Cleaning and laminating all-in-one machine for ceramic disc and wafer

An all-in-one, ceramic disk technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high labor consumption, unstable quality, and high technical requirements of workers, to meet modern high-speed production and reduce manual labor. Intensity, the effect of guaranteeing the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

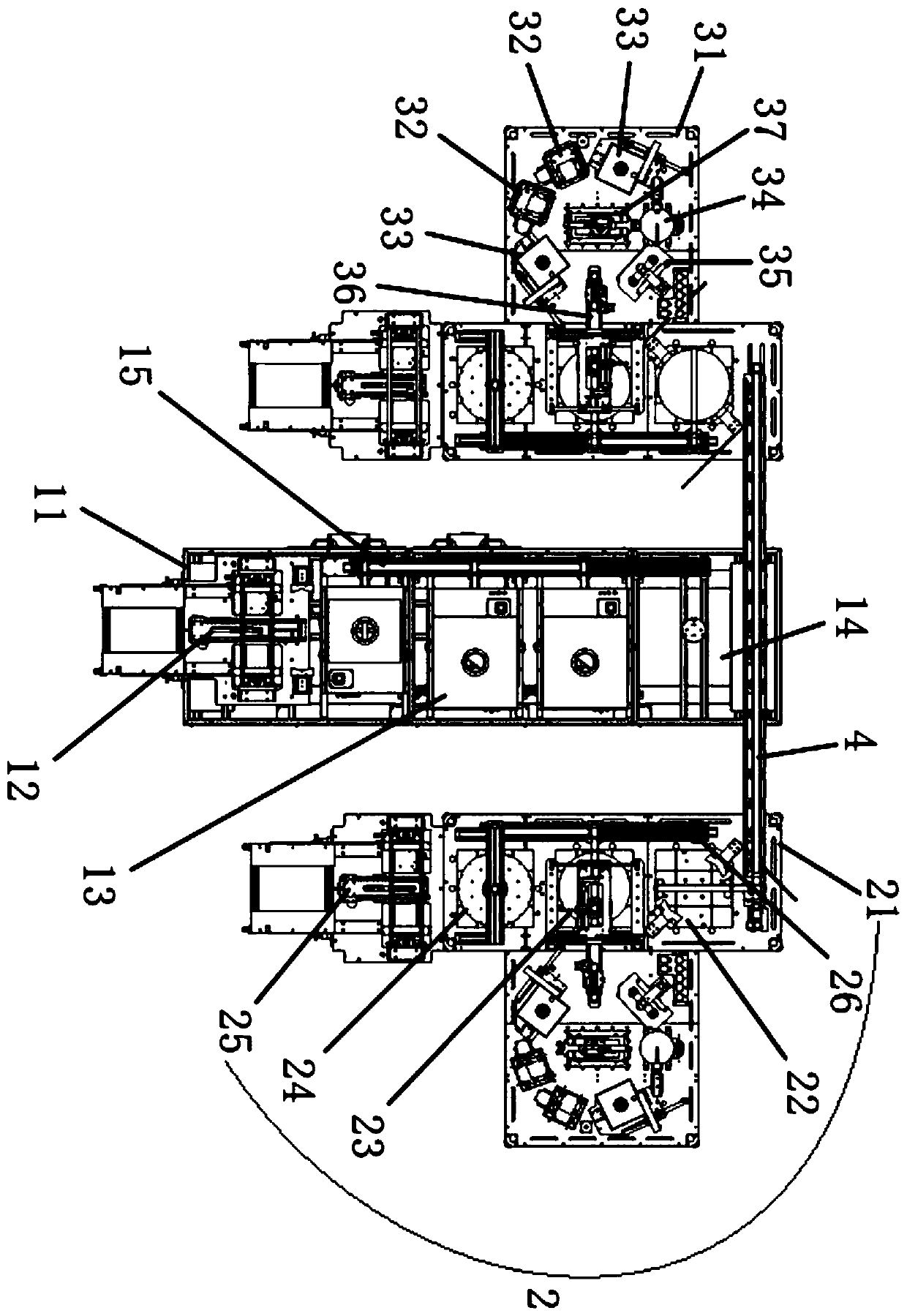

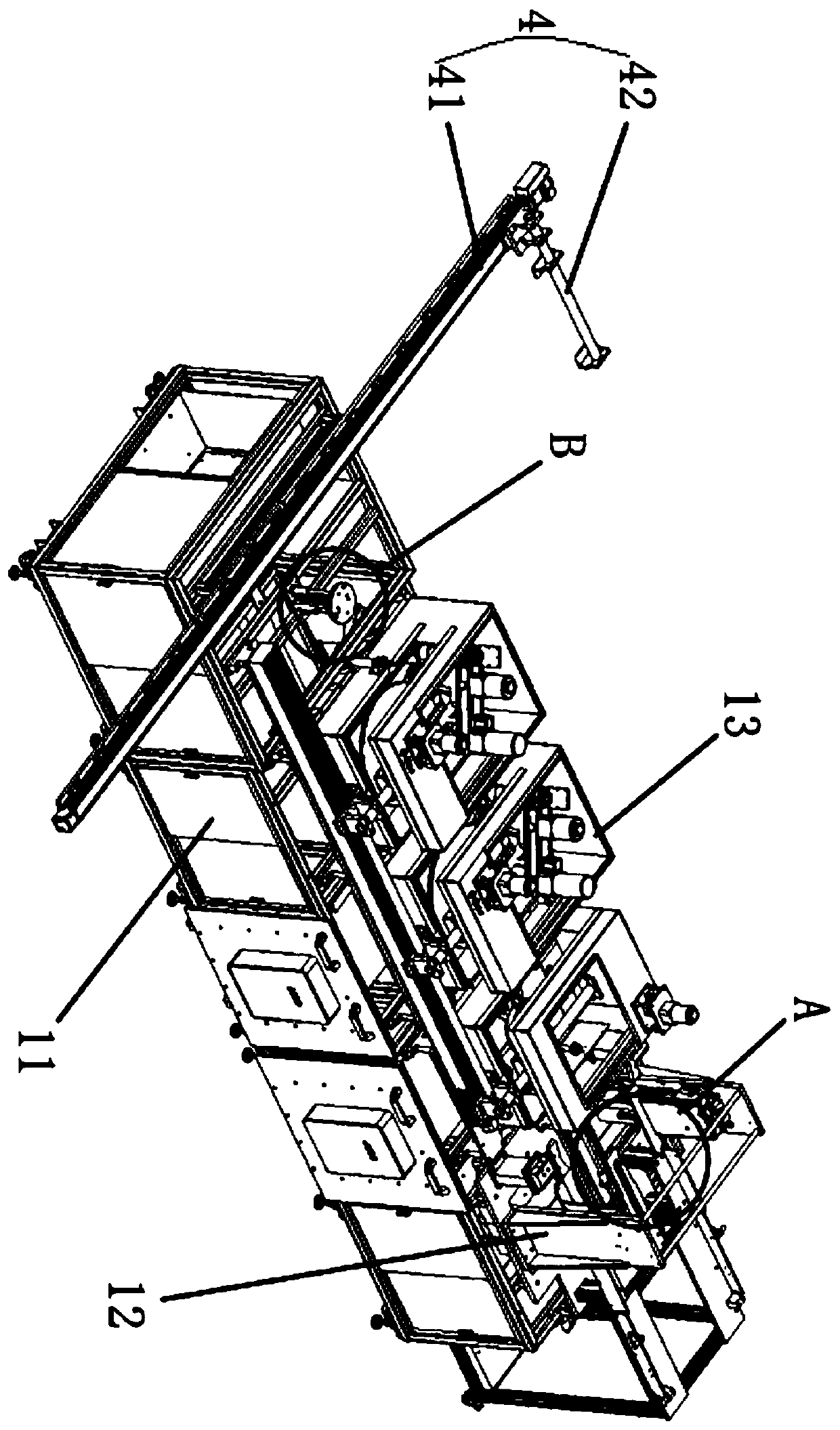

[0029] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0030] In this embodiment, there are two sets of bonding devices 2 located at both ends of the cleaning device 1. Under the action of the pick-up assembly 4, the cleaned ceramic discs are alternately fed into the two groups of bonding devices 2. The sapphire wafer is placed on the surface of the ceramic disc by the corresponding loading device 3 to carry out the lamination operation of the sapphire wafer, thereby improving the lamination efficiency.

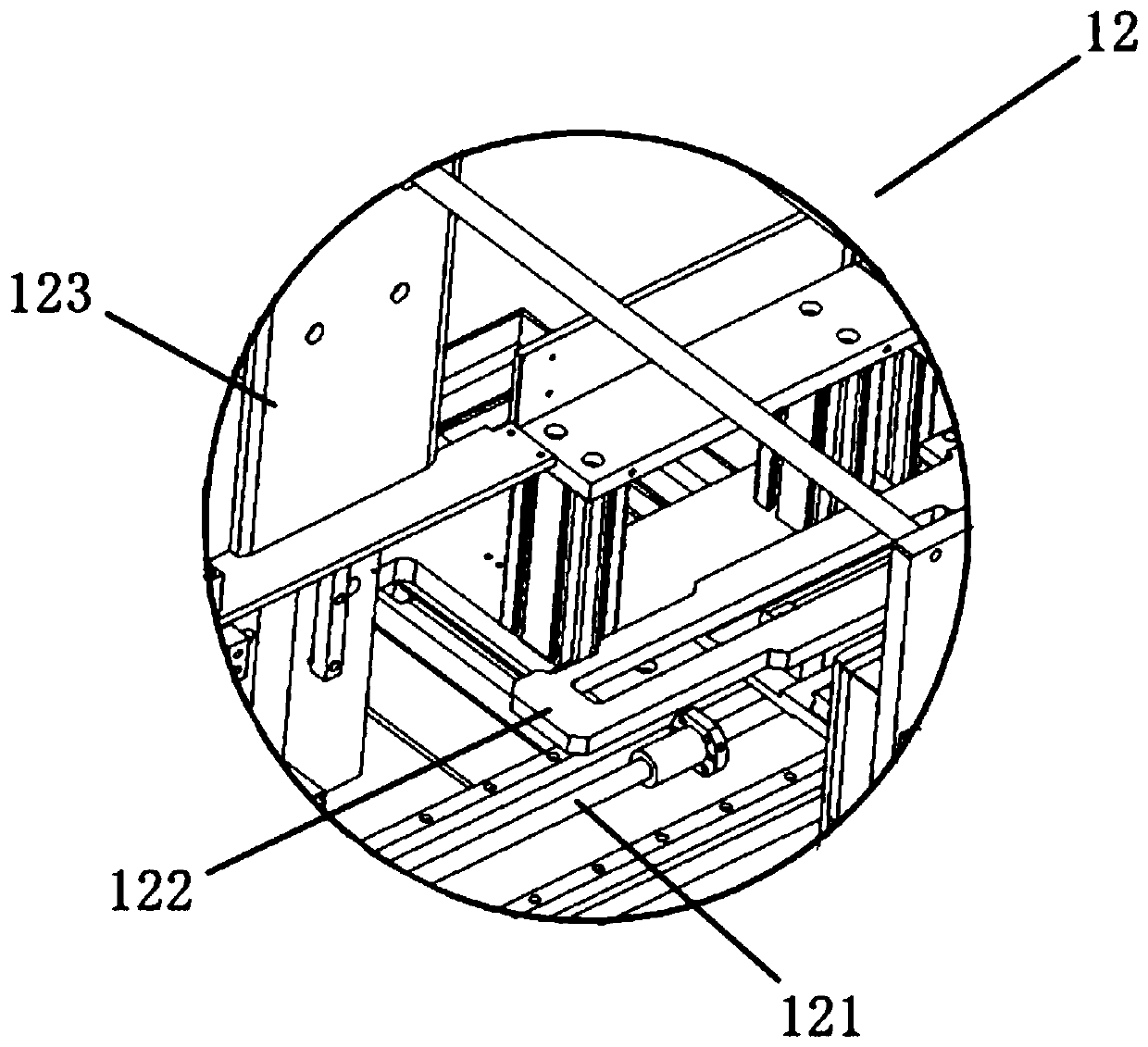

[0031] In this embodiment, three groups of cleaning stations 13 are used, one group of cleaning stations 13 close to the loading station 12 does not have a brushing structure 134 , and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com