Three-eccentric metal sealing butterfly valve structure capable of replacing sealing pair on line

A metal-sealed, triple-eccentric technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve problems affecting valve sealing performance, copper corrosion, and mismatching of sealing pairs, so as to reduce the risk of leakage and ensure safe and effective operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

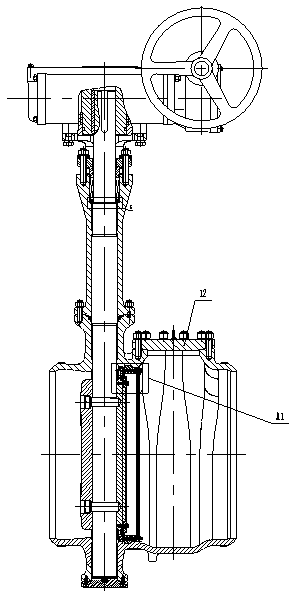

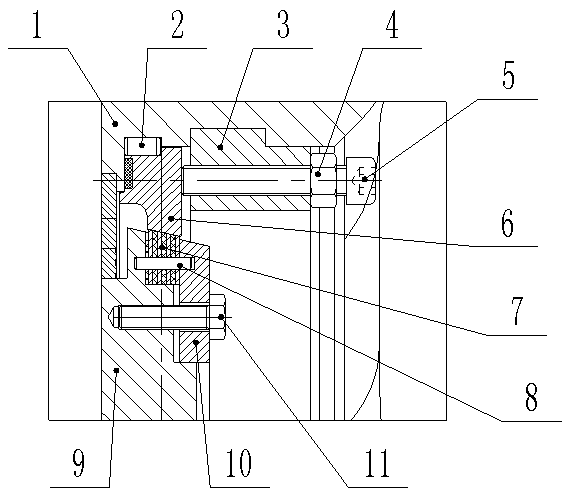

[0010] Such as Figure 1-2 As shown, a triple-eccentric metal-sealed butterfly valve structure that can replace the sealing pair online, including valve body 1, limit pin a2, three open rings 3, lock nut 4, screw a5, seat seal ring 6, multi-layer seal Ring 7, limit pin b8, butterfly plate 9, pressure plate 10, screw b11, valve body 1 is provided with valve seat sealing ring 6, and valve seat sealing ring 6 is fixed on the In the valve body 1, the three open rings 3 and the screw a5 can be locked through the lock nut 4, and the limit pin a2 is arranged between the valve seat sealing ring and the valve body, and the limit pin a2 limits the valve seat sealing ring 6, When installing the valve seat sealing ring 6, it is only necessary to align it with the limit pin a2, and the position is completely fixed. The pin holes on the valve body 1 and the pin holes on the valve seat sealing ring 6 are processed by the same tool to ensure the exact position and size. Uniformity, no deviat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com