Fabric and preparation method and application thereof

A technology of fabrics and quality parts, applied in the direction of textiles and papermaking, can solve problems such as refractory degradation, environmental impact, and raw materials that are not environmentally friendly, and achieve the effects of convenient operation, high comprehensive performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

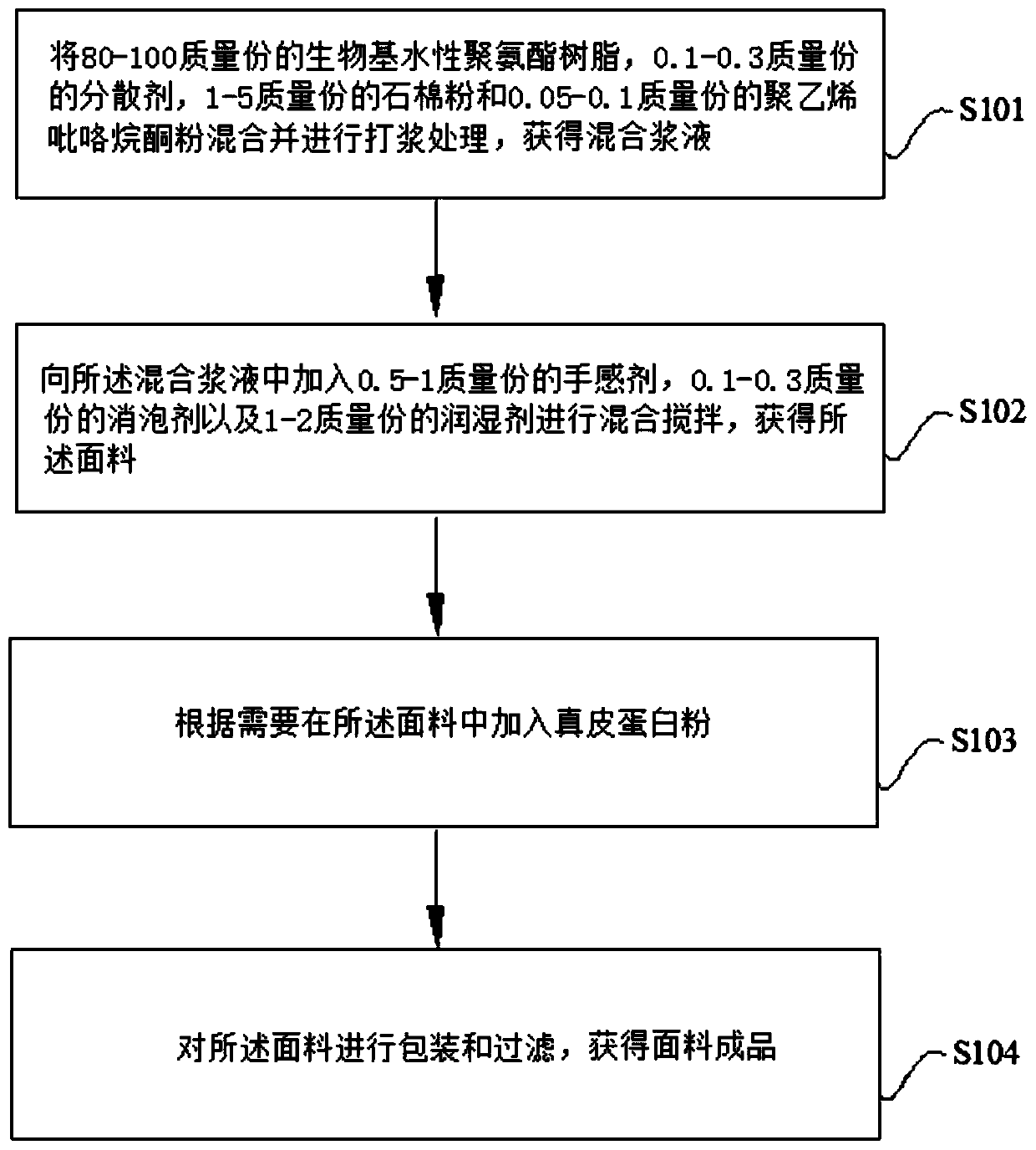

[0019] Such as figure 1 As shown, a preparation method of fabric is provided, at least comprising the following steps:

[0020] S101, mixing 80-100 parts by mass of bio-based water-based polyurethane resin, 0.1-0.3 parts by mass of dispersant, 1-5 parts by mass of asbestos powder and 0.05-0.1 parts by mass of polyvinylpyrrolidone powder and performing beating treatment to obtain Mixing slurry; the step of performing beating treatment includes: performing beating treatment at a rotational speed of 800-1200 rpm. The dispersant includes one or more combinations of sodium salt, ammonium salt or high molecular polymer.

[0021] S102. Add 0.5-1 mass parts of hand feeling agent, 0.1-0.3 mass parts of defoaming agent and 1-2 mass parts of wetting agent to the mixed slurry for mixing and stirring to obtain the fabric.

[0022] S103. Add leather protein powder to the fabric as required. The step of adding the dermis protein powder comprises: preparing the dermis protein powder into a...

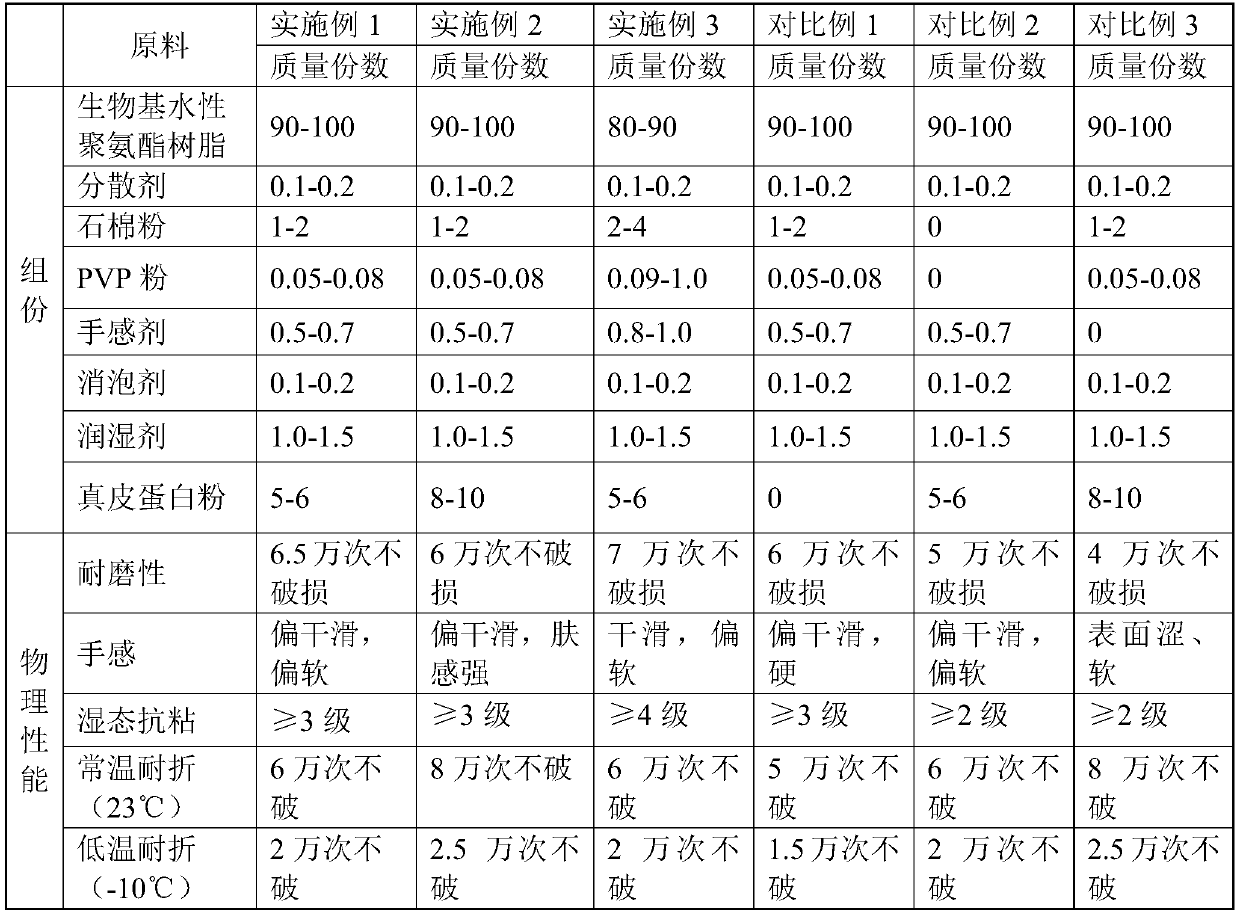

Embodiment 1

[0027] Take 90-100 parts by mass of bio-based water-based polyurethane resin and place it in a reaction vessel, add 0.1-0.2 parts by mass of dispersant to the reaction vessel under stirring for 5-10 minutes, then add 1-2 parts by mass of Asbestos powder and 0.05-0.08 parts by mass of polyvinylpyrrolidone powder, that is, PVP powder, are dispersed for 20-30 minutes at a speed of 800-1200 rpm, and then added with 0.5-0.7 parts by mass of hand feeling agent and 0.1 parts by mass while stirring. 0.2 parts by mass of defoaming agent, 1.0-1.5 parts by mass of wetting agent and 5-6 parts by mass of dermis protein powder, after dispersing for 15-20 minutes, fabric A is obtained. Dermis protein powder is added to this example.

Embodiment 2

[0029] Take 90-100 parts by mass of bio-based water-based polyurethane resin and place it in a reaction vessel, add 0.1-0.2 parts by mass of dispersant to the reaction vessel under stirring for 5-10 minutes, then add 1-2 parts by mass of Asbestos powder and 0.05-0.08 parts by mass of polyvinylpyrrolidone powder, that is, PVP powder, are dispersed for 20-30 minutes at a speed of 800-1200 rpm, and then added with 0.5-0.7 parts by mass of hand feeling agent and 0.1 parts by mass while stirring. 0.2 parts by mass of defoaming agent, 1.0-1.5 parts by mass of wetting agent and 8-10 parts by mass of dermis protein powder are dispersed for 15-20 minutes to obtain fabric B. In this embodiment, different amounts of dermis protein powder are added from other embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com