T-shaped steel welding forming method for preventing deformation of wing plate

A welding forming, T-shaped steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large correction amount, easy bending deformation of the wing plate, frequent adjustment, etc., to reduce bending deformation, and the height of the wing plate is consistent. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

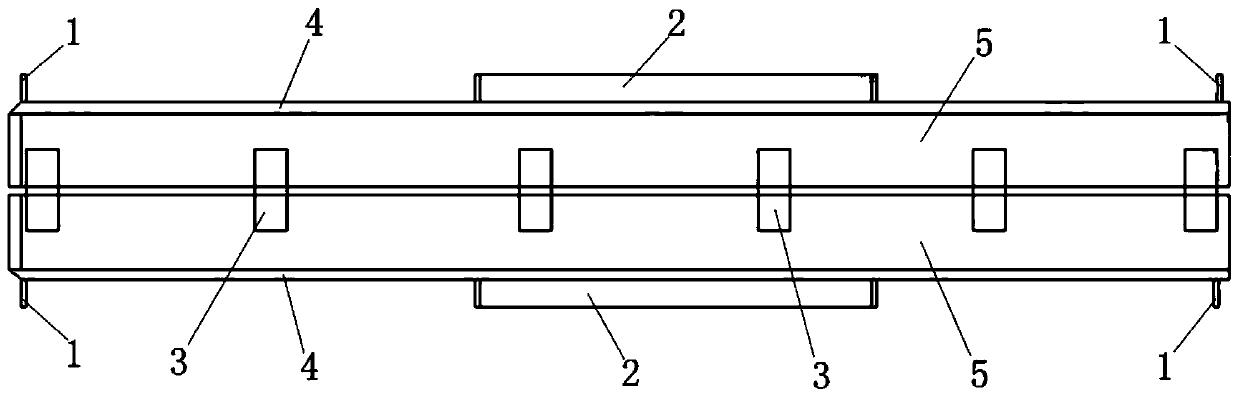

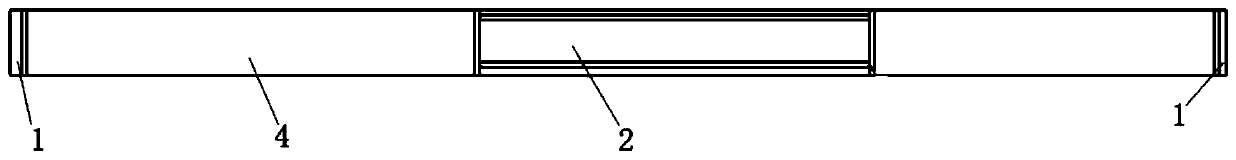

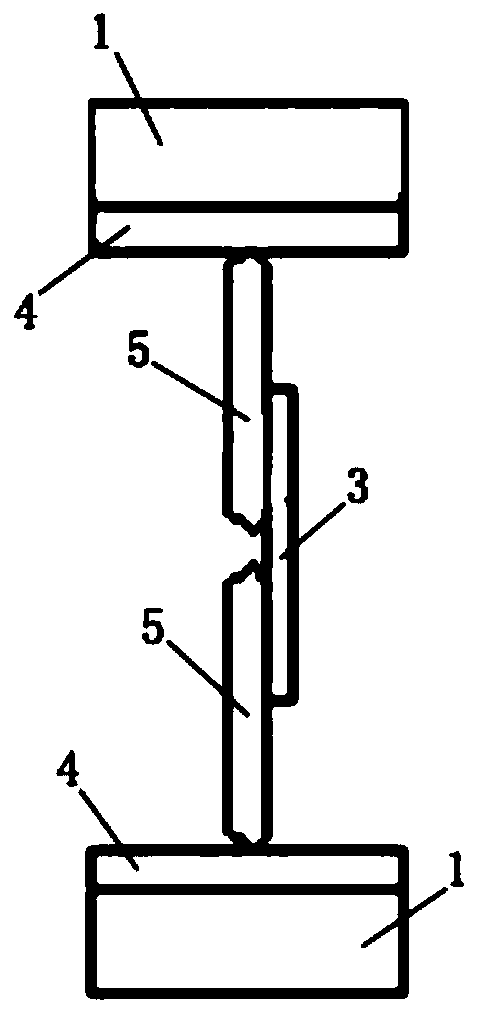

[0022] The present invention will be further described below in conjunction with the description of the drawings and the embodiments. The manner of the present invention includes but is not limited to the following embodiments.

[0023] Such as Figure 1-4 As shown, the welding forming method for the deformation of the T-shaped steel anti-wing plate provided by the present invention has a wonderful concept, simple and smooth operation, which can effectively reduce the bending deformation of the T-shaped steel wing plate during the welding process, and reduce the correction amount after the T-shaped steel welding and forming. There is no need to build temporary welding supports during the T-shaped steel forming submerged arc welding process, which saves the frequent adjustment process of temporary welding supports during the welding process, reduces the welding difficulty, and can effectively improve the T-shaped steel welding forming efficiency. The present invention uses anti-wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com