Bent beam skeleton membrane structure environment-friendly silo

A technology of membrane structures and curved beams, which is applied in special structures, arched structures, dome structures, etc., can solve problems such as difficulty in supervision, lack of ventilation, and many dead ends of rods, so as to reduce the amount just now and facilitate the installation of membrane materials , the effect that the height of the cross-section is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

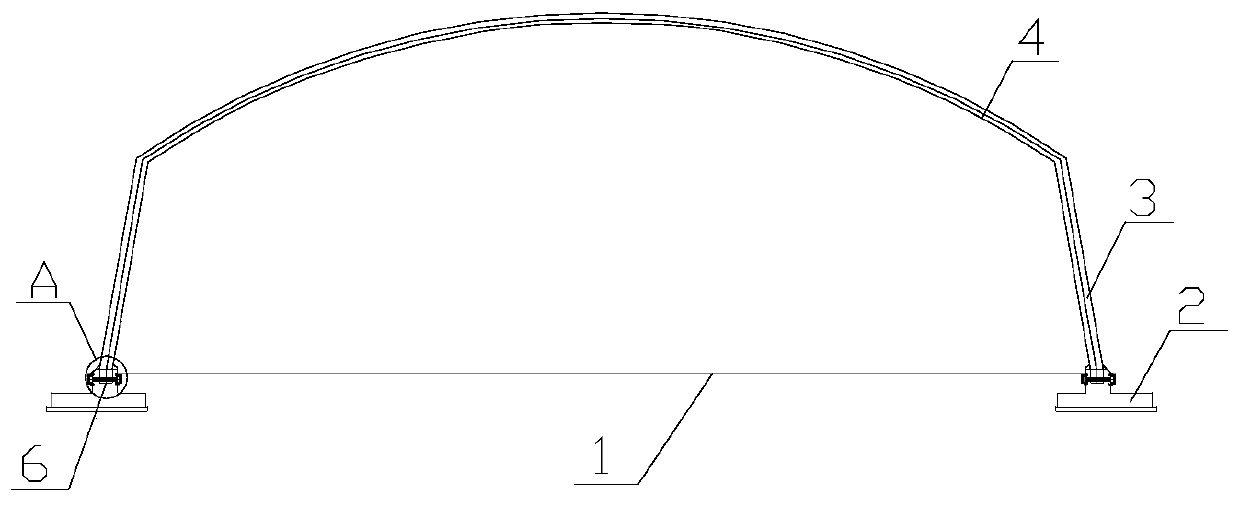

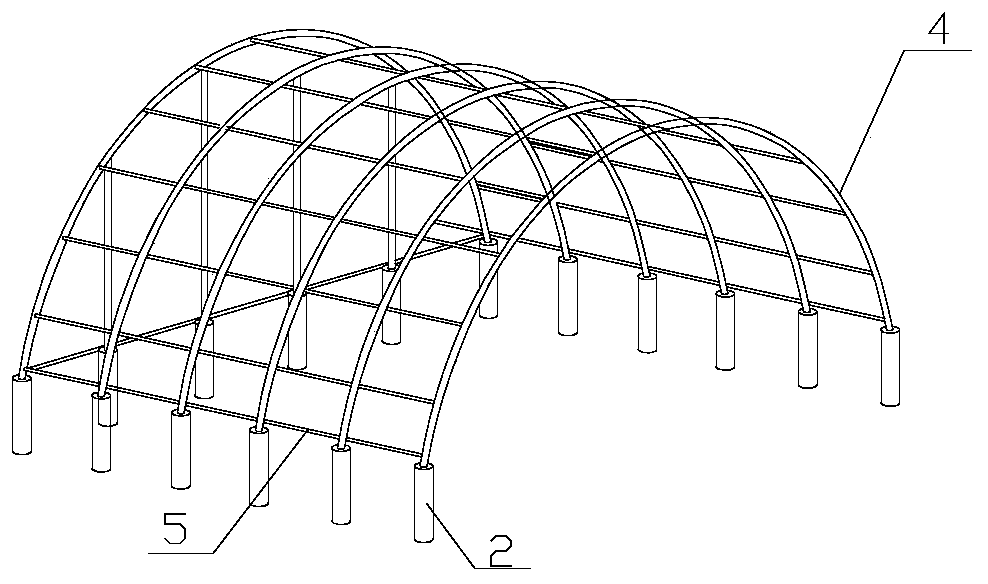

[0026] see figure 1 , figure 2 , Figure 4 and Figure 5 , the present invention provides an environmentally friendly silo with a curved beam skeleton membrane structure: including ground 1, reinforced concrete foundation support 2, straight H-shaped steel 3, curved H-shaped steel 4, and connecting structure 6, and reinforced concrete foundation support 2 is embedded at equal intervals More than two are on the top of the ground 1, the straight H-shaped steel 3 is fixedly connected to the top of the reinforced concrete foundation support 2 through the connecting structure 6, and the left and right sides of the bottom end surface of the curved H-shaped steel 4 are respectively locked to the tops of two symmetrical straight H-shaped steel 3 On the surface, the curved H-shaped steel 4 is composed of a web 41, an upper flange plate 42 and a lower flange plate 43, and the top end surface and the bottom end surface of the web plate 41 are an integrated structure, and an upper flan...

Embodiment 2

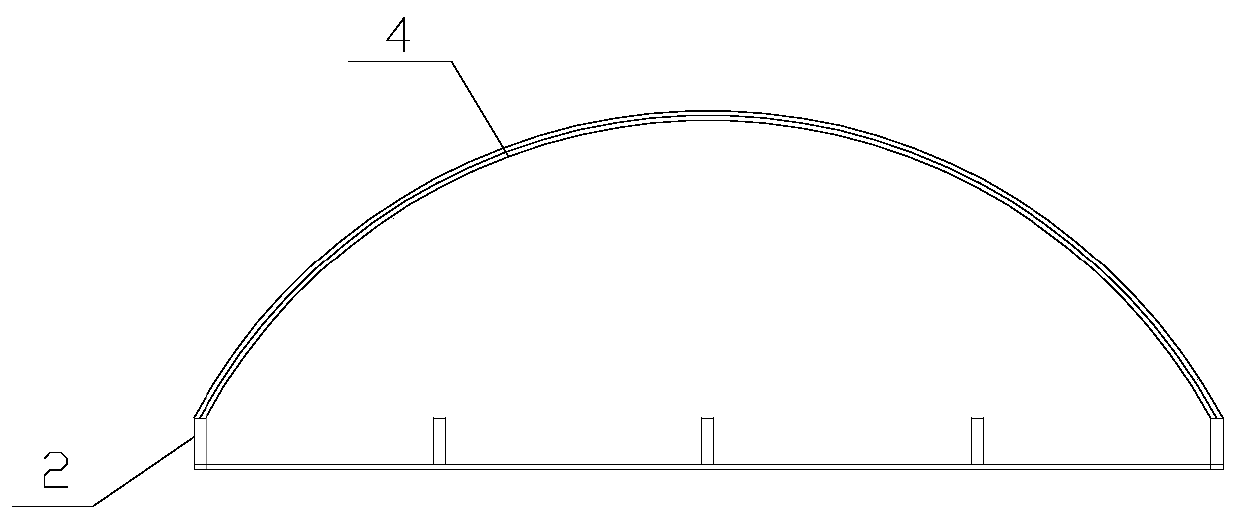

[0037] see figure 2 , image 3 and Figure 4 , the present invention provides an environmentally friendly silo with a curved beam skeleton membrane structure: it includes a reinforced concrete foundation support 2, a curved H-shaped steel 4 and a strut 5, and the left and right sides of the bottom end surface of the curved H-shaped steel 4 are respectively locked on two left and right symmetrical The top surface of the reinforced concrete foundation support 2, the strut 5 is locked to the inner end surface of the curved H-shaped steel 4, the curved H-shaped steel 4 is composed of a web 41, an upper flange plate 42 and a lower flange plate 43, the top surface of the web 41 and The bottom end surface is an integrated structure with an upper flange plate 42 and a lower flange plate 43 respectively, and the front and rear end surfaces of the upper flange plate 42 and the lower flange plate 43 are parallel to the front and rear end surfaces of the web 41.

[0038] Wherein embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com