Organic transistor and method for manufacturing the same

A technology of organic transistors and manufacturing methods, applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as unpredictable transistor component performance, and achieve high alignment and crystallinity, high effect, and excellent transistors The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

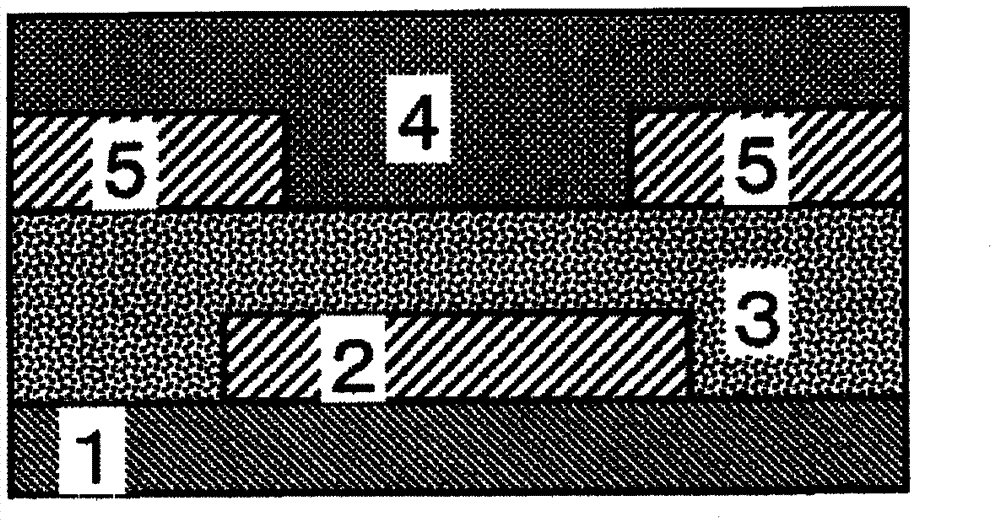

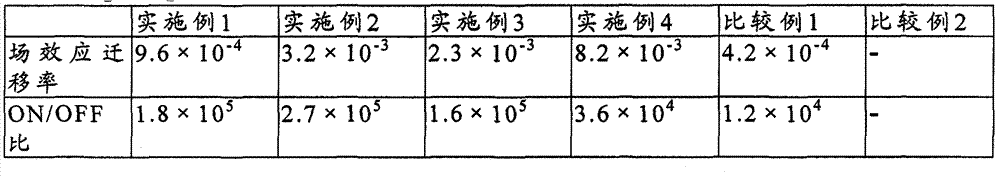

[0074] Below, create figure 1 The test element having the bottom-gate-bottom-contact (BGBC) structure shown was used for evaluating the characteristics of the organic transistor of the present invention. From the measured values of Id-Vg and Id-Vd, the field-effect mobility and ON / OFF value were calculated.

Synthetic example 1

[0075] (Synthesis Example 1) Synthesis of Fluoro(meth)acrylate Polymer (1)

[0076]Into a glass flask equipped with a stirring device, a condenser, a thermometer, and a dropping funnel, 27 parts by weight of a fluorinated (meth)acrylate (A-1) and a polyamide as a non-fluorine (meth)acrylate were weighed and added. 21.6 parts by weight of propylene oxide monomethacrylate (average degree of polymerization: 5), 5.4 parts by weight of 3-methacryloxypropyltris(trimethylsiloxy)silane, 66.1 parts by weight of methyl ethyl ketone (MEK) as a polymerization solvent parts by weight, and 0.54 parts by weight of dimethyl 2,2'-azobis(2-methylpropionate) as a polymerization initiator. In addition, 63 parts by weight of (A-1), 50.4 parts by weight of polyoxypropylene monomethacrylate (average degree of polymerization: 5), 3-methacryloyloxypropyl tris(trimethylsiloxane) and 12.6 parts by weight of silane, 124.2 parts by weight of MEK, and 1.26 parts by weight of dimethyl 2,2'-azobis(2-methylp...

Synthetic example 2

[0077] (Synthesis Example 2) Synthesis of Fluorinated (Meth)acrylate Polymer (2)

[0078] 9.3 g of (A-1) as a fluorinated (meth)acrylate and 4-(6-acryloyloxyhexyloxy)benzene as a non-fluorinated (meth)acrylate were weighed into a glass polymerization tube. 18 g of benzene, 220 ML of toluene as a polymerization solvent, 2,2' azobis(2,4-dimethylvaleronitrile) and 0.55 g of (A-1) as a polymerization initiator. After blowing nitrogen stream into this solution to remove oxygen, it was made to react at 60 degreeC for 24 hours. After completion of the reaction, the reaction liquid was concentrated, and the concentrated liquid was added dropwise to 1 L of methanol. The precipitated solid was sufficiently washed with methanol to obtain a fluorinated (meth)acrylate polymer (2). The polystyrene-equivalent weight average molecular weight of the obtained polymer (2) by GPC was Mw=47000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com