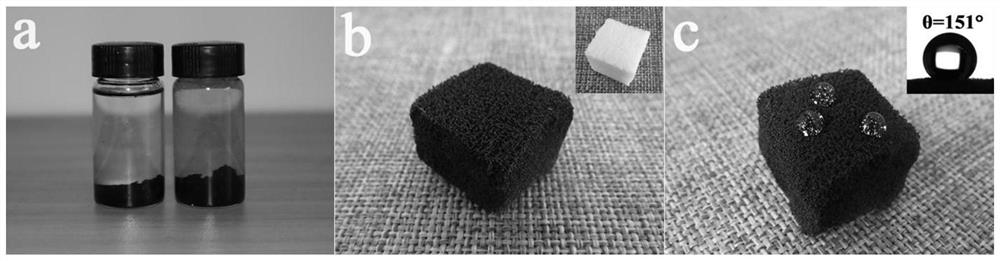

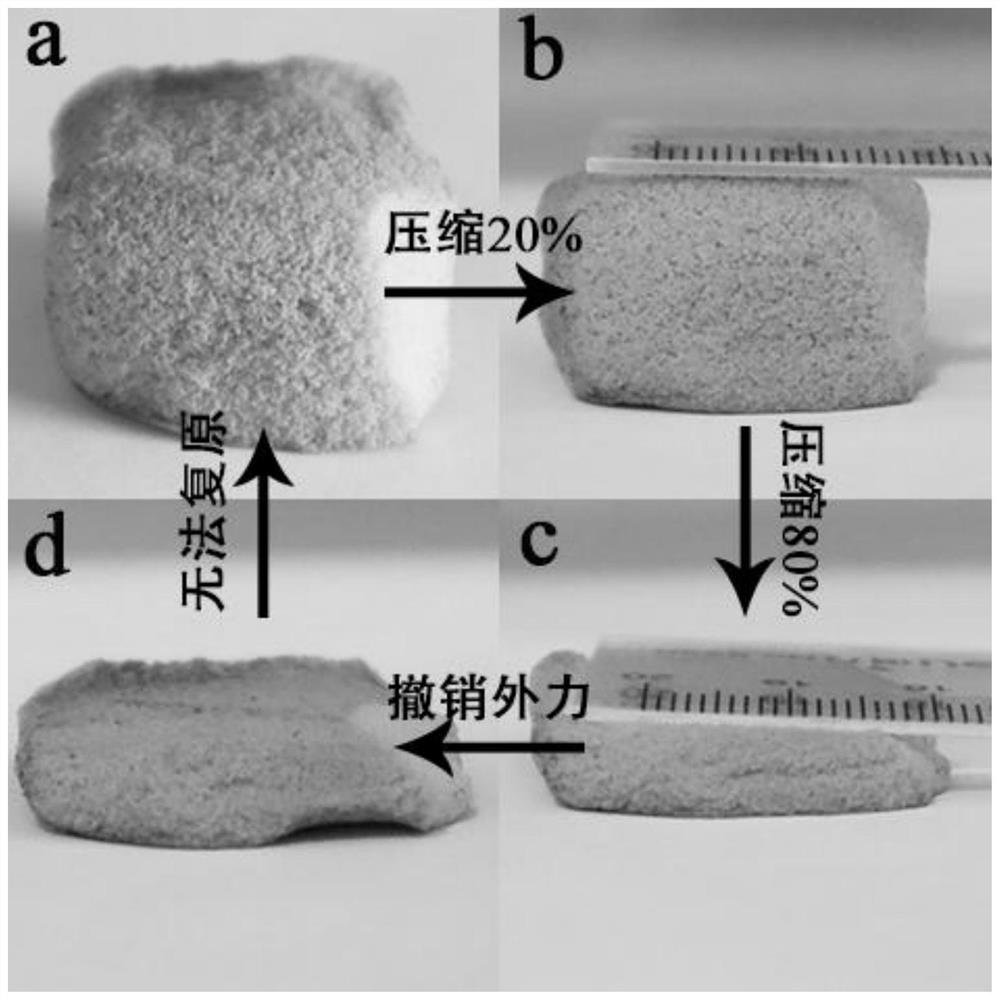

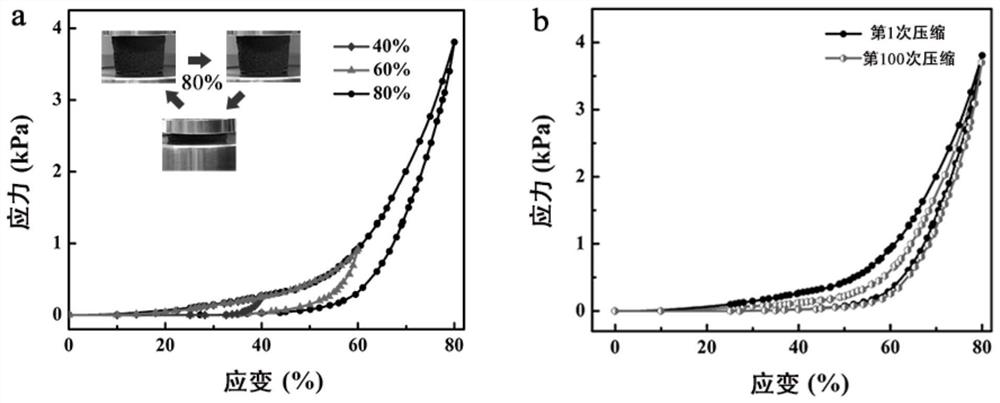

[0045] (1) Dissolve 0.5g of tungsten hexachloride and 1g of thioacetamide in 30mL of deionized water, and stir for 30min at 1000rpm to form a colorless and clear solution; using waste rubber sponge as raw material, waste rubber sponge Cut it to a size of 1cm×2cm×1cm, put it into the reaction kettle after immersing in the colorless and clear solution, pour the colorless and clear solution into the reaction kettle, perform a hydrothermal reaction at 180°C for 12 hours, wash with absolute ethanol after the reaction Clean, remove residual impurities, place in an oven, and dry at 50°C to obtain a black block;

[0046] (2) Weigh 0.05g of ammonium molybdate and 0.2g of thiourea and disperse them in 30mL of deionized water, stir at 1000rpm for 30min to obtain a colorless and transparent solution, immerse in a black block, and then transfer to the reaction kettle , hydrothermally reacted at 180°C for 16 hours. After the reaction, it was first washed with absolute ethanol and then deion...

Embodiment 2

[0048] (1) Dissolve 1g of tungsten hexachloride and 1.5g of thioacetamide in 50mL of deionized water, and stir for 20min at 1500rpm to form a colorless and clear solution; using waste rubber sponge as raw material, waste rubber Cut the sponge to a size of 1cm×2cm×1cm, put it into the reaction kettle after being immersed in the colorless and clear solution, pour the colorless and clear solution into the reaction kettle, and perform a hydrothermal reaction at 200°C for 16 hours, then wash with absolute ethanol Wash, remove residual impurities, place in an oven, and dry at 60°C to obtain a black block;

[0049] (2) Weigh 0.15g of ammonium molybdate and 0.2g of thiourea and disperse them in 50mL of deionized water, stir for 40min at 2000rpm to obtain a colorless and transparent solution, immerse in a black block, and then transfer to the reaction kettle , hydrothermal reaction at 200°C for 18 hours, after the reaction, wash with absolute ethanol, then with deionized water to remov...

Embodiment 3

[0051] (1) Weigh 0.8g of tungsten hexachloride and 1.5g of thioacetamide and dissolve them in 50mL of deionized water, and stir for 30min at 2000rpm to form a colorless and clear solution; using waste rubber sponge as raw material, waste Cut the rubber sponge to a size of 1cm×2cm×1cm, put it into the reaction kettle after being immersed in the colorless and clear solution, pour the colorless and clear solution into the reaction kettle, and conduct a hydrothermal reaction at 230°C for 24 hours. Wash with ethanol to remove residual impurities, place in an oven, and dry at 70°C to obtain a black block;

[0052] (2) Weigh 0.08g of ammonium molybdate and 0.16g of thiourea and disperse them in 50mL of deionized water, stir for 60min at a speed of 3000rpm to obtain a colorless and transparent solution, immerse in a black block, and then transfer to the reaction kettle , hydrothermal reaction at 210°C for 20 hours, after the reaction, wash with absolute ethanol, then with deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com