Vehicle-mounted camera module structure

A module structure, vehicle-mounted camera technology, applied in the field of vehicle-mounted cameras, can solve the problems of sealing ring wrinkling, failure to consider the impact of imaging, failure, etc., to achieve the effect of avoiding wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

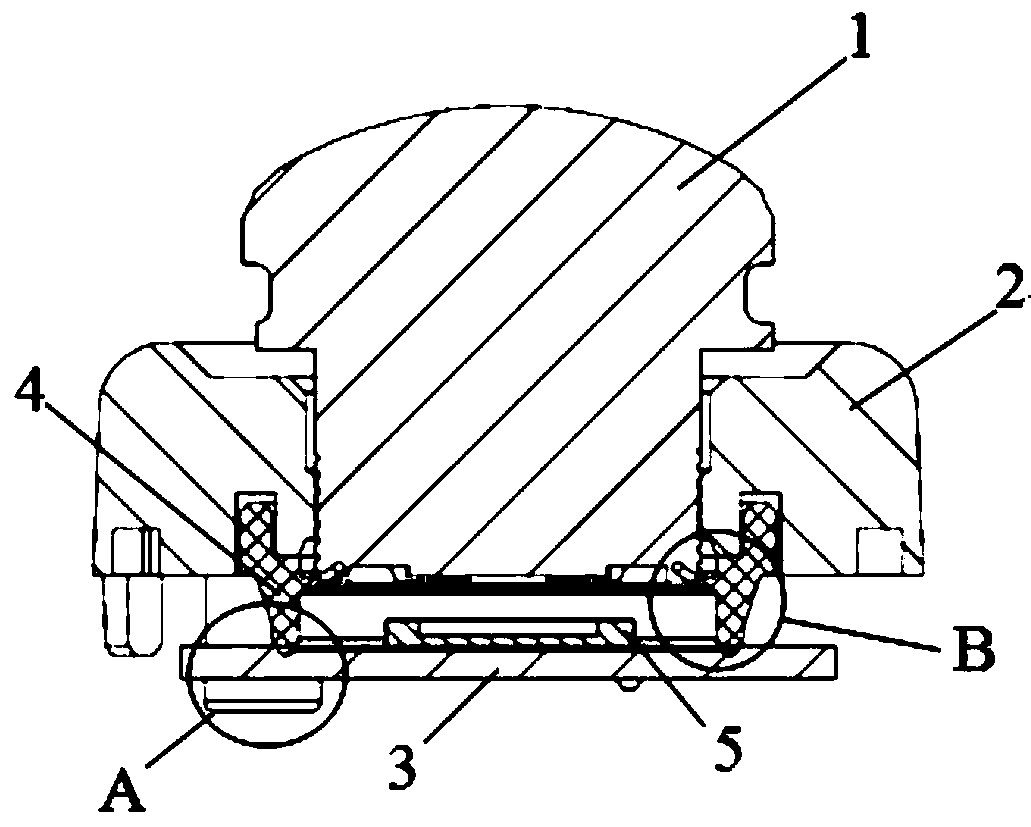

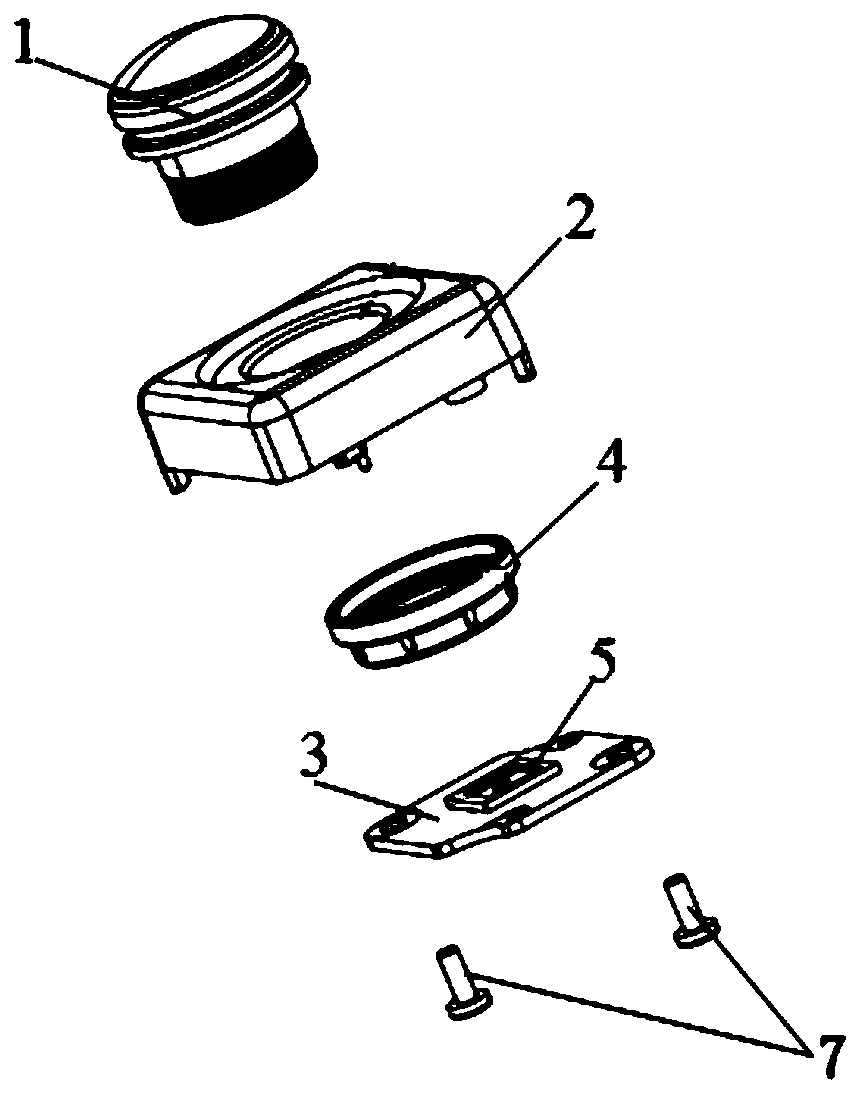

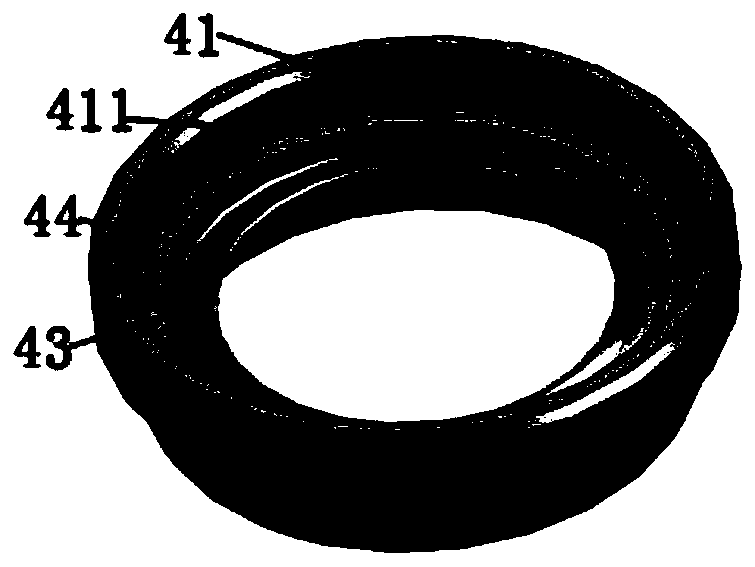

[0043] combine Figure 1-Figure 5 As shown, according to the first embodiment of the present invention, the circuit board 3 is provided with a first image sensor 5 . In this embodiment, the second part 42 of the sealing ring 4 is sealingly matched with the circuit board 3, and the matching part is located at the periphery of the first image sensor 5, that is, it can be understood that the second part 42 of the sealing ring 4 connects the first image sensor 5 is surrounded and arranged to isolate the first image sensor 5 from other electronic components on the circuit board 3 . The front housing 2 is arranged close to the first part 41 of the sealing ring 4, and the lower end of the first part 41 is provided with an annular crimping flange 411. The upper surface of the crimping flange 411 is a plane, and the front housing 2 is crimped on the On the upper surface of the crimp flange 411 . The third part 43 of the sealing ring 4 is sealingly matched with the lens 1, and the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com