Corrosion-resistant pressure transmitter equipment

A transmitter and corrosion-resistant technology, applied in the field of corrosion-resistant pressure transmitter equipment, can solve problems such as damage to the circuit board of the pressure transmitter, and achieve the effects of avoiding electromagnetic interference, reasonable structure design, and improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

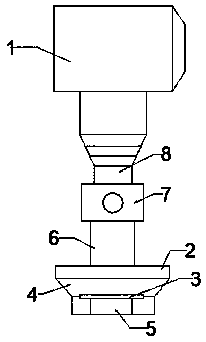

[0019] As a preferred embodiment of the present invention, a transition ring 4 is provided under the flange base 2, and the flange base 2 and the transition ring 4 are connected by argon arc welding.

[0020] As a preferred embodiment of the present invention, the outer diameter of the isolation diaphragm 3 is 35-66 mm, and the effective diameter of the isolation diaphragm 3 is 25-60 mm.

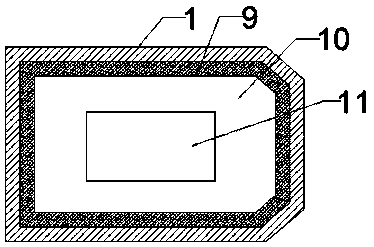

[0021] As a preferred embodiment of the present invention, the circuit board 10 is fixed inside the insulating sheath 9 , and the inside of the insulating sheath 9 is filled with a sealing layer 10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com