Electroplating power supply circuit for realizing stable output of any waveform

A power supply circuit and stable output technology, which is applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve the problems that the electroplating power supply cannot meet the production requirements of multi-stage frequency conversion corrosion process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

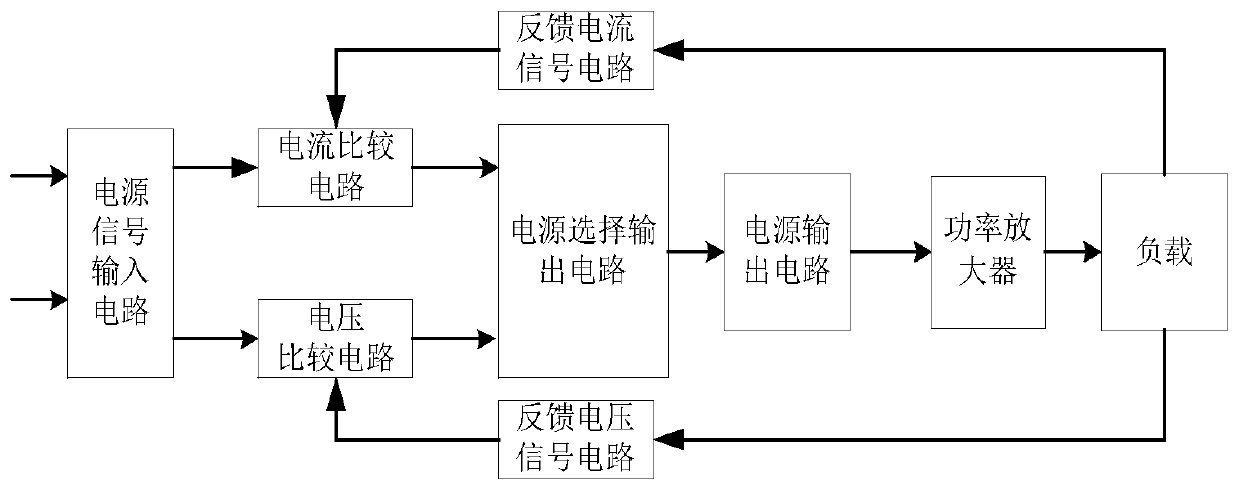

[0163] Such as figure 1 As shown, an electroplating power supply circuit that realizes stable output of arbitrary waveforms includes a power signal input circuit, a feedback current signal circuit, a current comparison circuit, a power supply circuit, and a power amplifier; a feedback voltage signal circuit, a voltage comparison circuit, a power output circuit, and a power supply Select the output circuit;

[0164] The power signal input circuit is used to input a voltage signal or a current signal, and perform multi-stage 1:1 amplification processing on the current signal or voltage signal, and then input the input current signal to the current comparison circuit, and input the input voltage signal to the voltage comparison circuit;

[0165] The feedback current signal circuit is used to input the current signal fed back by the load, and after performing multi-stage operation and amplification processing on the input load feedback current signal, it is input into the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com