Liquid-proof connector

一种连接器、防液的技术,应用在车辆连接器、连接、电动发电机连接器等方向,能够解决伸长量小、端子保持孔裂开或剥落等问题,达到高防液性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

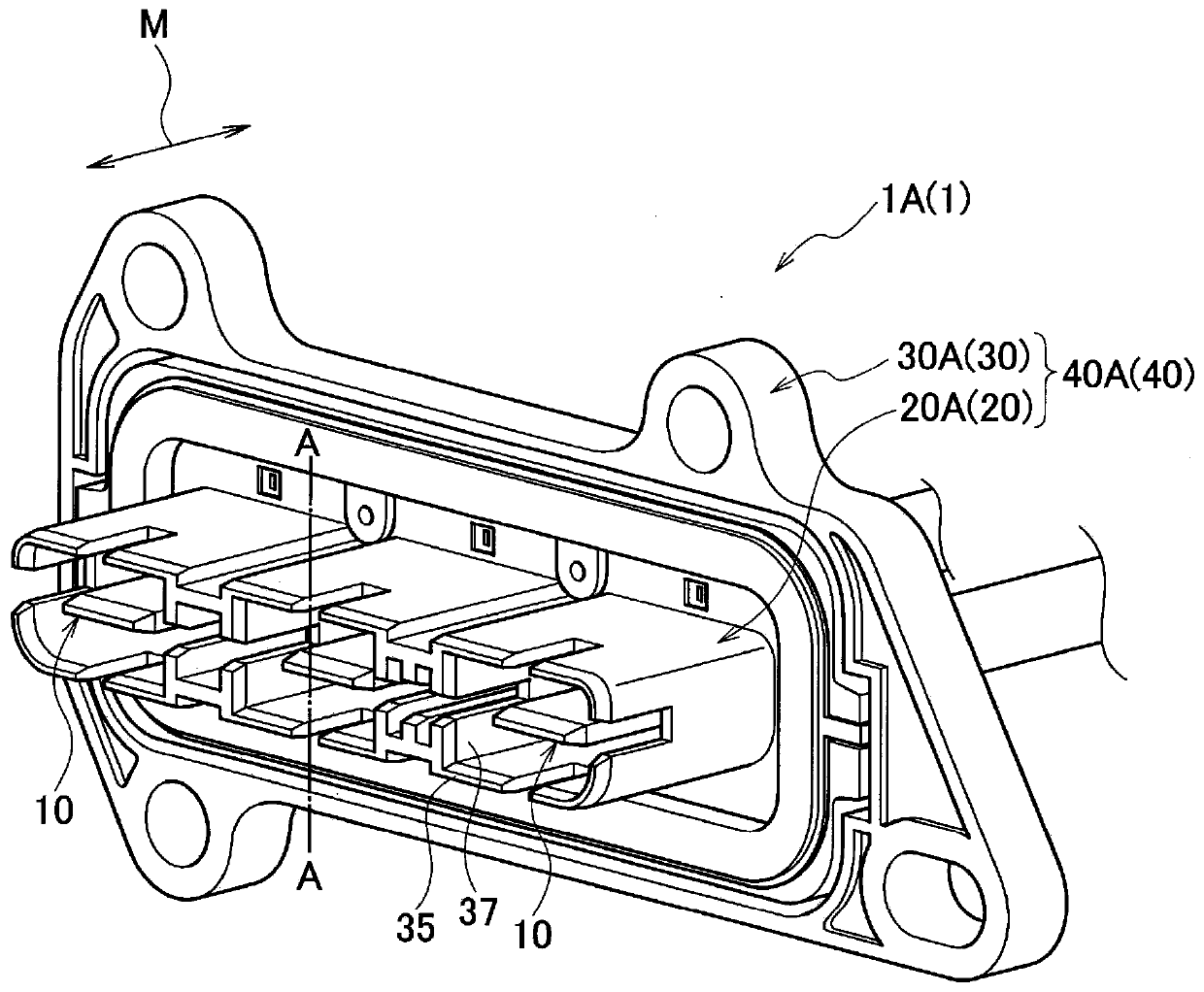

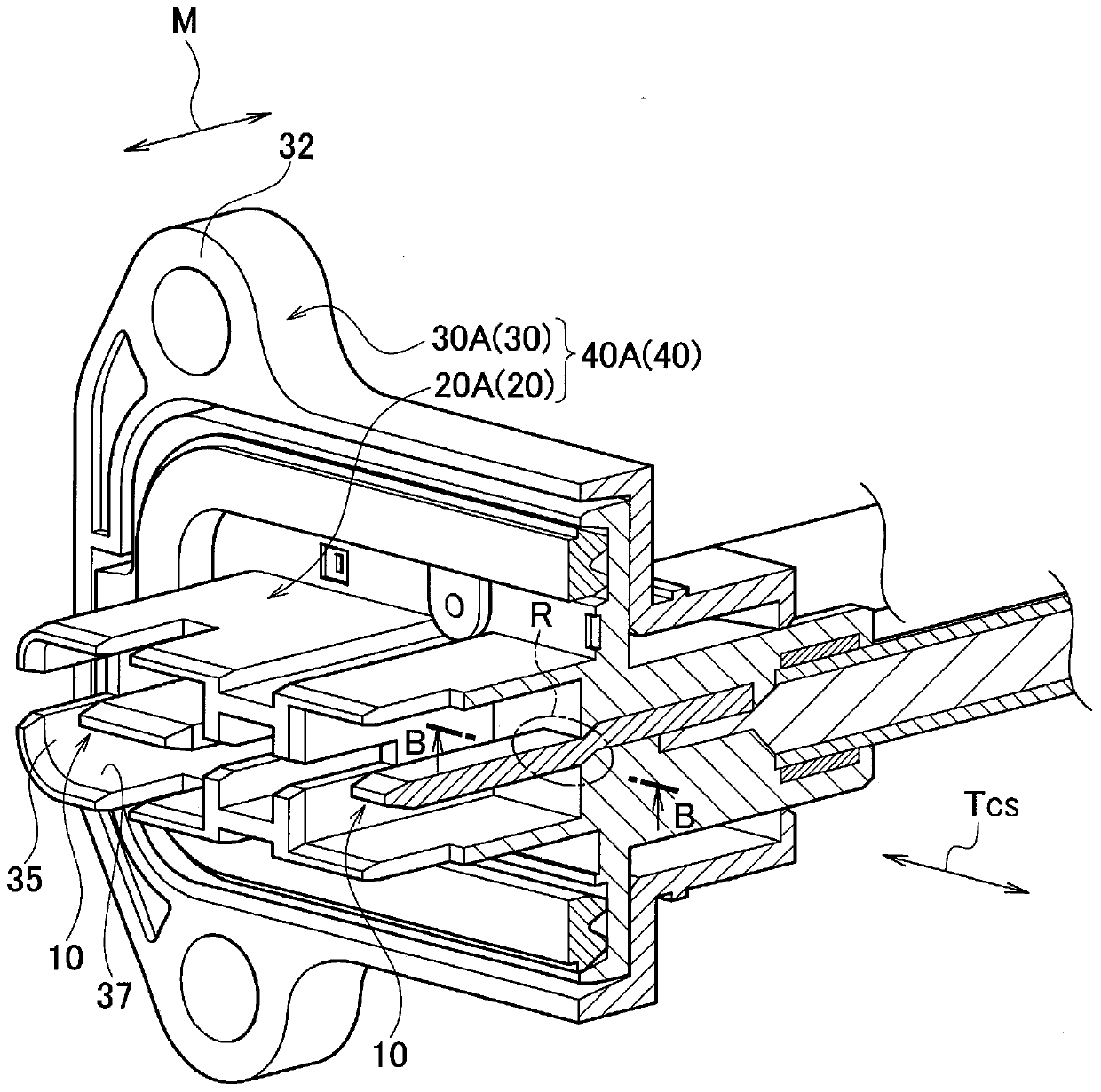

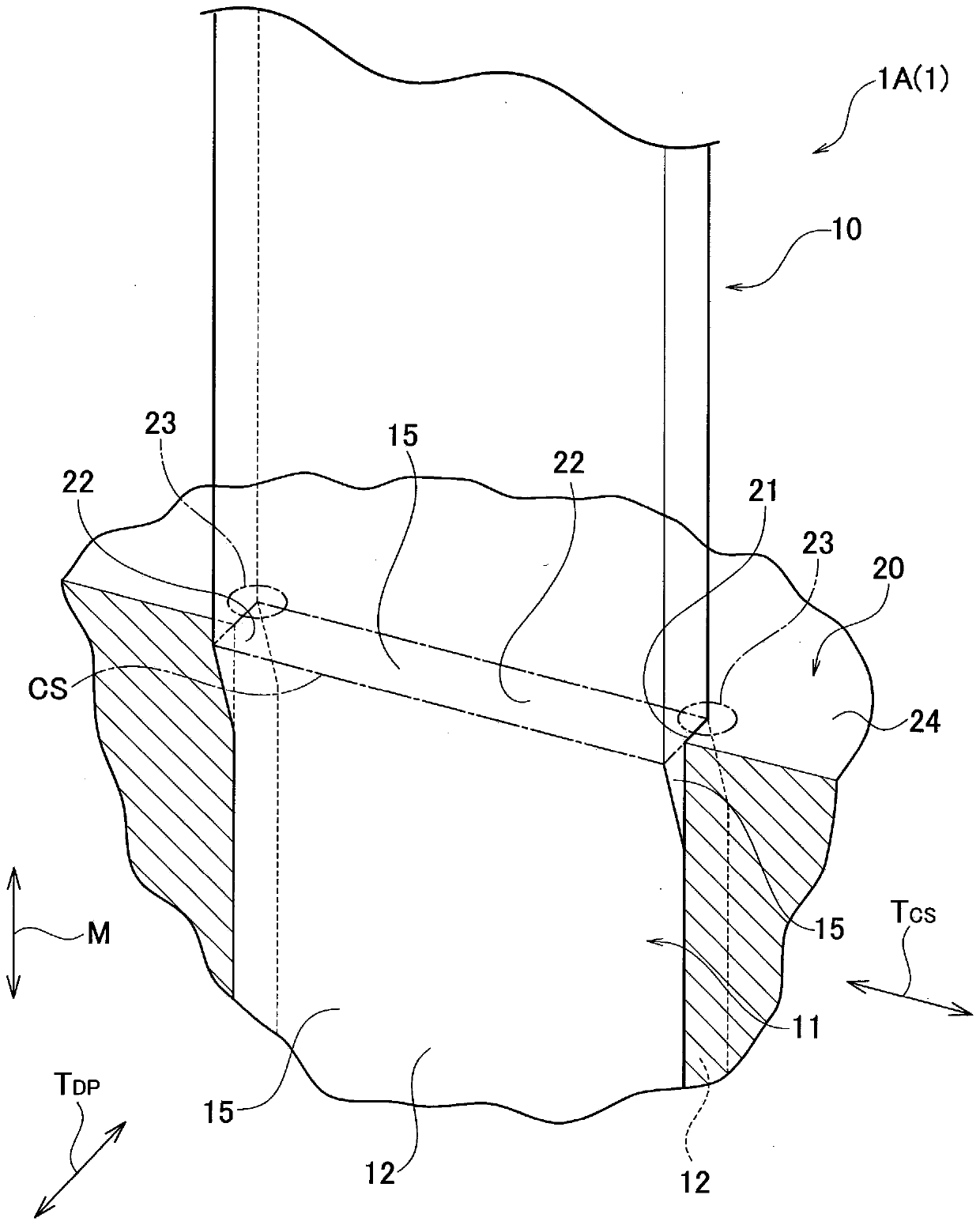

[0026] figure 1 is a perspective view of the liquid-proof connector 1A according to the first embodiment; figure 2 is included along figure 1 A perspective view of the liquid-proof connector 1A according to the first embodiment of the section taken by the line A-A; image 3 is included along figure 2 The section intercepted by the line B-B of figure 2 Magnified view of range R shown.

[0027] Such as figure 1 and 2 As shown, the liquid-proof connector 1A (1) according to this embodiment includes a columnar terminal 10 and a connector 40A (40) including a connector housing 20A (20) and a connector housing peripheral portion 30A ( 30).

[0028] Such as figure 2 and 3 As shown, a terminal holding hole 21 for holding the inserted columnar terminal 10 is formed in the connector housing 20A of the liquid-proof connector 1A. In the liquid-proof connector 1A, by bringing the surface 12 into close contact with the inner surface 22 of the terminal holding hole 21, the hold...

example 1

[0101] (1. Tensile strength)

[0102]

[0103] 60 mm high x 60 mm wide x 2 mm defined in ASTM D732 by using syndiotactic polystyrene resin XAREC (registered trademark) S131 (material number R1) manufactured by Idemitsu Kosan Co., Ltd. Thick fiber-reinforced plastic panels. This fiber-reinforced plastic plate 28 was used as sample No. A-1. Figure 4 A schematic plan view of a fiber reinforced plastic plate 28 is shown. exist Figure 4 , the arrow OR indicates the direction in which the fibers are oriented in the fiber reinforced plastic, the reference sign M indicates the MD direction, and the reference sign TD indicates the TD direction. The direction OR in which the fibers are oriented in the fiber-reinforced plastic sheet 28 coincides with the MD direction.

[0104] Subsequently, tensile test pieces 29M and 29T of 20 mm width×60 mm length×2 mm thickness were cut out from the fiber-reinforced plastic plate 28 . Such as Figure 5 As shown, tensile test piece 29M is cut...

example 2 to 4 and comparative example 1

[0154] (1. Tensile strength)

[0155]

[0156] Except for using material No.R2 to R5 shown in Tables 1 to 3 instead of material No.R1, the fiber-reinforced plastic plate 28 was manufactured as in the of "1. Tensile strength" of Example 1 (test Sample No.A-2 to A-5). Sample Nos. A-2 to A-4 and A-5 are samples of Examples 2 to 4 and Comparative Example 1, respectively.

[0157] Subsequently, as in Example 1, tensile test pieces 29M and 29T of 20 mm wide x 60 mm long x 2 mm thick were cut out from the fiber-reinforced plastic plate 28 (sample Nos. A-2 to A-5).

[0158]

[0159] Tensile strength (MPa) was measured as in Example 1 except that the tensile test pieces 29M and 29T cut out from the fiber-reinforced plastic plate 28 (Sample Nos. A-2 to A-5) were used.

[0160] The results of tensile strength are shown in Tables 1 to 3.

[0161] (2. Air tightness before thermal shock test)

[0162]

[0163] Except for using material No.R2 to R5 shown in Tables 1 to 3 instead o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com