Method for detecting airtightness of pouch battery

An air-tightness detection and soft-pack battery technology, which can be used in liquid/vacuum measurement for liquid-tightness, and fluid-tightness testing by detecting the dimensional changes of the structural components to be tested. It can solve the problem of high detection cost and unfavorable economy. Effectiveness, inability to use and other issues, to ensure accuracy, reasonable data, and improve efficiency

Inactive Publication Date: 2019-12-24

无锡格林司通科技有限公司

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] ①Air leak detection method: Including internal pressure measurement, external pressure measurement, volume measurement, deformation measurement and other differential pressure comparison methods, none of which can eliminate the influence of air pressure on the shape of flexible packaging and the change in volume

For example: during the inflation or exhaust process of the flexible packaging test, due to the change of the external pressure, the volume of the flexible packaging will change, and when the product is defective, the volume and pressure in the packaging will change, so whether the pressure detection or volume detection is used It is not obvious and cannot be applied in batches to the batch, efficient and stable detection of flexible packaging batteries on the production line

[0005] ②Halogen detection method, VOC detection: through the analysis of volatile gas, liquid specific molecules and elements to determine whether there is leakage, this method cannot be used because there will be residues in the cavity and inside the instrument

[0006] ③ Helium detection method: the detection cost of this method is too high, which is not conducive to the economic benefits of the enterprise

[0008] Although this detection process has high detection accuracy and saves the use of helium to a large extent, the cost of using helium to detect the air tightness of pouch batteries is still high, and other detection methods on the market can only be compared. Well-adapted to hard-pack batteries, there has been no more accurate and fast testing method for air-tightness testing of soft-pack batteries

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

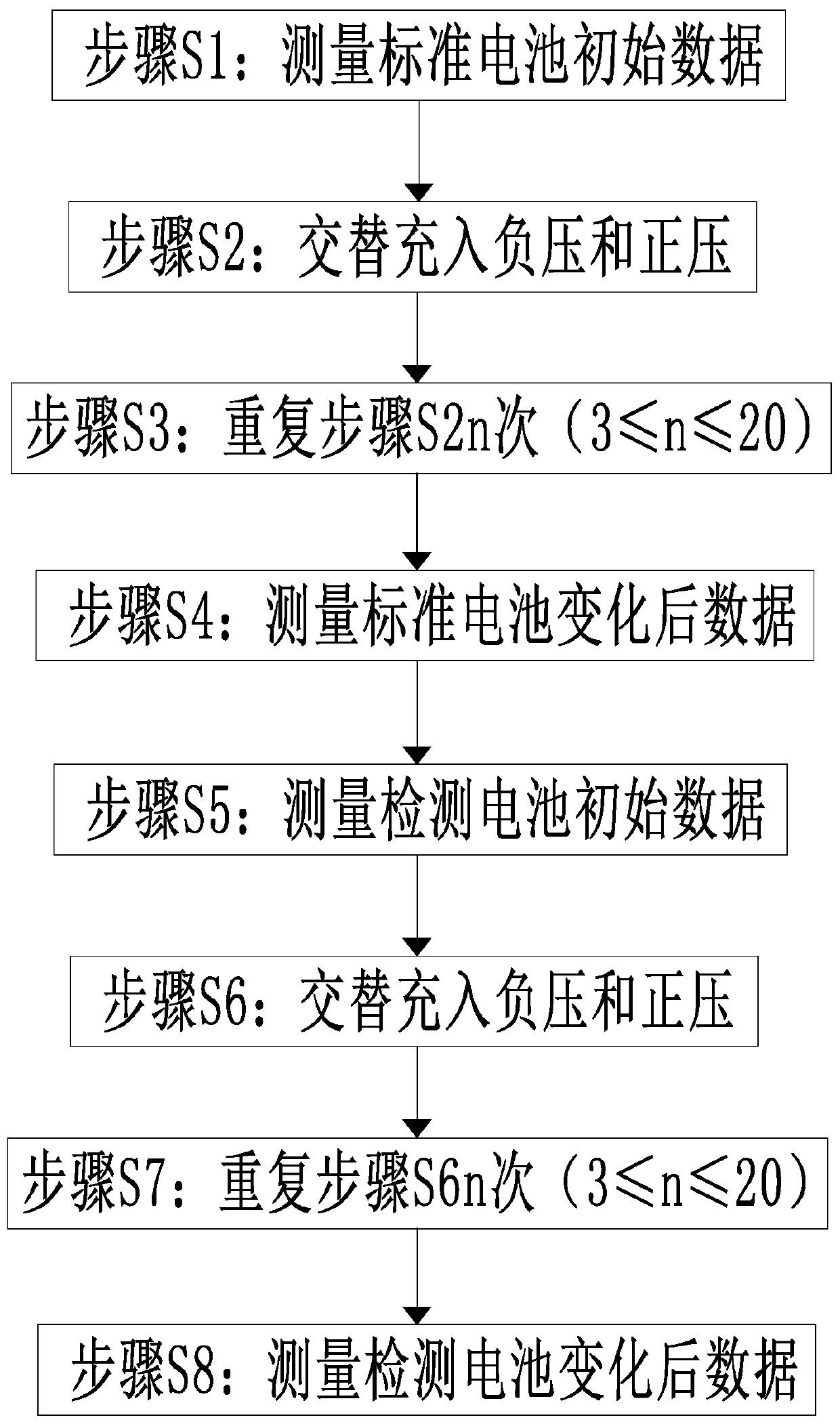

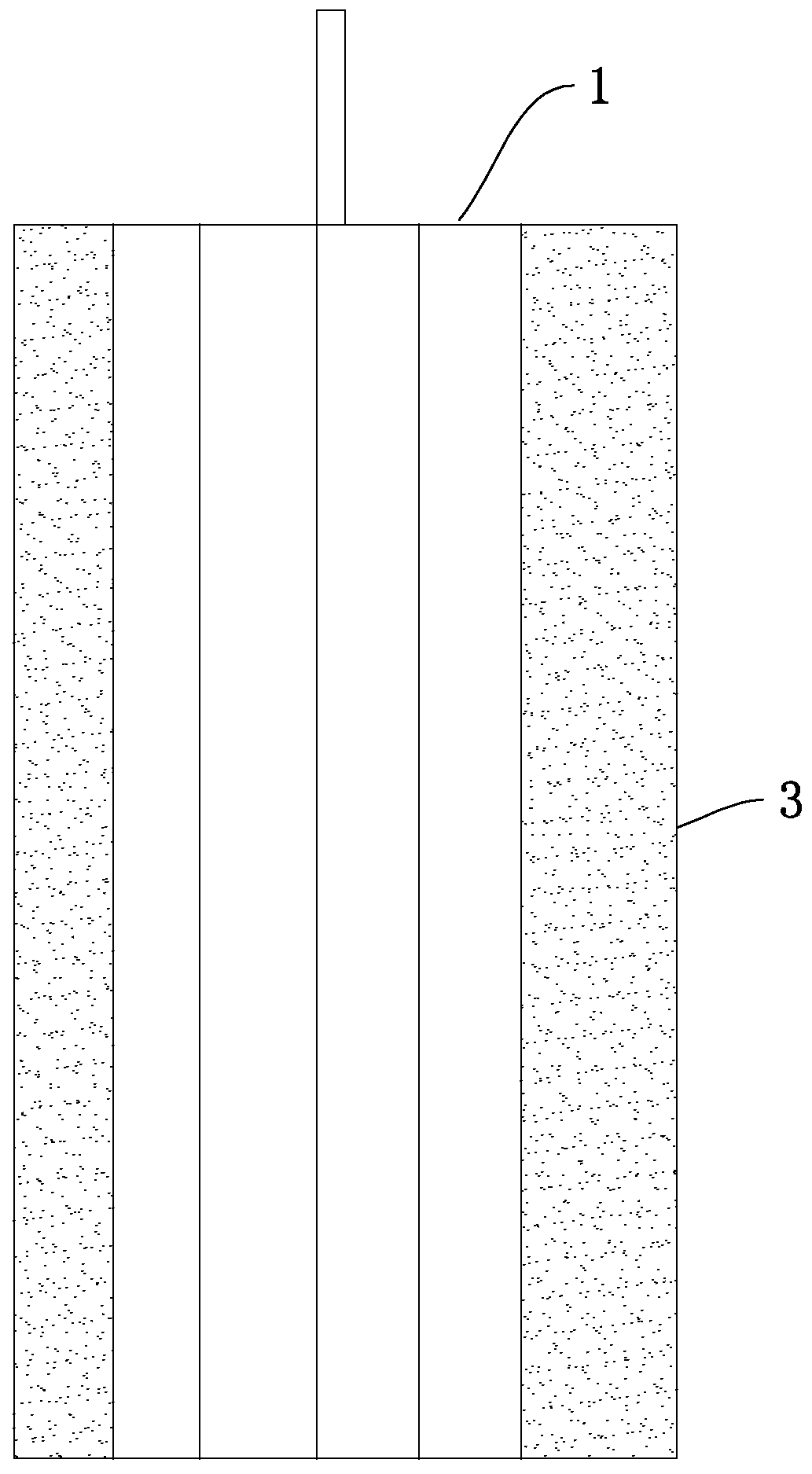

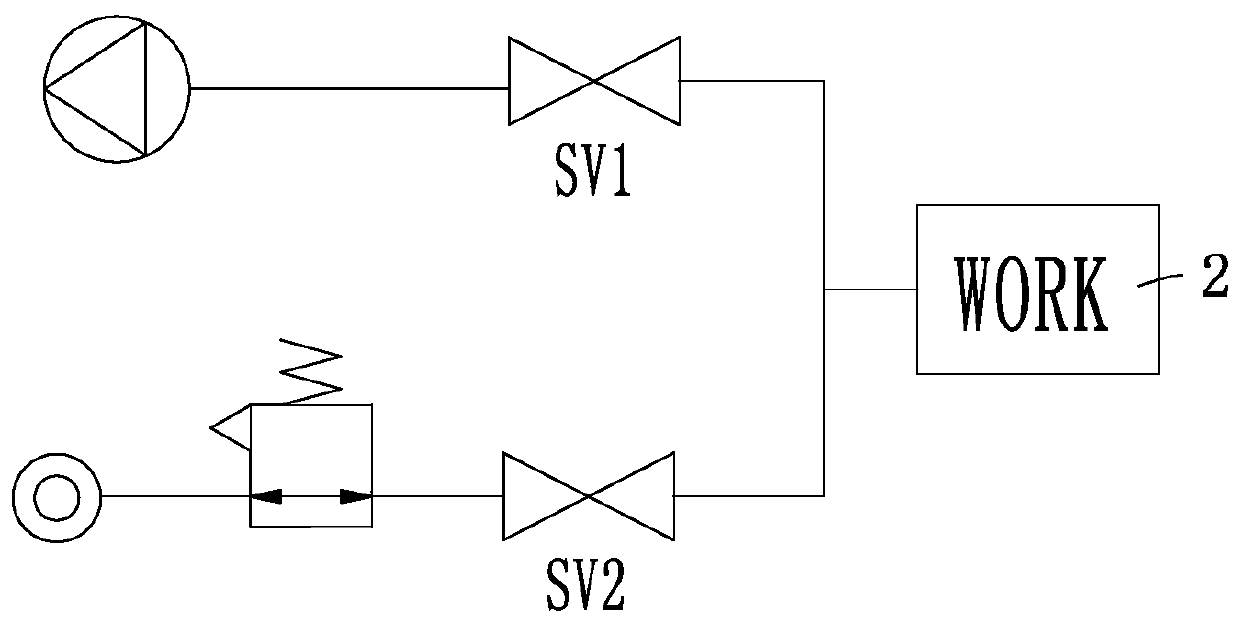

[0035] Embodiment 1: A kind of air tightness detection method of pouch battery, such as figure 1 , figure 2 and image 3 As shown, the detection method mainly includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for detecting airtightness of a pouch battery, and aims to provide a detection method with high detection efficiency and high detection accuracy. The main technical solution is to comprise a battery to be detected and a working chamber for placing the battery to be detected, and the method for detecting airtightness comprises the following steps of a, detecting theheight values of multiple groups of points on the surface of the battery by using a non-contact battery thickness measurement method; b, placing the battery to be detected in the working chamber forvacuum processing; c, filling the working chamber with positive pressure; d, repeating the steps b and c for several times; e, using the non-contact battery thickness measurement method to detect theheight value of the same point on the surface of the battery again; and f, establishing a battery leak standard, and comparing the difference in height values at the same point before and after the battery is inflated.

Description

technical field [0001] The invention relates to the field of airtightness detection of soft-packaged batteries, in particular to an airtightness detection method for soft-packaged batteries. Background technique [0002] With the rapid development of the lithium battery industry, it is now widely produced and used in all walks of life. According to the needs of the production process, the battery must be sealed after packaging. Due to technical limitations, it is only possible to effectively seal the hard-packed battery. Detection, the sealing detection method for pouch batteries is still in the bottleneck stage. [0003] Defects and deficiencies of existing technical means for sealing inspection of flexible packaging batteries: [0004] ①Air leak detection method: Including internal pressure measurement, external pressure measurement, volume measurement, deformation measurement and other differential pressure comparison methods, none of which can eliminate the influence of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M3/36

CPCG01M3/36

Inventor 杨峰吴风平

Owner 无锡格林司通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com