Box girder construction method through using multiple hold hoops and trusses for supporting Bailey truss based on large-span box girder

A box girder construction, long-span technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult to meet the span, few supporting nodes, difficult construction, etc., and achieve significant economic and social benefits and safety. High, easy and fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

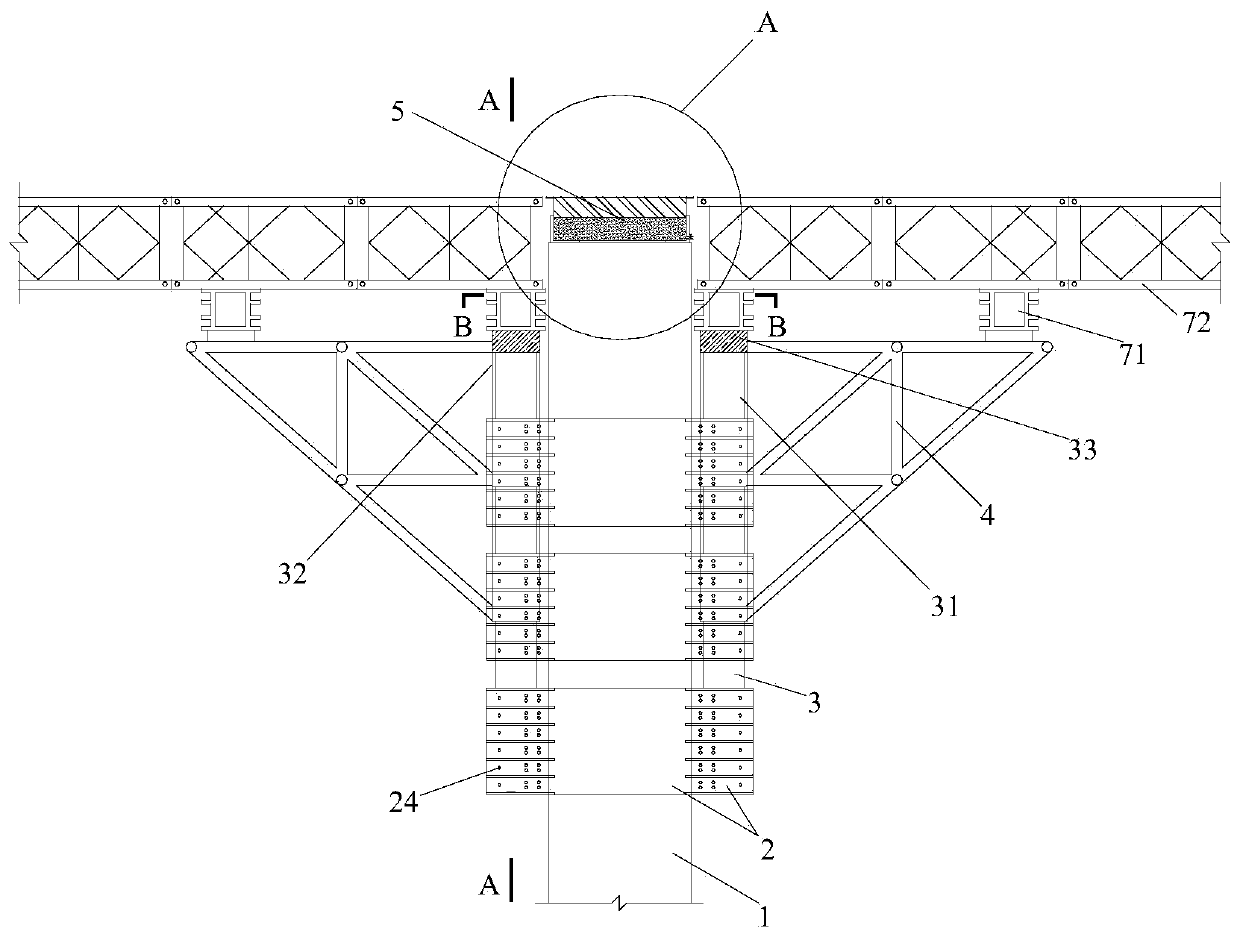

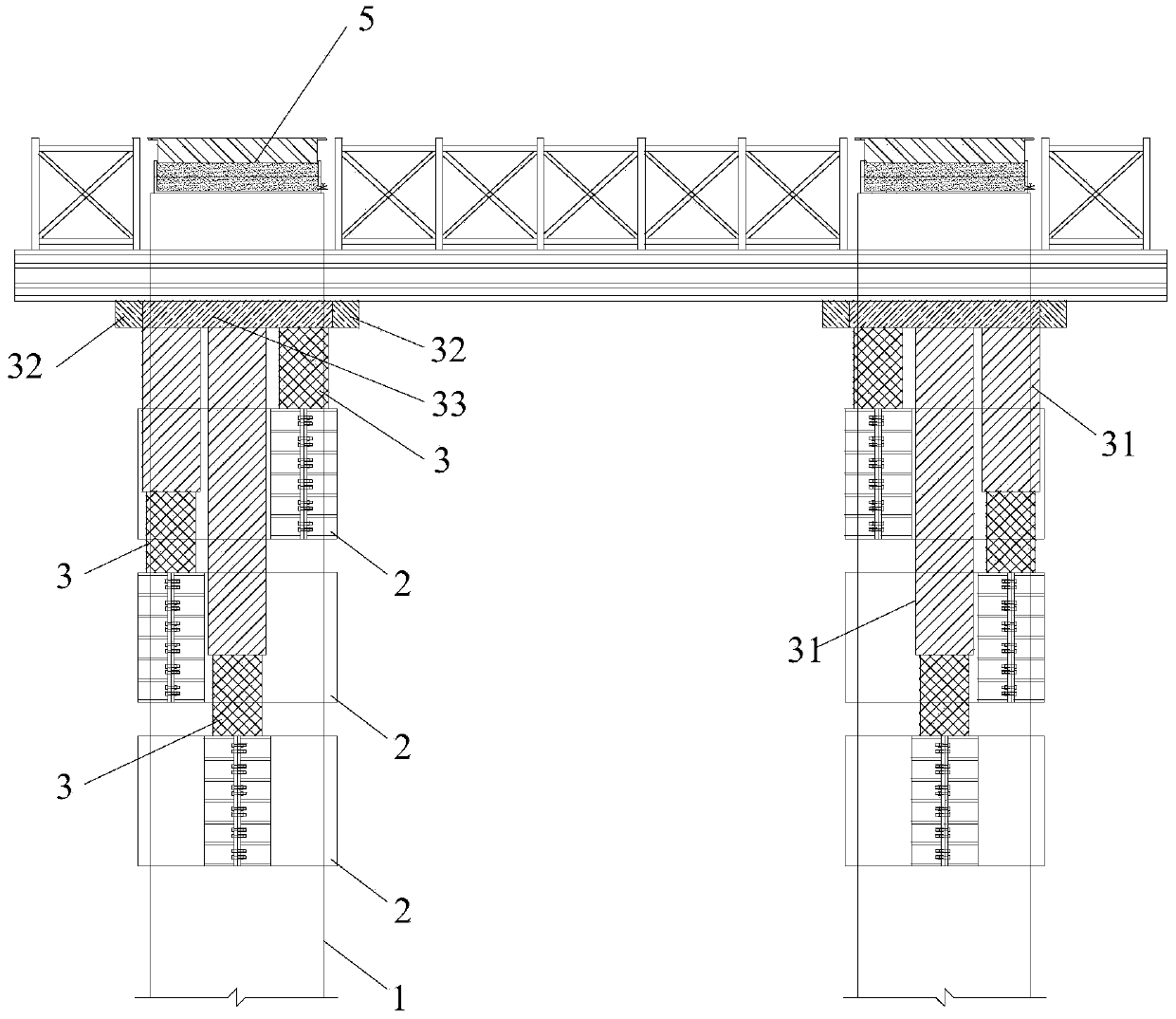

[0041] In order to deepen understanding of the present invention, reference will be made below to the attached figure 1 ~ attached Figure 12 , the embodiments of the present invention are described in detail, the following embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0042] The present invention relates to a box girder construction method based on a large-span box girder multi-clamp truss supporting a Bailey bracket, comprising the following steps:

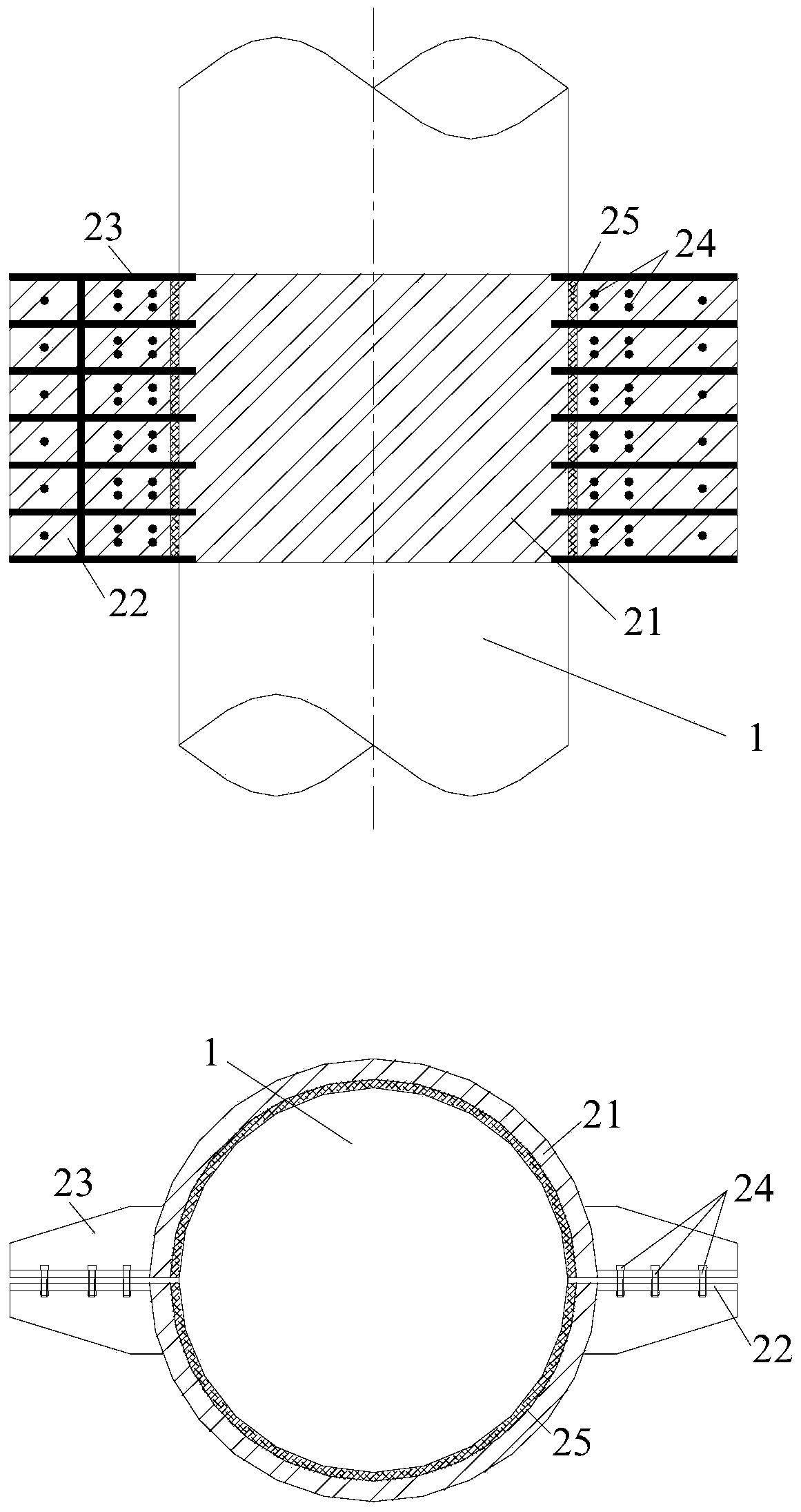

[0043] 1) A number of hoops 2 are installed on each pier column 1, and hoop webs 22 are arranged on the hoops 2, combined with the attached image 3 As shown, the hoop 2 is spliced by two holding plates 21. The holding plate 21 adopts a flexible plate body without annular stiffeners. The diameter of the inner circle of the holding hoop 2 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com