3D printing additive manufacturing method of kettle-shaped thin-wall part

A 3D printing and additive manufacturing technology, applied in the field of 3D printing of pot-shaped thin-walled parts, can solve problems such as unfavorable development of the parts processing industry, part size deviation, and material springback, so as to improve 3D printing efficiency and compress printing Cycle, the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

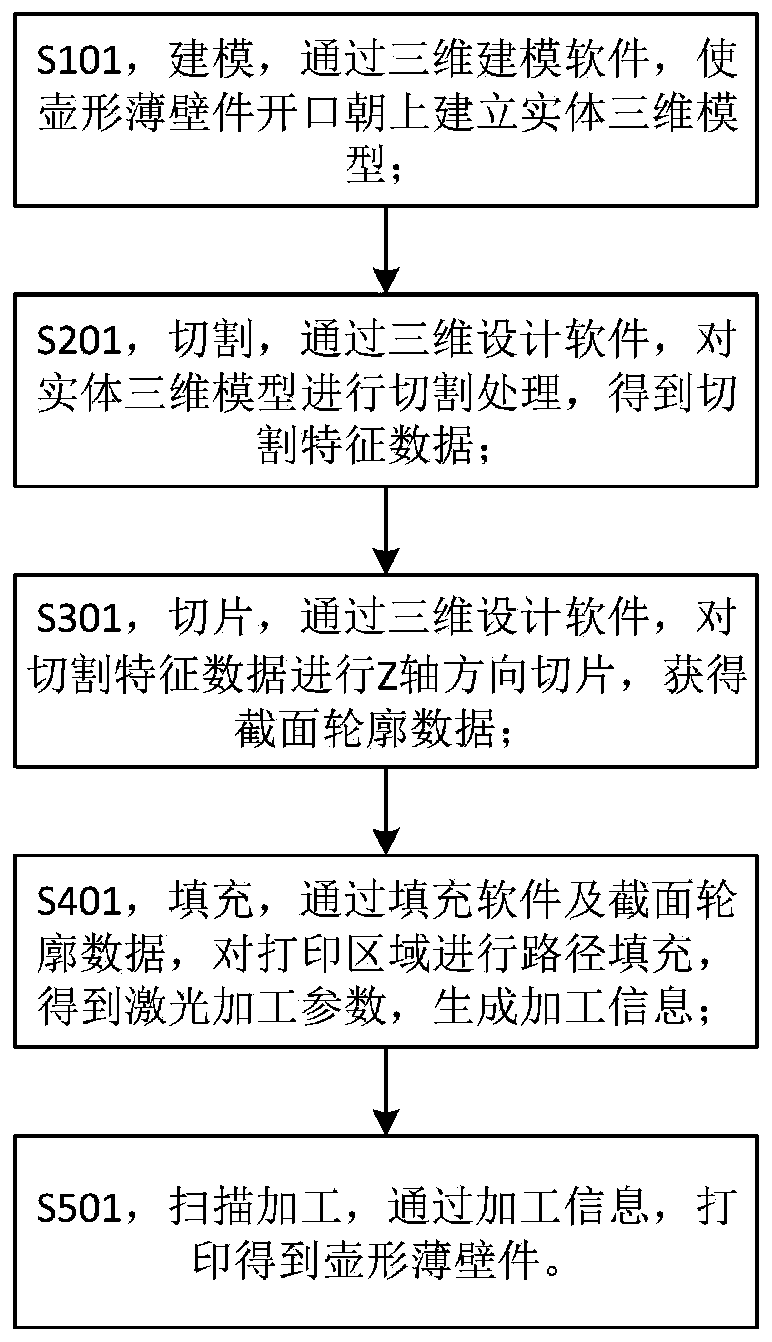

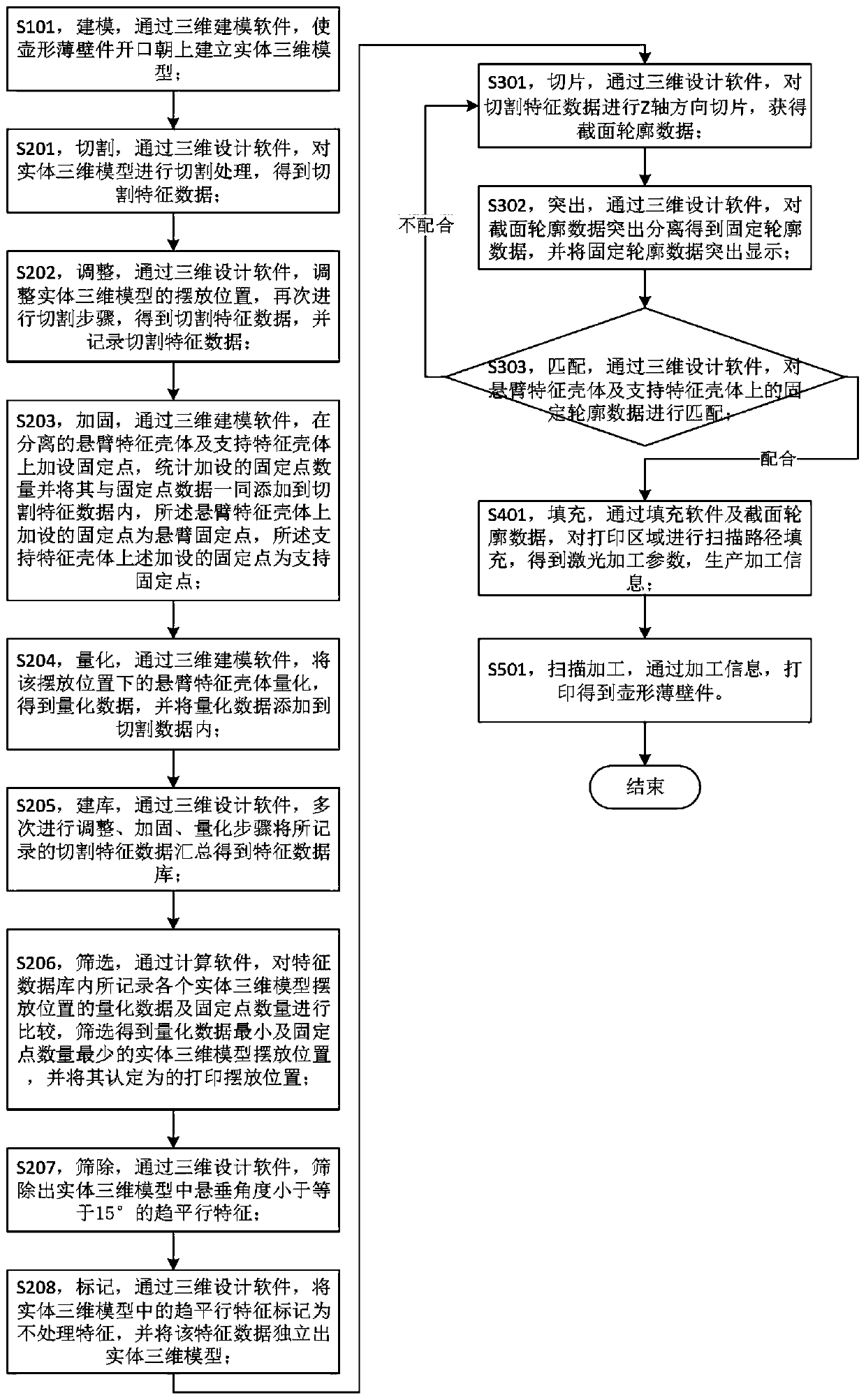

[0052] Such as figure 1 and figure 2 As shown, the present invention provides a 3D printing additive manufacturing method of a pot-shaped thin-walled part, comprising the following steps:

[0053] S101, modeling, building a solid three-dimensional model by making the opening of the pot-shaped thin-walled part upward through three-dimensional modeling software;

[0054] In the specific implementation process, in step S101, three-dimensional modeling is carried out according to the design requirements of the demand side through the three-dimensional modeling software, and the solid three-dimensional model with the opening of the pot-shaped thin-walled part is obtained, and the three-dimensional modeling data is exported.

[0055] S201, cutting, ...

Embodiment 2

[0078] This example is a preferred implementation of the 3D printing additive manufacturing method for pot-shaped thin-walled parts. The wall thickness of the pot-shaped thin-walled part shown in this example is 1.06mm, and the cantilever characteristic angle is 27°. Specifically, the steps are as follows :

[0079] Modeling: D101, through 3D modeling software, establish a solid 3D model of a pot-shaped thin-walled part with the opening facing upwards, and output *.stl format files;

[0080]Cutting: D201, use the 3D design software to cut the solid 3D model of the pot-shaped thin-walled parts and design the supporting structure; D202, import the model of the *.stl format file into Magic software; D203, use Magics software to perform Data repair, eliminate data conversion problems such as broken edges and gaps; D204, call up the printing platform in Magics software, and load the model data to the appropriate position on the platform; D205, use Magics software to physically stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com