Valve, use of such valve, separator comprising such valve and method of operating the separator

A technology for separators, valve closure, applied in the field of operating separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In the following description, the valve will be described with reference to its use in a separator that is part of a heavy duty vacuum cleaner useful in a floor grinding environment.

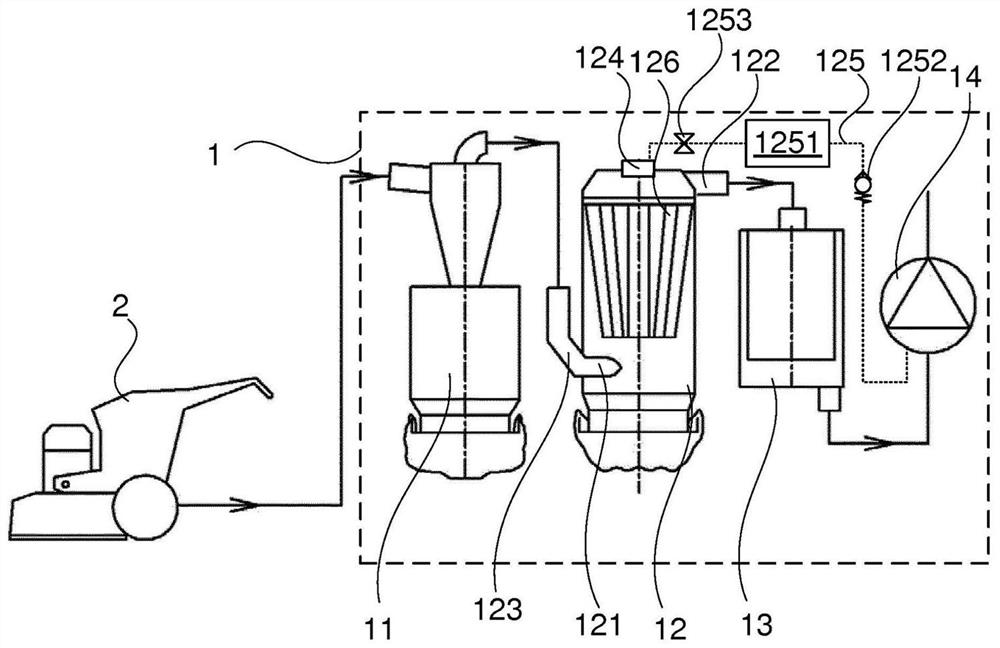

[0064] refer to figure 1 , the system comprises a floor grinder 2, which can be any type of floor grinder with a connector for emptying grinding residues. The system also comprises a heavy-duty vacuum cleaner unit 1 comprising a pre-separator 11 shown as a cyclone; a main separator 12 comprising an inlet 121, an outlet 122, an inlet valve 123, a purge valve 124 and a separator body 126, such as filters. The system also includes a rear splitter 13, such as a HEPA filter, and a suction generator 14, which may include a motor driving a fan to generate airflow.

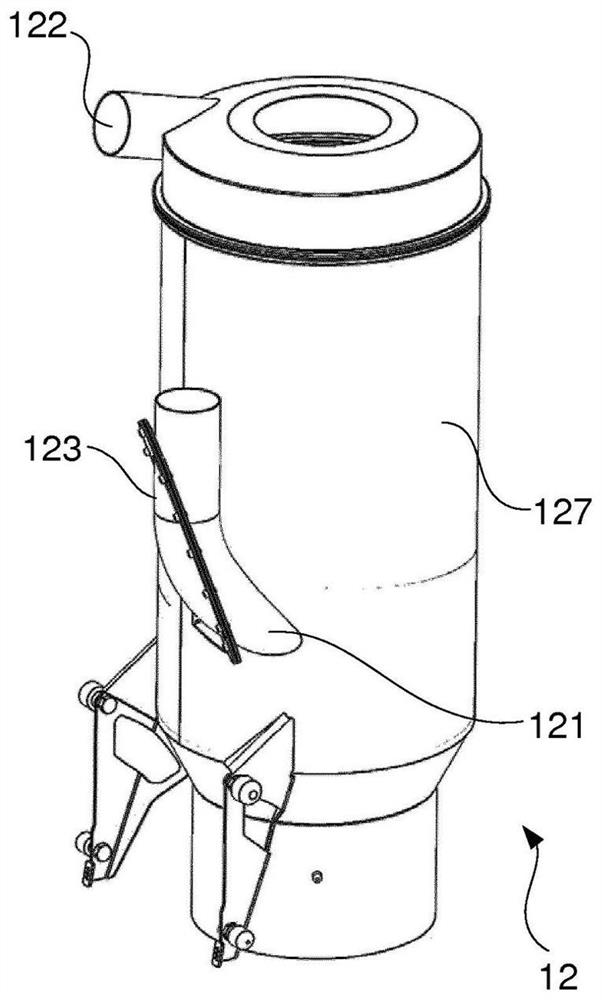

[0065] figure 2 Separator 12 is shown schematically with separator inlet 121 , outlet 122 , inlet valve 123 and housing 127 . Purge valve 124 is also visible at the top of housing 127 .

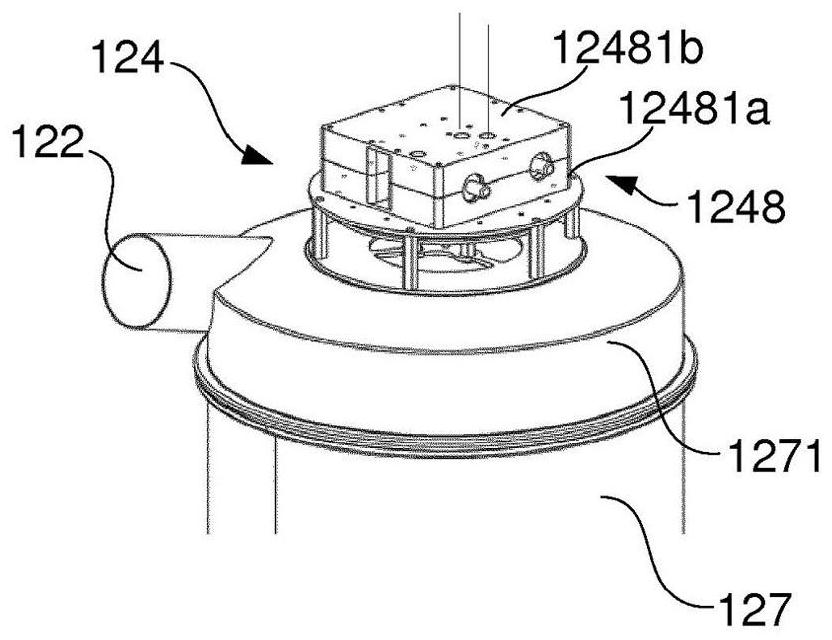

[0066] refer to Figure 3a-Figure 3b ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com