White oil usable as shock absorber oil and preparation method thereof

A technology of shock absorber oil and white oil, which is applied in the direction of processing hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., can solve the problems of high mining cost of naphthenic crude oil and high cost of naphthenic oil, so as to reduce production cost, Improved stability and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

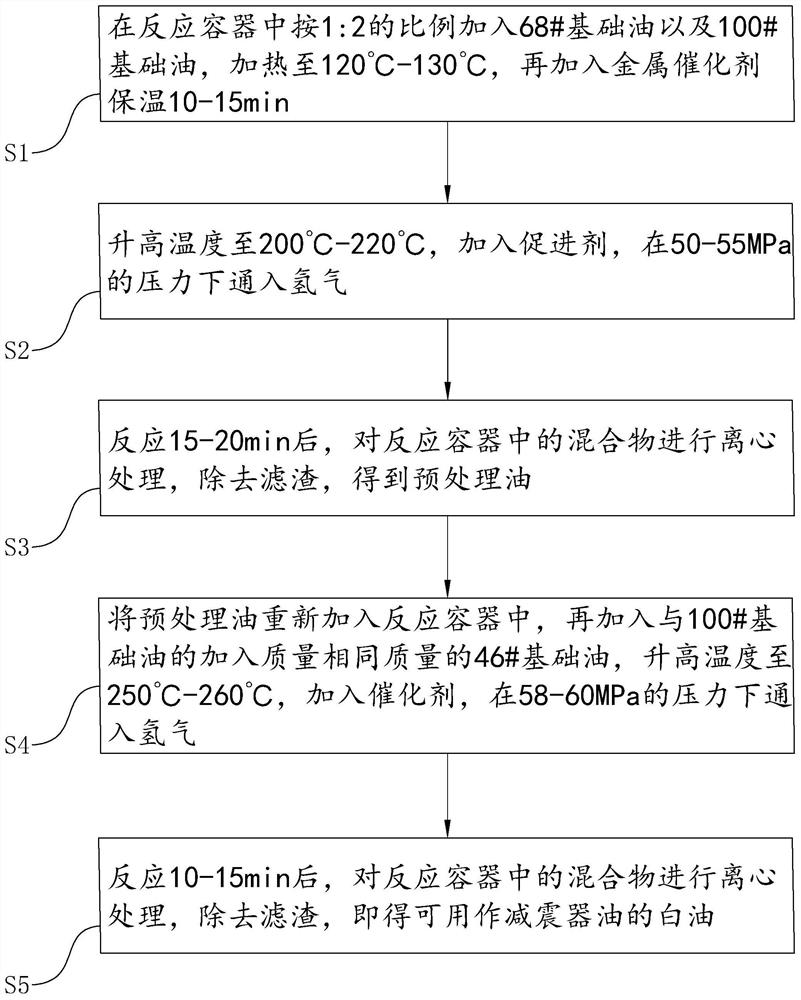

Method used

Image

Examples

Embodiment 1

[0052] A white oil that can be used as a shock absorber oil, comprising the following steps:

[0053] S1. Add 20kg of 68# base oil and 40kg of 100# base oil into a closed 100L reactor, stir evenly, heat to 120°C, then add 90g of zinc catalyst and keep it warm for 15min;

[0054] S2. Raise the temperature to 200°C, then add attapulgite 360g, stir evenly, pass a hydrogen flow under a pressure of 50MPa, and control the flow rate of the hydrogen flow to 100g / min;

[0055] S3. After reacting for 20 minutes, the raw materials in the reactor were extracted and centrifuged to remove filter residues to obtain pretreated oil;

[0056] S4. Re-add the pretreated oil into the reaction kettle, then add 40kg of 100# base oil, and raise the temperature to 250°C, add 1.1kg of Cistanche deserticola extract, stir evenly, introduce hydrogen flow under the pressure of 58MPa, and control The feed rate of hydrogen flow is 120g / min;

[0057] S5. After reacting for 15 minutes, extract the mixture in...

Embodiment 2

[0059] A white oil that can be used as a shock absorber oil, comprising the following steps:

[0060] S1. Add 20kg68# base oil and 40kg100# base oil into a closed 100L reactor, stir evenly, heat to 125°C, then add 90g of zinc catalyst and keep it warm for 13min;

[0061] S2. Raise the temperature to 210°C, then add attapulgite 360g, stir evenly, pass a hydrogen flow under a pressure of 53MPa, and control the flow rate of the hydrogen flow to 100g / min;

[0062] S3. After reacting for 18 minutes, the raw materials in the reactor were extracted and centrifuged to remove filter residues to obtain pretreated oil;

[0063] S4. Re-add the pretreated oil into the reaction kettle, then add 40kg of 100# base oil, and raise the temperature to 255°C, add 1.1kg of Cistanche deserticola extract, stir evenly, introduce hydrogen flow under the pressure of 59MPa, and control The feed rate of hydrogen flow is 120g / min;

[0064] S5. After reacting for 12 minutes, extract the mixture in the rea...

Embodiment 3

[0066] A white oil that can be used as a shock absorber oil, comprising the following steps:

[0067] S1. Add 20kg68# base oil and 40kg100# base oil into a closed 100L reactor, stir evenly, heat to 130°C, then add 90g of zinc catalyst and keep it warm for 10min;

[0068] S2. Raise the temperature to 220°C, then add attapulgite 360g, stir evenly, pass a hydrogen flow under a pressure of 55MPa, and control the flow rate of the hydrogen flow to 100g / min;

[0069] S3. After reacting for 15 minutes, the raw materials in the reactor were extracted and centrifuged to remove filter residues to obtain pretreated oil;

[0070] S4. Re-add the pretreated oil into the reactor, then add 40kg of 100# base oil, and raise the temperature to 260°C, add 1.1kg of Cistanche deserticola extract, stir evenly, introduce hydrogen flow under the pressure of 60MPa, and control The feed rate of hydrogen flow is 120g / min;

[0071] S5. After reacting for 10 minutes, extract the mixture in the reactor and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com