A kind of mosquito repellent fabric finishing liquid, mosquito repellent finishing fabric and preparation method

A fabric finishing and mosquito repelling technology, which is applied in the field of mosquito repellent fabric finishing solution, mosquito repellent finishing fabric and preparation, and can solve the problems of environmental pollution, poor washability, exhaustion of matrix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

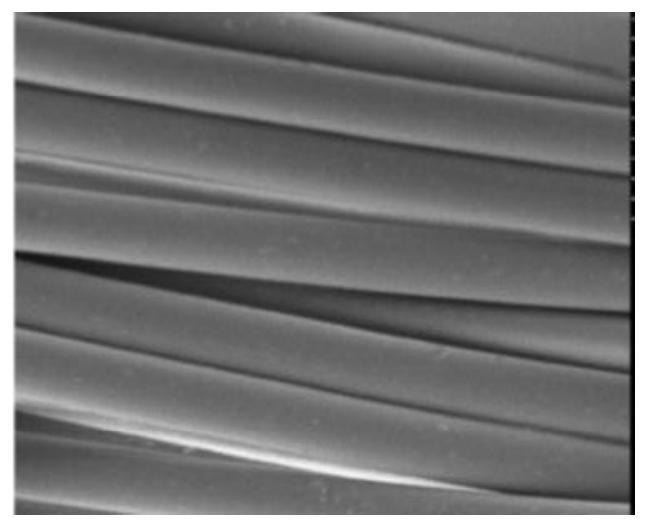

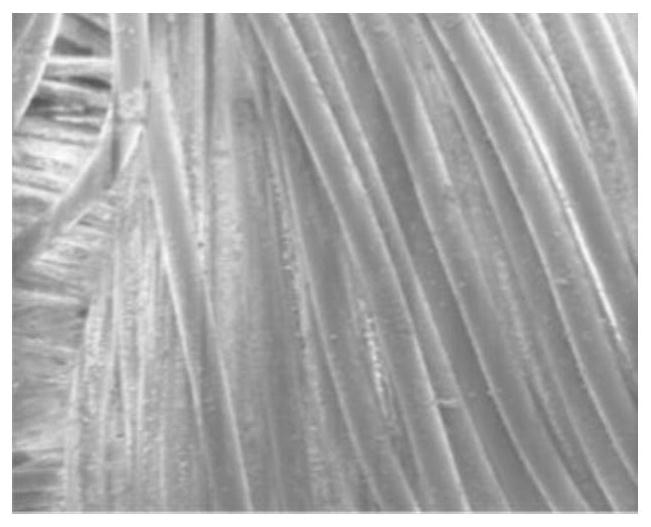

Image

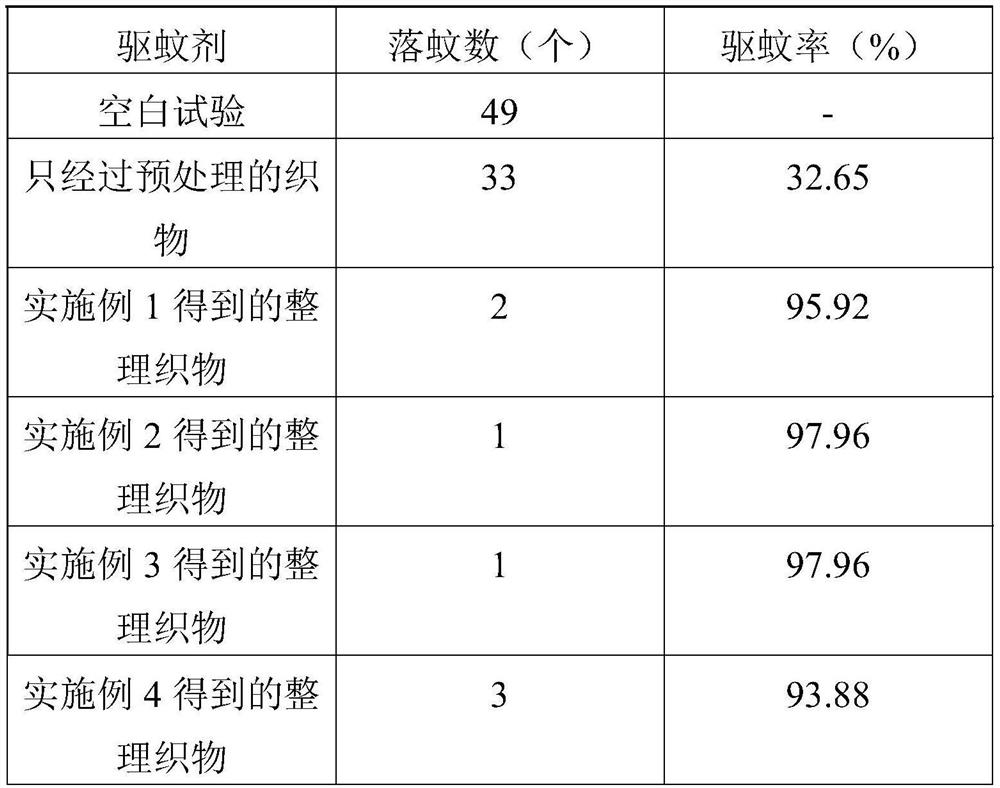

Examples

Embodiment 1

[0051] A mosquito-repellent fabric finishing solution is prepared by mixing mosquito-repellent microcapsule emulsion and auxiliary agents in a mass ratio of 1:5;

[0052] Mosquito repellent microcapsule emulsion is prepared by mixing essential oil microcapsule emulsion and DEET microcapsule emulsion in a mass ratio of 1:1; mixed essential oil microcapsule emulsion is composed of wall material A, wall material B and The core material A is mixed in a mass ratio of 1.5:1:4; the wall material A is a gelatin emulsifier solution with a mass concentration of 1%; the wall material B is a 1% mass concentration of acacia emulsifier solution; the core material A includes mixed plants Essential oil and succinyl anisole, mixed plant essential oil is made by mixing Span-80, Tween-20, lavender essential oil, and citronella essential oil in a mass ratio of 0.8:1:2.5:2.2, and the quality of succinyl anisole is a mixed plant 0.5% of the mass of essential oil; DEET microcapsule emulsion is compo...

Embodiment 2

[0070] A mosquito-repellent fabric finishing solution, the preparation method is the same as that of Example 1, and is prepared by mixing the mosquito-repellent microcapsule emulsion and auxiliary agents in a mass ratio of 1:5; the mosquito-repellent microcapsule emulsion is composed of mixed essential oil microcapsules The emulsion and DEET microcapsule emulsion are mixed according to the mass ratio of 1:0.8;

[0071] The mixed essential oil microcapsule emulsion is formed by mixing wall material A, wall material B and core material A according to a mass ratio of 1:2:3; wall material A is a gelatin emulsifier solution with a mass concentration of 1%; wall material B is a mass Acacia emulsifier solution with a concentration of 1%; core material A includes mixed plant essential oil and butylated hydroxyanisole, and the mixed plant essential oil is made of Span-80, Tween-20, lavender essential oil, and citronella essential oil in a mass ratio of 0.5:2:2.2 :2 mixed, the mass of b...

Embodiment 3

[0075] A mosquito-repellent fabric finishing solution, the preparation method is the same as that of Example 1, and is prepared by mixing the mosquito-repellent microcapsule emulsion and auxiliary agents in a mass ratio of 1:5; the mosquito-repellent microcapsule emulsion is composed of mixed essential oil microcapsules The emulsion and DEET microcapsule emulsion are mixed according to the mass ratio of 1:0.5;

[0076]The mixed essential oil microcapsule emulsion is formed by mixing wall material A, wall material B and core material A according to a mass ratio of 2:1.5:2; wall material A is a gelatin emulsifier solution with a mass concentration of 1%; wall material B is a mass Acacia emulsifier solution with a concentration of 1%; core material A includes mixed plant essential oil and butylated hydroxyanisole, and the mixed plant essential oil is composed of Span-80, Tween-20, lavender essential oil, and citronella essential oil in a mass ratio of 1:1.5:2 : 2.5, the mass of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com