Hollow grouting anchor rod with conical expansion head and construction method

A technology of grouting bolts and expanding heads, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., which can solve the problems of reduced construction efficiency, displacement, and falling of hollow bolts, and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

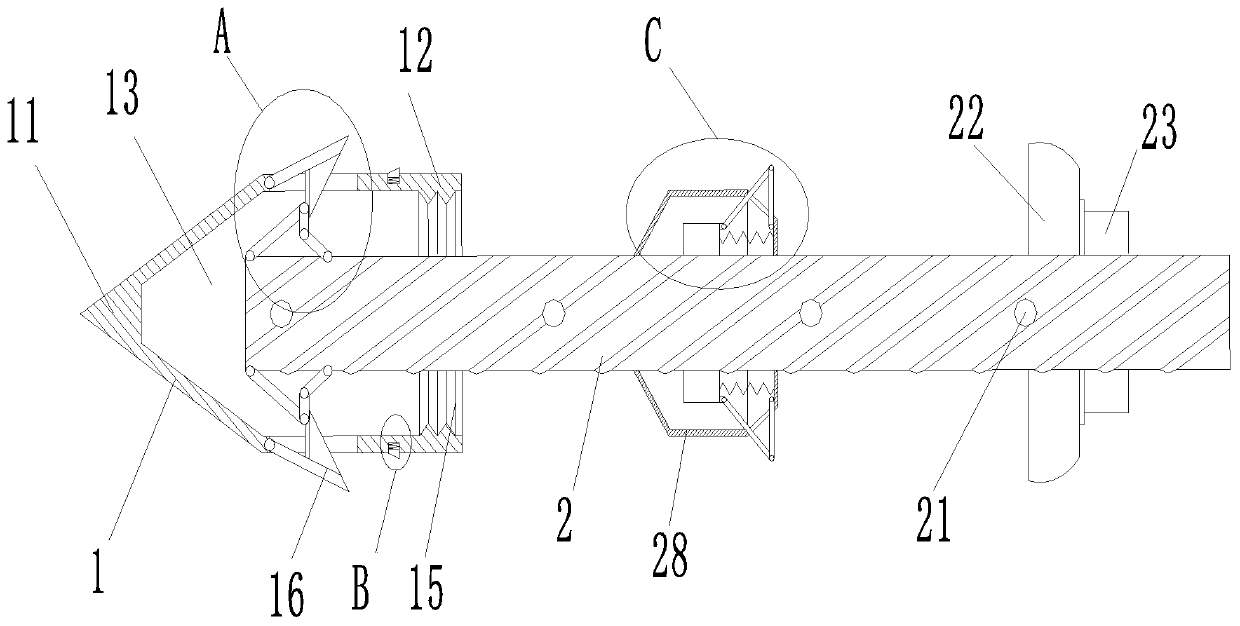

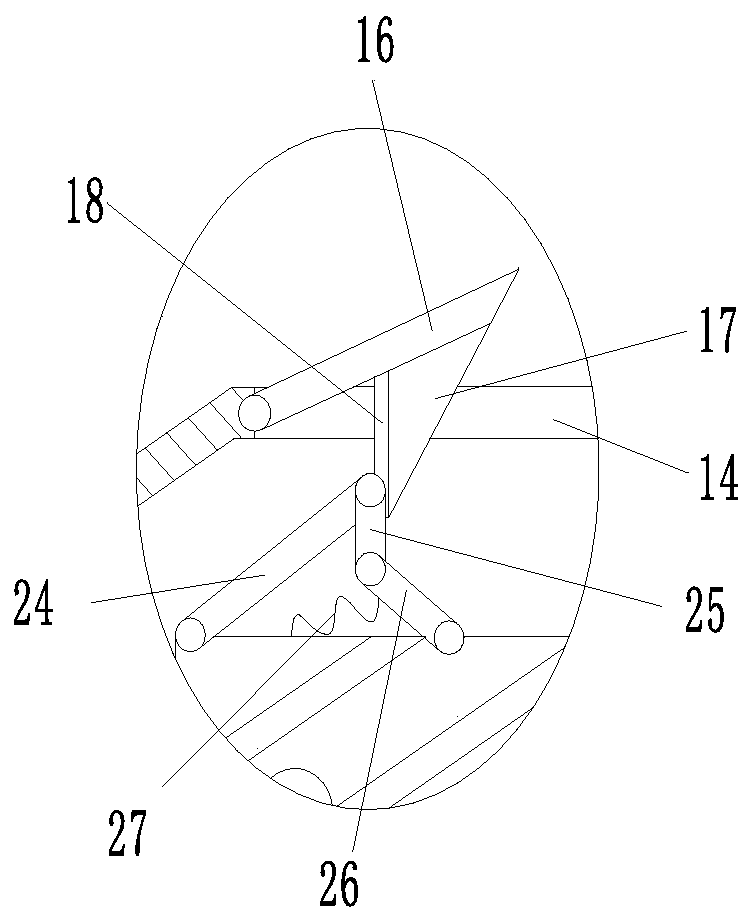

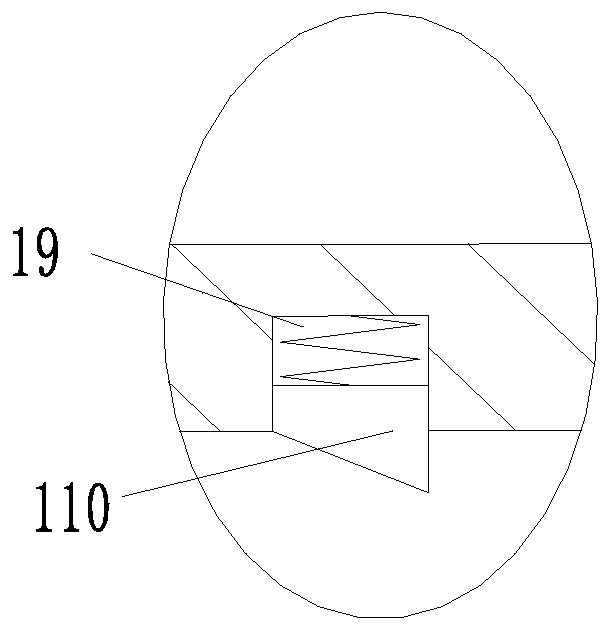

[0026] like Figure 1 to Figure 4 As shown, a hollow grouting anchor 2 with a conical enlarged head includes a conical fixing part 1 and a hollow grouting anchor 2. 11 and cylindrical portion 12, the tapered portion 11 and the cylindrical portion 12 are provided with a cavity 13, the cylindrical portion 12 is provided with a first mounting groove 14 on the side wall and an internal thread 15 at the end , the first installation groove 14 is rotatably connected with the first stopper 16, and the hollow grouting anchor rod 2 is provided with several overflow holes 21, and the grouting function will be realized by utilizing the overflow holes 21. The front end of the hollow grouting anchor 2 is provided with a limit structure, the limit structure extends into the cavity 13 and matches with the first limiter 16, the hollow grouting anchor 2 is provided with an anchoring structure, the hollow grouting anchor 2 An anchor tray 22 and a locking member 23 are threadedly connected to th...

Embodiment 2

[0033] A construction method of a hollow grouting anchor with a conical enlarged head, comprising the following steps,

[0034] Step 1. Fix the drill rod and the internal thread 15 of the cylindrical part 12 of the tapered fixing part 1, drill out the bolt installation hole, and then take out the drill bit and leave the tapered fixing part 1 in the installation hole;

[0035] Step 2. Use high-pressure air to clear the hole, and do not use clean water to rinse;

[0036] Step 3: Insert one end of the hollow grouting anchor 2 with a limiting structure into the anchor installation hole until the second connecting rod 25 completely passes through the triangular limiter 17, and connect the hollow grouting anchor 2 to the anchor tray 22 and locking member 23;

[0037] Step 4: Adjust the locking member 23 and the anchor tray 22, pull out the hollow grouting anchor rod 2, drive the second connecting rod 25 in the limiting structure to squeeze the positioning groove 18 of the first lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com