Flow table system for air flow debugging of gas turbine

A technology of air flow and gas turbine, applied in the direction of gas turbine engine testing, jet engine testing, engine testing, etc., can solve problems such as unsatisfactory engine requirements, improve test accuracy and test efficiency, improve recording efficiency, and improve intelligence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

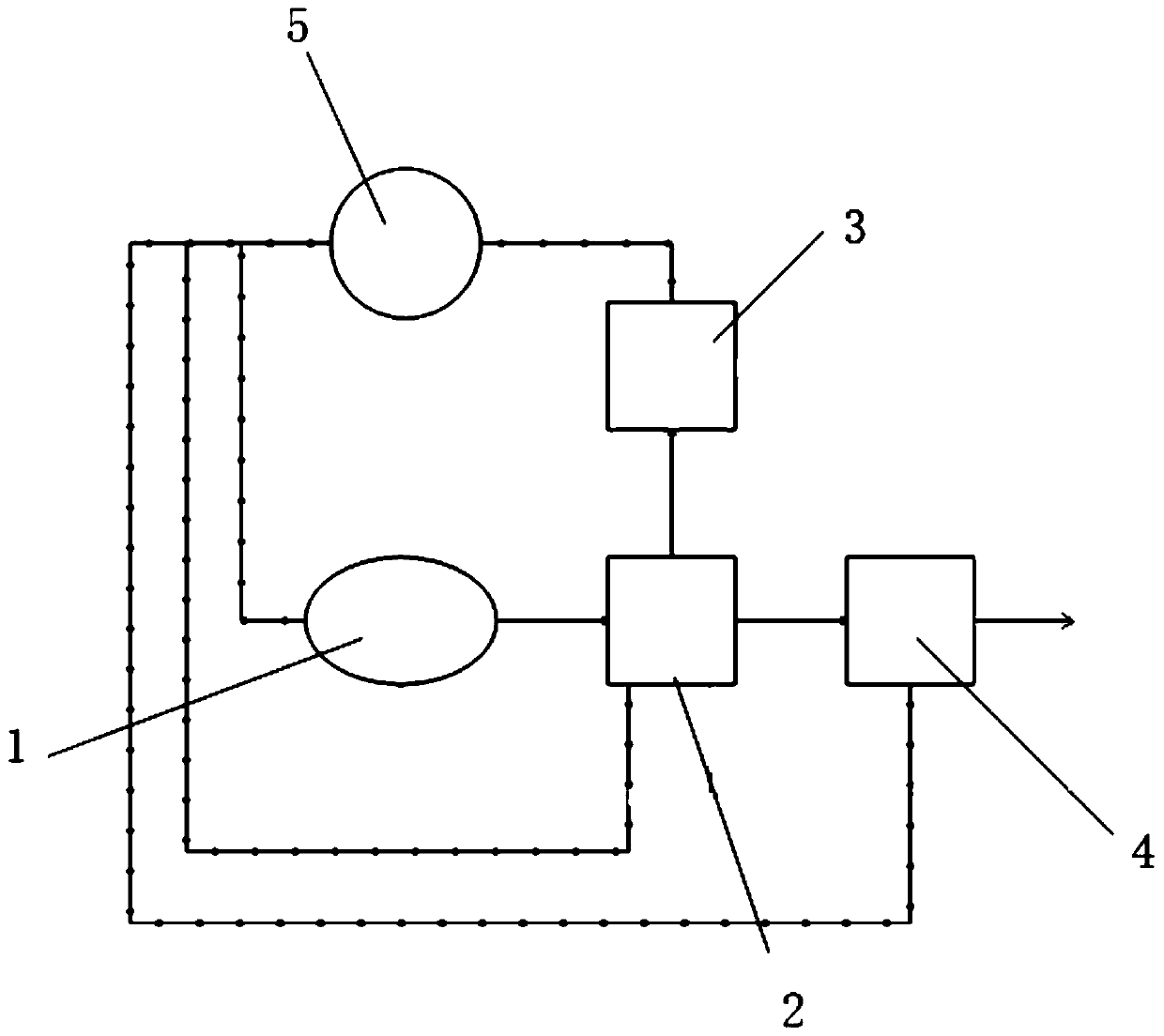

[0050] Such as figure 1 , figure 2 and image 3 as shown,

[0051] A flow table system for gas turbine air flow debugging, comprising a gas station mechanism 1, a pressure control mechanism 2, a temperature measurement mechanism 3, an air flow measurement mechanism 4 and a computer measurement and control mechanism 5, the output end of the gas station mechanism 1 is connected to the The input end of the pressure control mechanism 2 is connected, the output end of the pressure control mechanism 2 is connected with the input end of the temperature measurement mechanism 3, and the output end of the pressure control mechanism 2 is also connected with the input end of the air flow measurement mechanism 4, so The output ends of the pressure control mechanism 2, the temperature measurement mechanism 3 and the air flow measurement mechanism 4 are all connected to the recovery end of the gas station mechanism 1, and the gas station mechanism 1, the pressure control mechanism 2, the ...

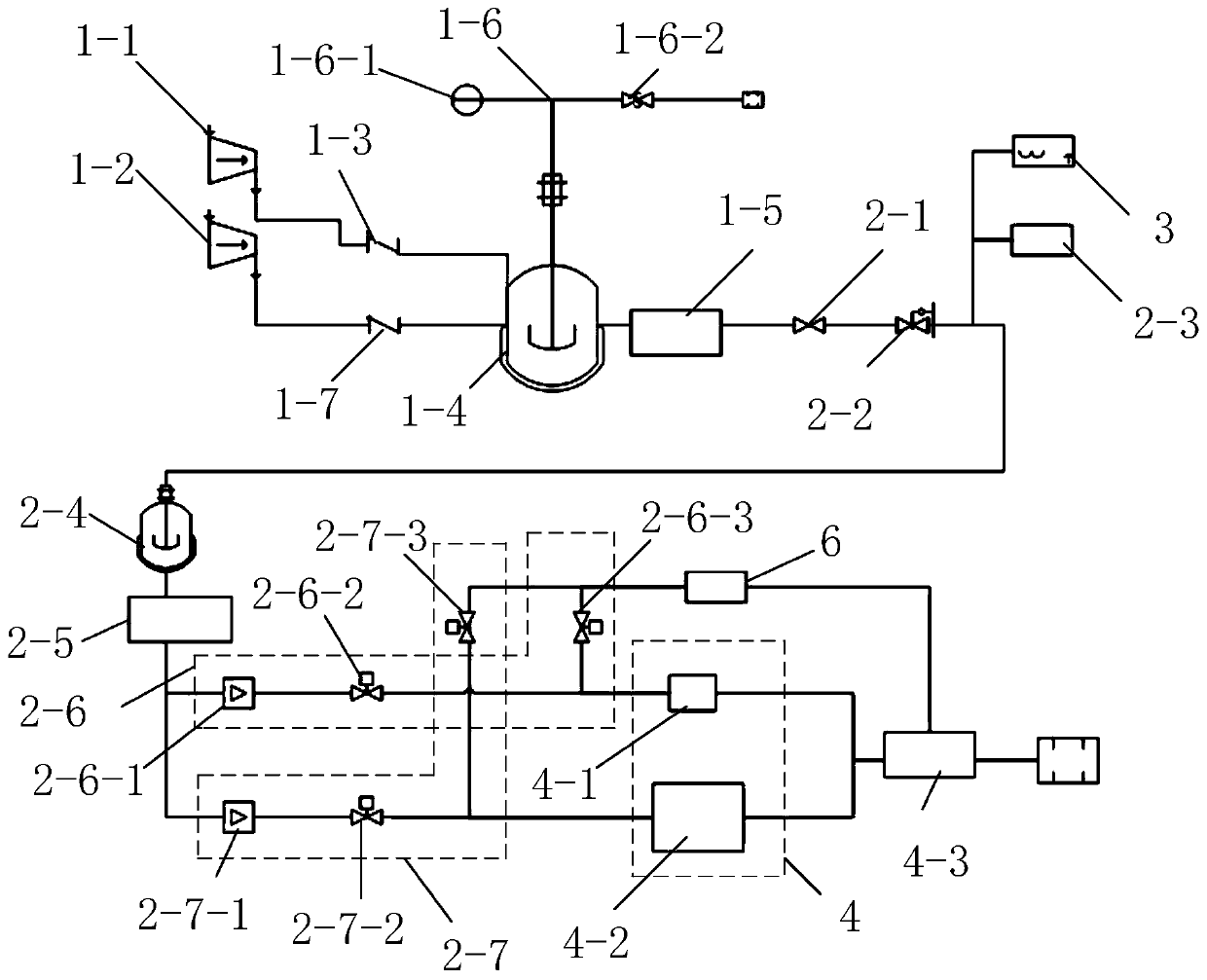

Embodiment 1

[0053] According to the above-mentioned embodiment, the gas station mechanism is further limited. The gas station mechanism 1 includes a low-pressure compressor 1-1, a high-pressure compressor 1-2, a first one-way valve 1-3, a second one-way valve 1-7. The gas storage tank 1-4 and the crude air filter 1-5 are composed. The low-pressure air compressor 1-1 is connected to the air storage tank 1-4 through the first one-way valve 1-3. The high-pressure air compressor The machine 1-2 is connected to the air storage tank 1-4 through the second one-way valve 1-7, and the output end of the air storage tank 1-4 is connected with the input end of the crude air filter 1-5, and the crude air The output terminals of the consideration 1-5 are connected with the input terminals of the pressure control mechanism 2.

[0054] The above-mentioned coarse air filter refers to a filter with a larger particle size of suspended solids that can be filtered.

[0055] In the first embodiment above, the...

Embodiment 2

[0058] According to the above embodiment, the pressure control mechanism is further limited. The pressure control mechanism 2 is composed of a pneumatic shut-off valve 2-1, a pressure reducing valve 2-2, a pressure sensor 2-3, a stabilized pressure gas storage tank 2-4, The precision air filter 2-5, the first pressure control device 2-6 and the second pressure control device 2-7 are composed, the input end of the pneumatic stop valve 2-1 is connected with the output end of the gas station mechanism 1, and the The output end of the pneumatic shut-off valve 2-1 is connected to the input end of the pressure reducing valve 2-2, and the output end of the pressure reducing valve 2-2 is connected to the input end of the pressure-stabilizing gas storage tank 2-4, and the pressure-stabilizing valve The output end of the pressure storage tank 2-4 is connected to the input end of the precision air filter 2-5, and the output end of the precision air filter 2-5 is connected to the input end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com