Lifting cross arm for hot-line work and application method of lifting cross arm

A live work, cross arm technology, applied in overhead lines/cable equipment, towers, building types, etc., can solve the problems of small operating space and complicated wiring of poles, reduce work intensity, eliminate insufficient operating space, use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

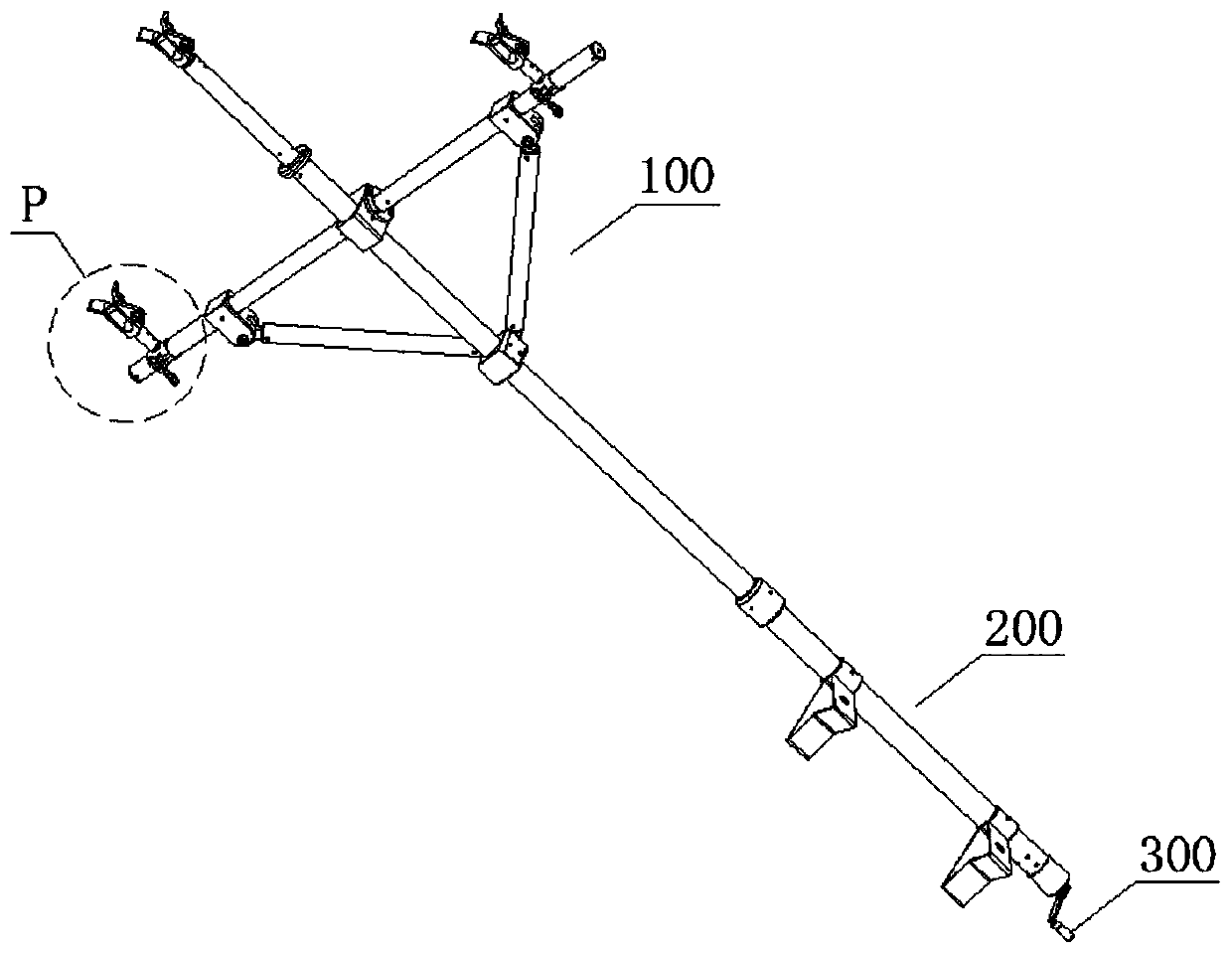

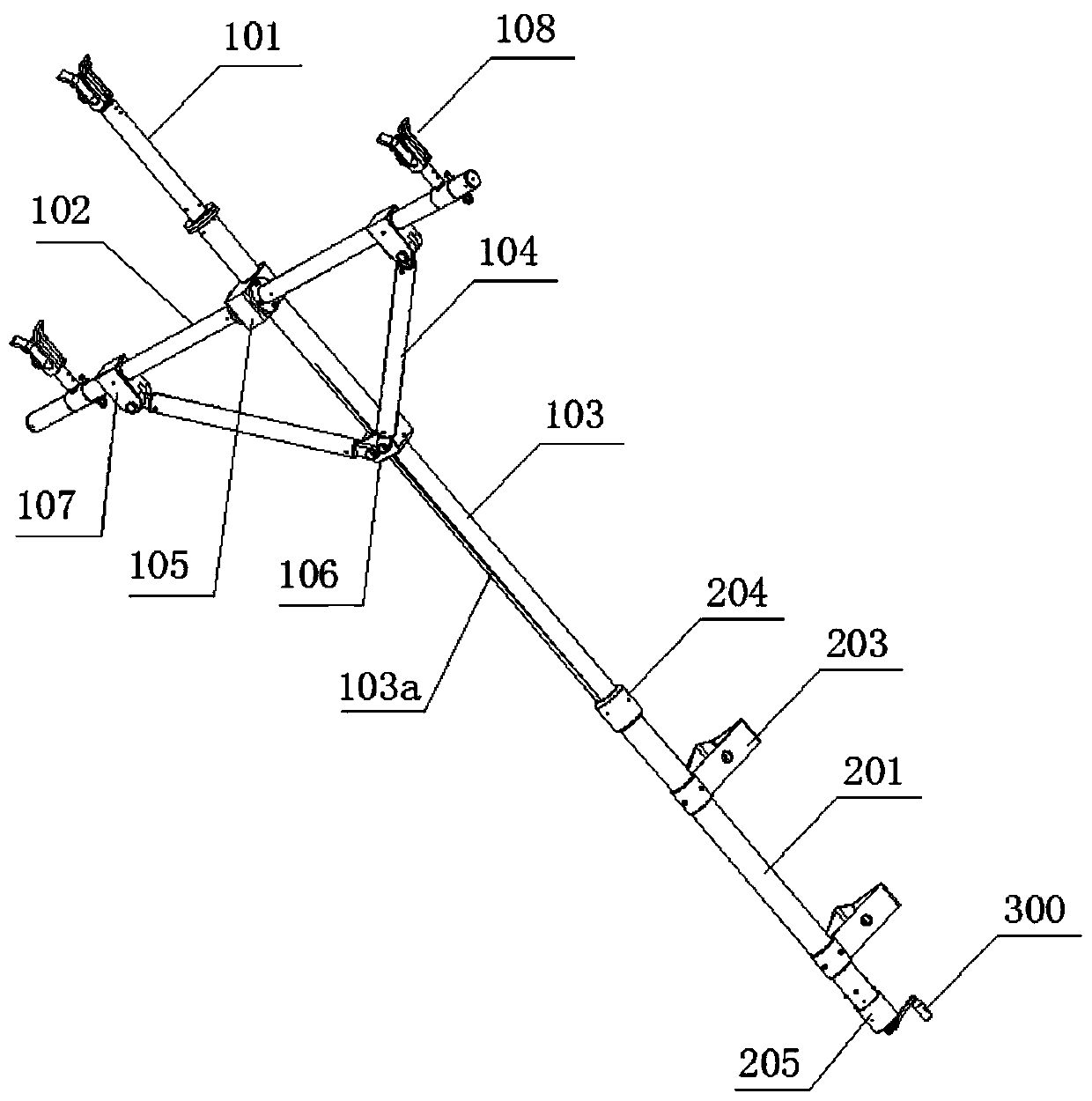

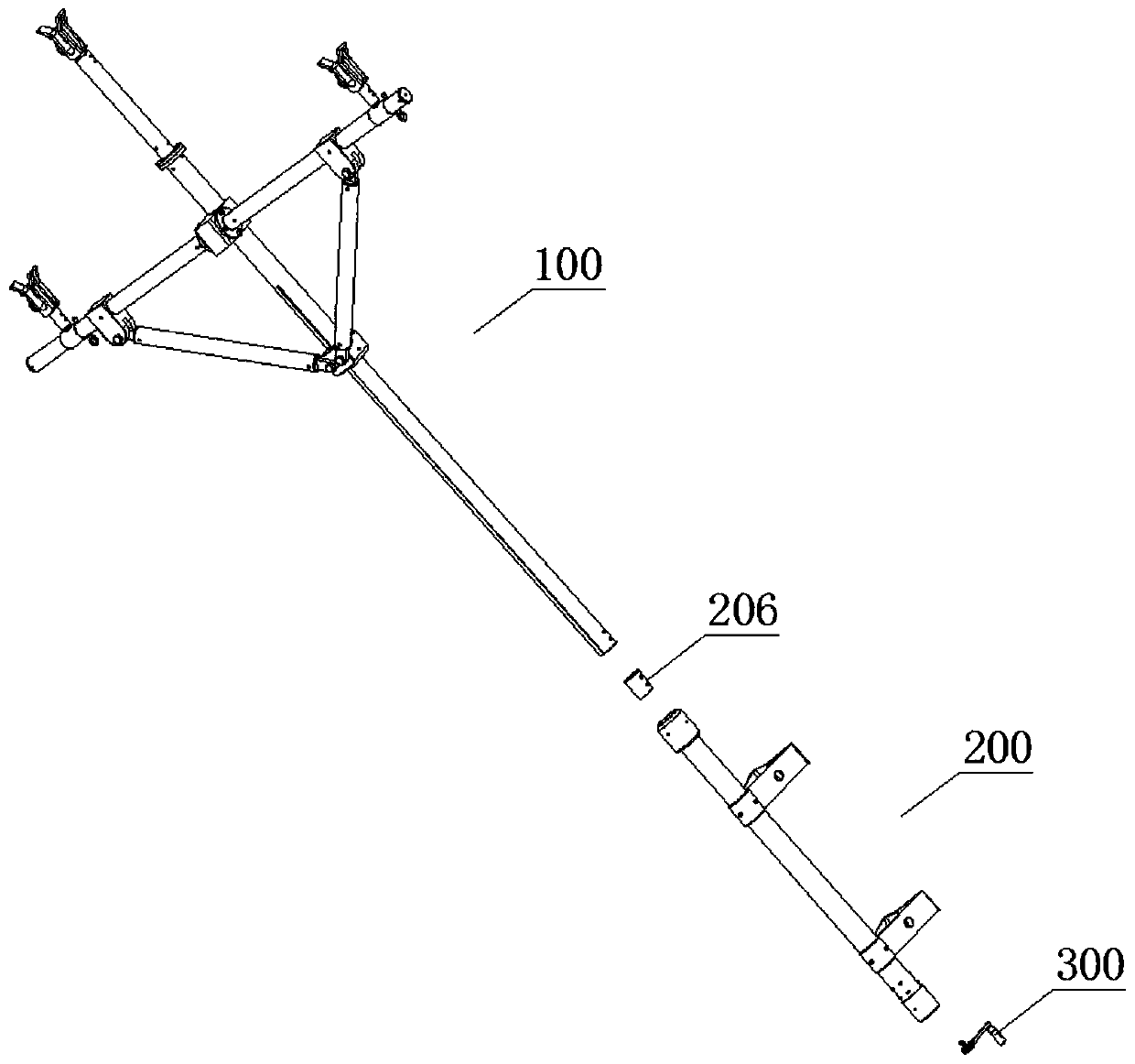

[0063] refer to Figure 1 to Figure 3 As shown, a lifting cross arm for live work provided by the present invention includes a liftable cross arm main body 100, a cross arm base 200 and a quick-plug torque handle 300, and the liftable cross arm main body 100 is arranged on the cross arm base At one end of 200, the quick plug-in torque handle 300 is arranged on the other end of the cross arm base 200; wherein, the liftable cross arm main body 100 is used to place wires and adjust the interphase spacing of wires during the replacement of insulators to prevent wires from falling off, Leakage, short circuit, etc.; the quick plug-in torque handle 300 is used to adjust and control the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com