High-density lobster aquaculture method

A culture method and high-density technology, applied in the field of aquaculture, can solve the problems of poor water flow, high input cost, affecting the quality of lobsters, etc., and achieve the effect of avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

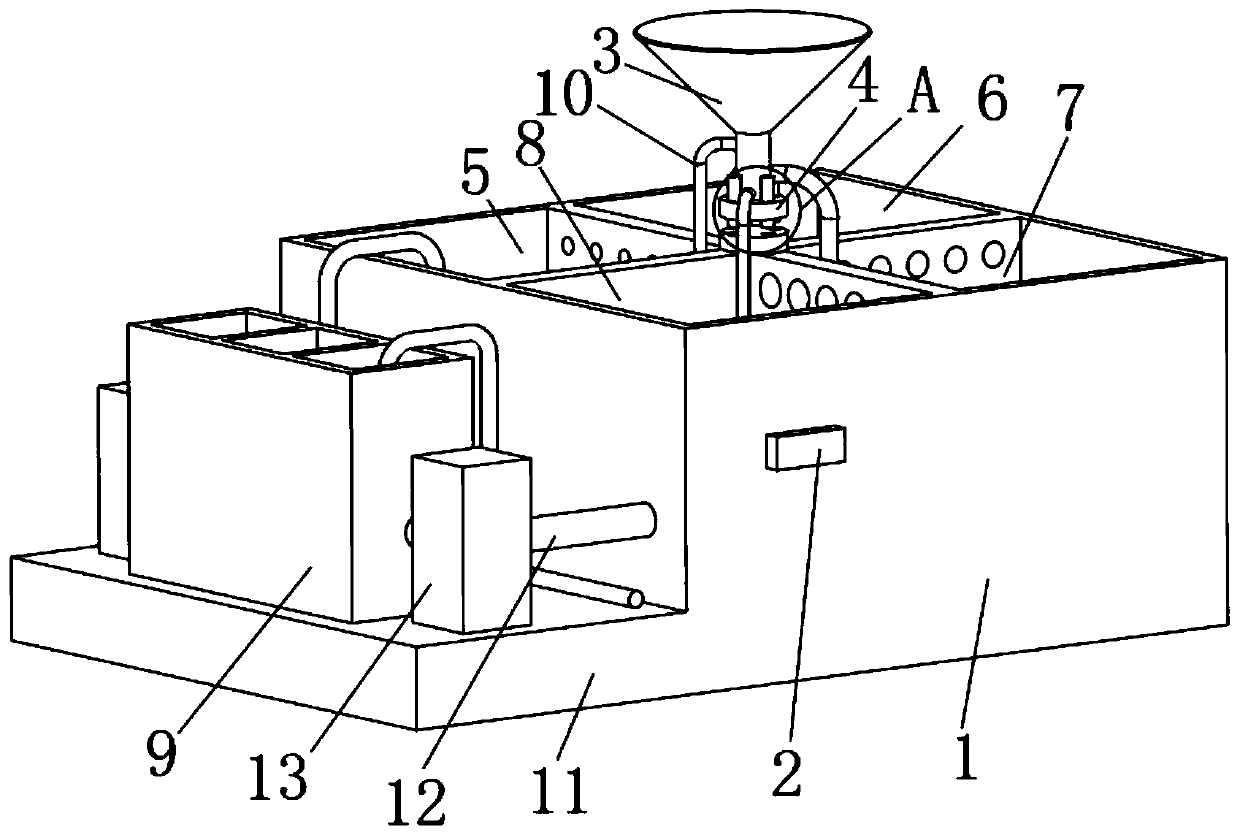

[0029] A kind of high-density lobster breeding method, comprising breeding box 1 and feeding funnel 3,

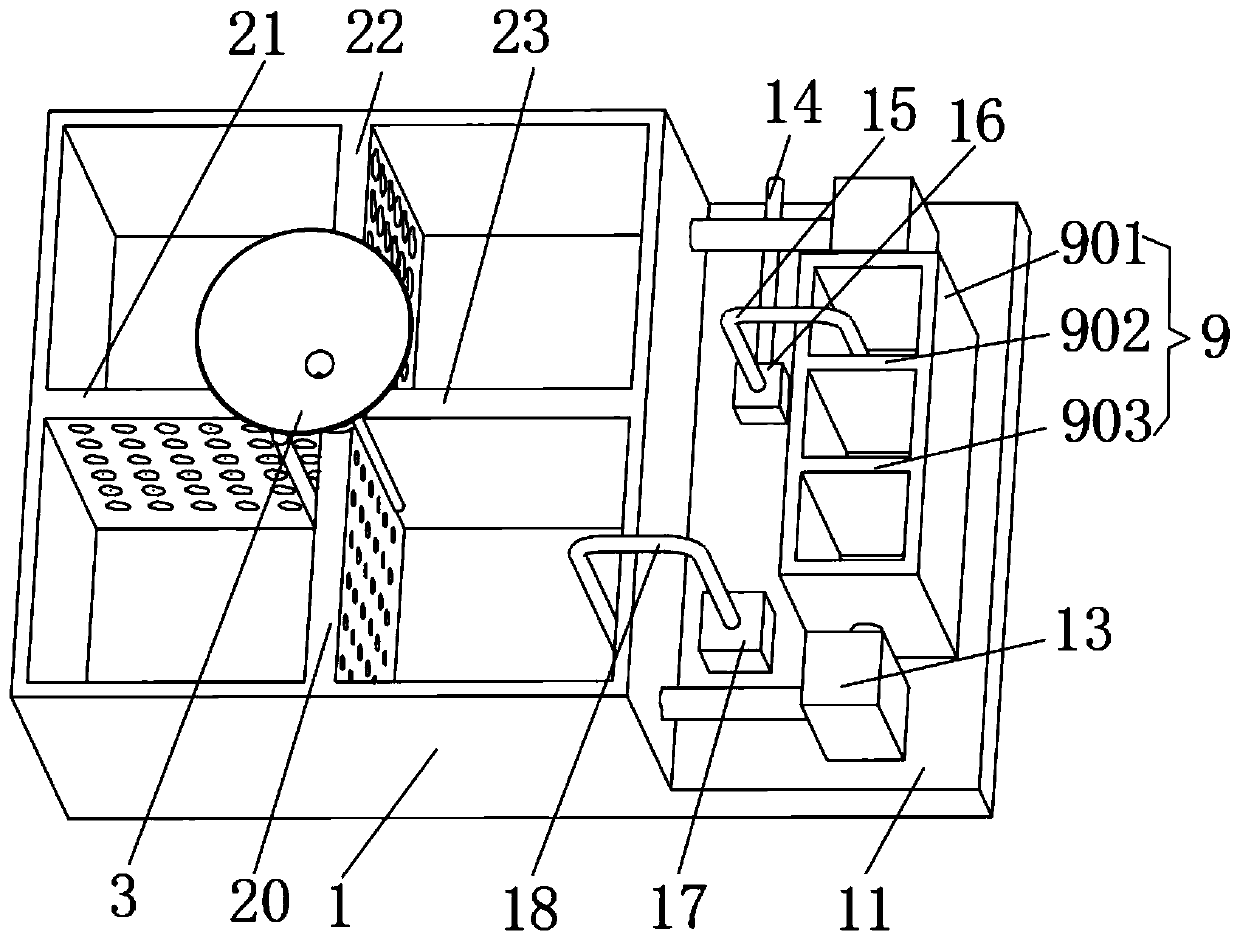

[0030] Breeding box 1: The breeding box 1 is a hollow structure. The breeding box 1 is composed of the first water tank 5, the second water tank 6, the third water tank 7 and the fourth water tank 8. The first water tank 5 and the second water tank 6 pass through the first tank. The partition plate 20 is connected, the second water tank 6 and the third water tank 7 are connected by the second partition plate 21, the third water tank 7 and the fourth water tank 8 are connected by the third partition plate 22, the fourth water tank 8 Connect with the first water tank 5 by the fourth dividing plate 23, the surfaces of the first dividing plate 20, the second dividing plate 21 and the third dividing plate 22 are all provided with through holes, and the through hole radius is determined by the first Dividing plate 20 to the 3rd dividing plate 22 increases successively, and the si...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is:

[0035] Also comprise water pipe 12 and water pump 13 in this example, water pump 13 is altogether two, and water pump 13 is provided with the upper surface of installation platform 11 symmetrically, is connected with purification unit 9 by water pipe 12 between two water pumps 13, and water pipe 12 is altogether two, One end of water pipe 12 extends to the inside of culture box 1, and the other end of water pipe 12 connects water pump 13, and the input end of water pump 13 is electrically connected with the output end of single-chip microcomputer 2, and purification unit 9 comprises clean water tank 901, filter screen 902 and gac plate 903, The water purification tank 901 is a hollow structure, and a filter screen 902 and an activated carbon plate 903 are sequentially arranged in the water purification tank 901 from right to left.

[0036] Concrete, such setting can make the water in the culture tank 1 carry ...

Embodiment 3

[0038] The difference between this embodiment and Embodiment 1 is:

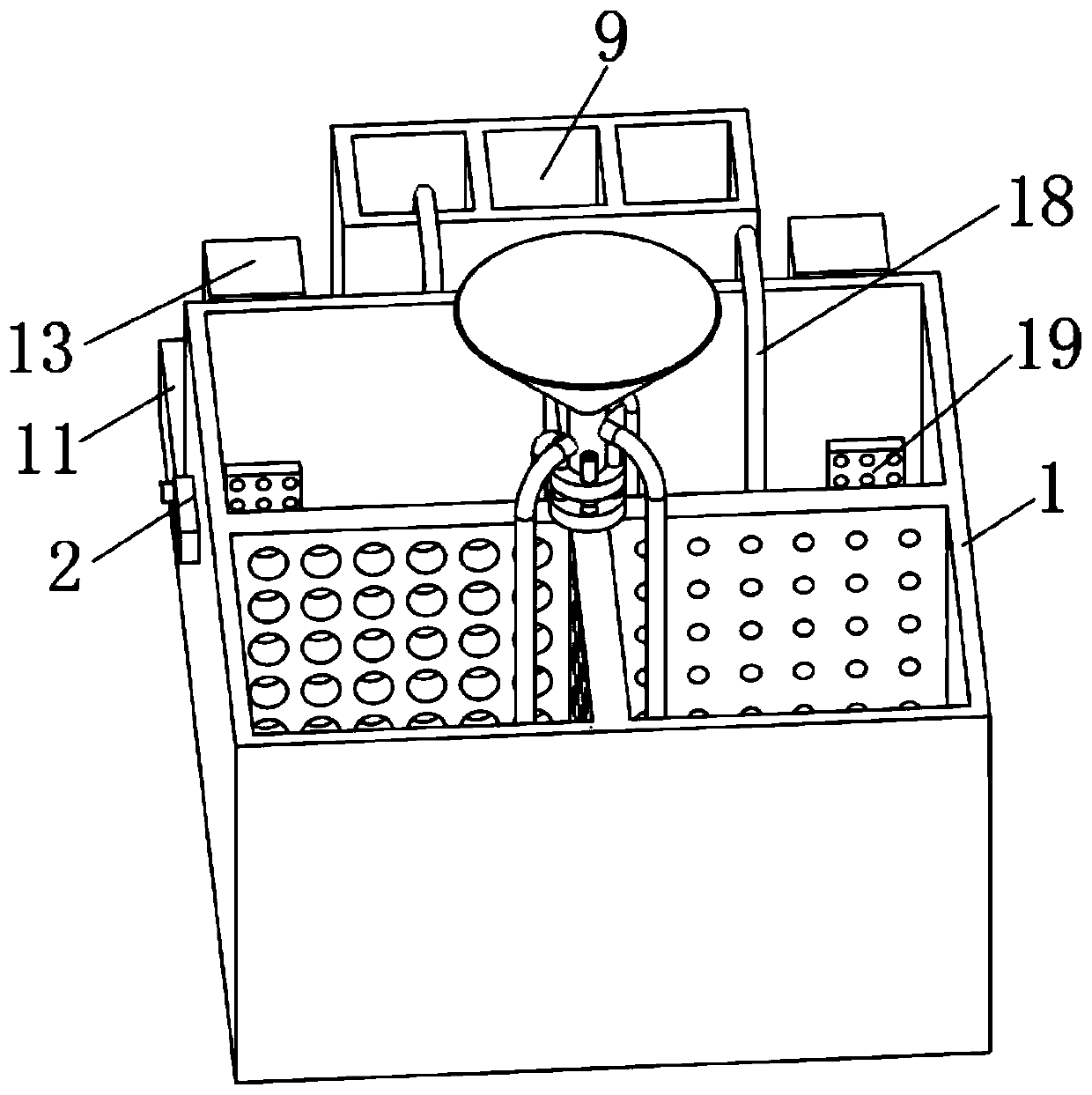

[0039] Also comprise protective net 19, totally two protective nets 19, protective net 19 is respectively arranged on the inner chamber side of the fourth tank 8 and the first tank 5, the fourth tank 8 and the first tank 5 and the water pipe 12 extend to the breeding box 1 One end of the interior is fixedly connected, and also includes a sewage suction pipe 15, a sewage discharge pipe 14 and a sludge pump 16. The sludge pump 16 is arranged on the upper surface of the installation platform 11, and one end of the sewage suction pipe 15 is connected to the mud inlet of the sludge pump 16. The other end of the sewage pipe 15 extends to the inside of the clean water tank 901, one end of the sewage pipe 14 is connected to the sludge discharge port of the sludge pump 16, the other end of the sewage pipe 14 extends to the outside of the installation platform 11, and the input end of the sludge pump 16 It is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com