A steel structure channel steel connecting member

A technology for connecting components and steel structures, used in building structures, buildings, etc., can solve the problems of small application scope, troublesome disassembly of steel structure profiles, and profile damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

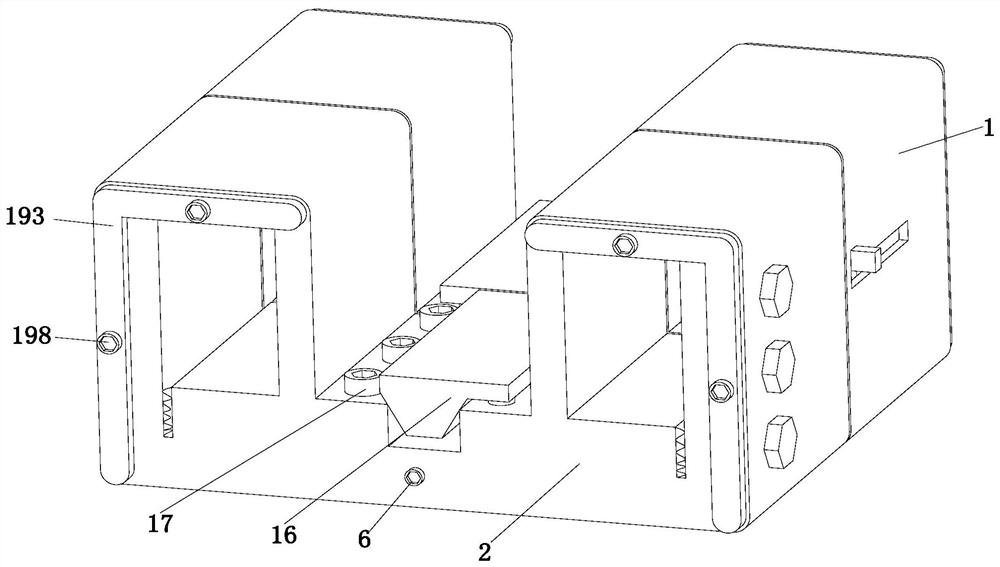

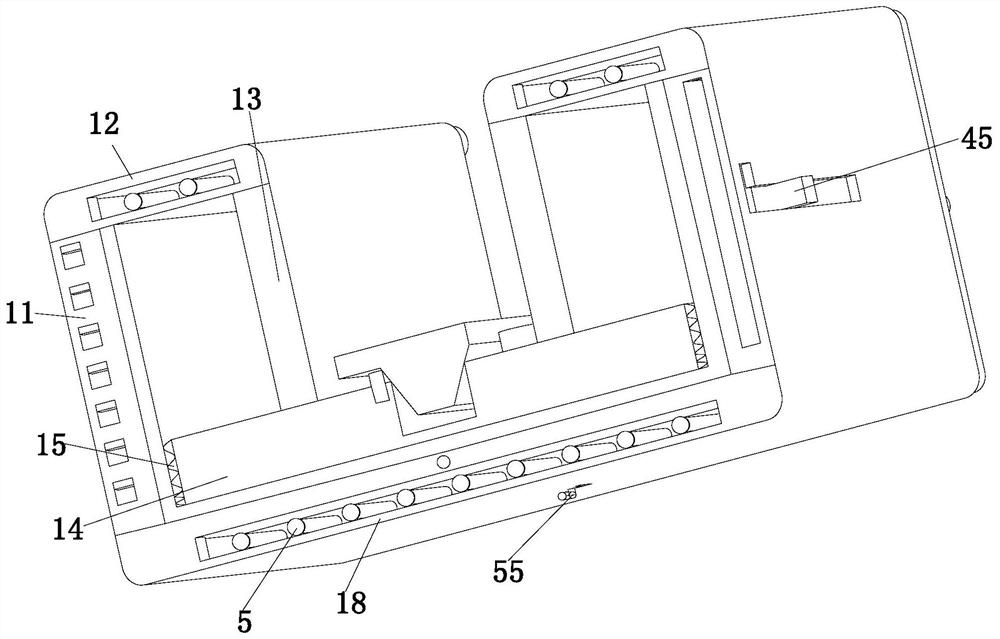

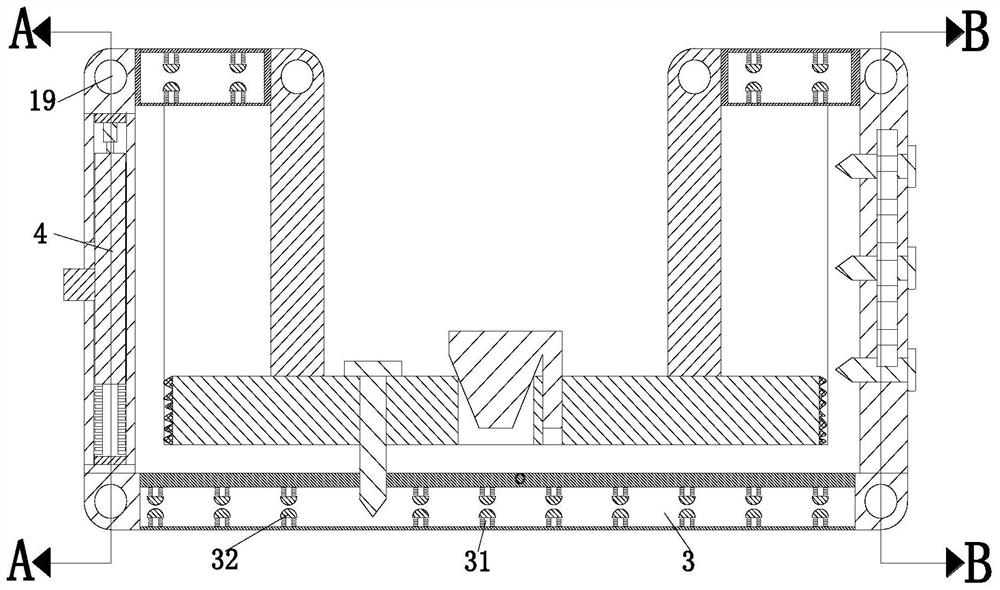

[0031] like Figure 1 to Figure 7 As shown, a steel structure channel steel connecting member includes a No. 1 butt joint device 1 and a No. 2 butt joint device 2. The No. 1 butt joint device 1 and No. 2 butt joint device 2 are connected by a retaining threaded straight rod 6. A push rod mechanism 5 is installed on the front side of the lower end of the docking device 1, and a clamping mechanism 3 is installed on the rear side of the lower end of the No. 2 docking device 2. The No. 1 docking device 1 and the No. 2 docking device 2 have the same structure.

[0032] The No. 1 docking device 1 includes a straight plate 11, a connecting plate 12, a rotating plate 13, a pressing plate 14, a rubber pad 15, a fastening nail 16, a locking nut 17 and a base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com