A Debugging Method for Parallel Grating Surface of Compressor in Ultrashort Pulse Laser System

An ultra-short pulse laser and compressor technology, which is applied to lasers, laser parts, phonon exciters, etc., can solve the problems of many professional instruments, complicated monitoring optical path structure and adjustment ideas, and complicated operation, etc. Intuitive principle and high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

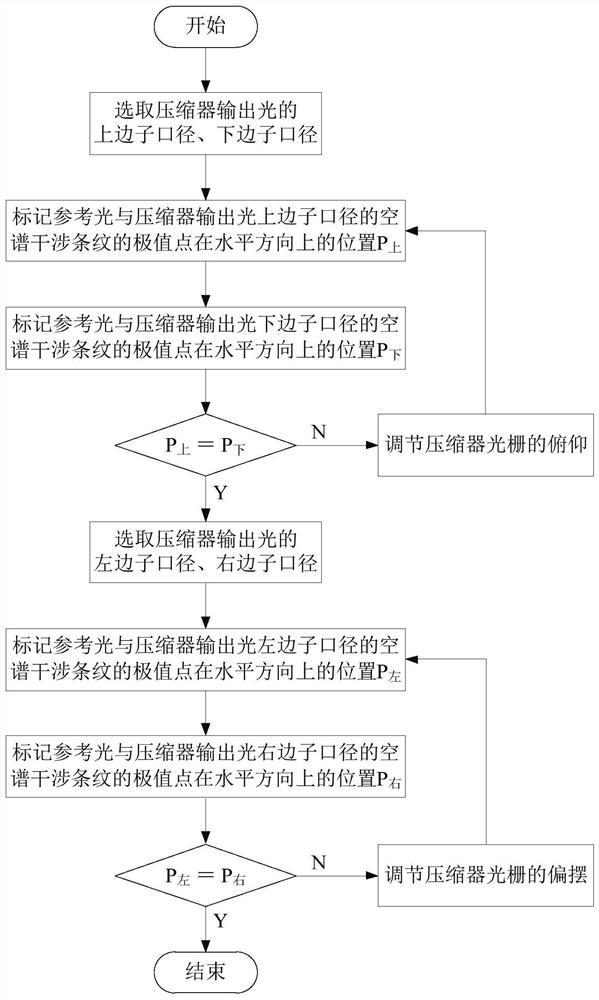

[0036] Such as figure 1 and figure 2 As shown, a parallel debugging method for the grating plane of the ultrashort pulse laser system compressor, including the following steps:

[0037] S1. Use the spatial spectrum interference information of the upper sub-aperture and the lower sub-aperture of the reference light and the output light of the compressor to adjust the parallelism of the face of the compressor grating in the vertical direction, specifically:

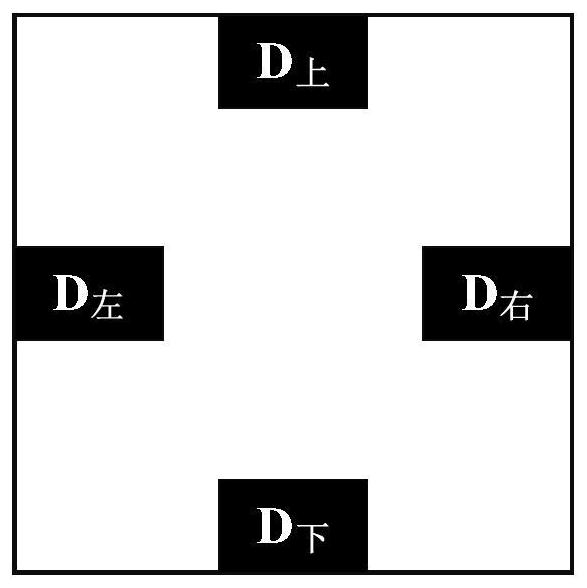

[0038] S11: Select the upper sub-aperture D of the output light of the compressor 上 and lower sub-caliber D 下 ;

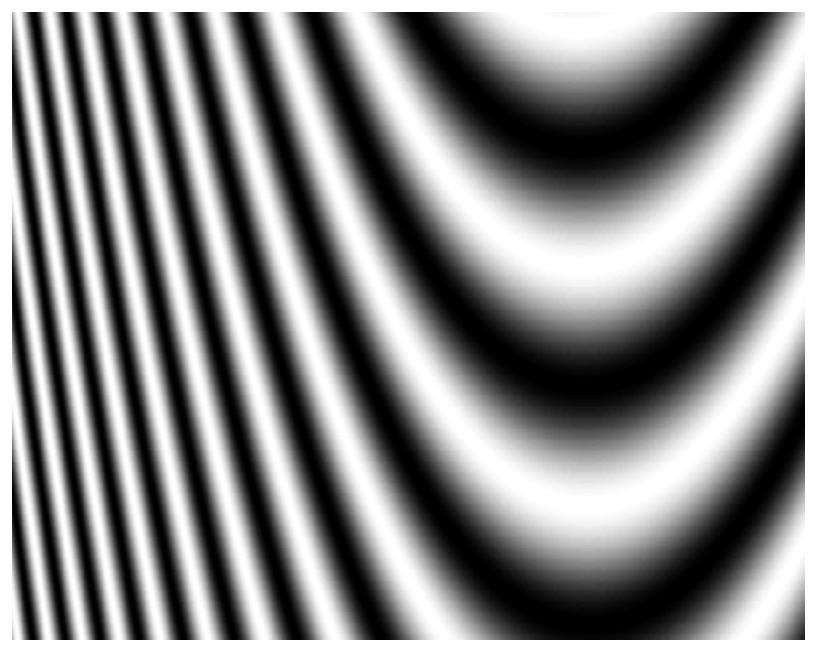

[0039] S12: Collect the reference light and the upper sub-aperture D of the compressor output light 上 The space-spectrum interference information of , mark the position P of the extreme point of the space-spectrum interference fringe in the horizontal direction 上 , as shown in Figure 3, Figure 3(a) shows that there are extreme points in the space-spectrum interference fringes, and the binarization process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com