Automatic control catheter tip forming mold

A technology for forming molds and catheter tips, applied in the field of medical devices, can solve the problems of hidden dangers in product stability, low efficiency, uneven heating of molds, etc., to ensure production stability, fast heating efficiency, and easy mold replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

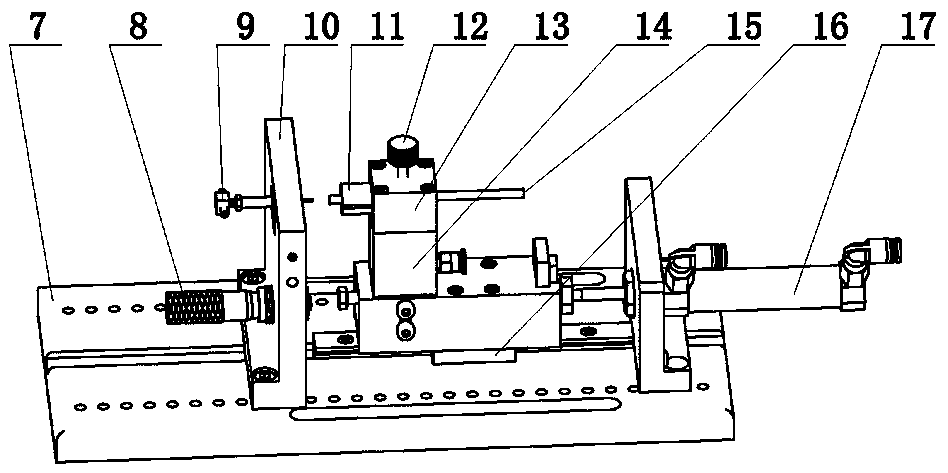

[0020] The present invention comprises base 7, is characterized in that: base 7 is provided with mold base 10, and mold base 10 is provided with molding die assembly 9; One side of base 7 corresponding to molding die assembly 9 is provided with motion unit 5, motion unit 5 is provided with a conduit clamping unit corresponding to the molding die assembly 9 .

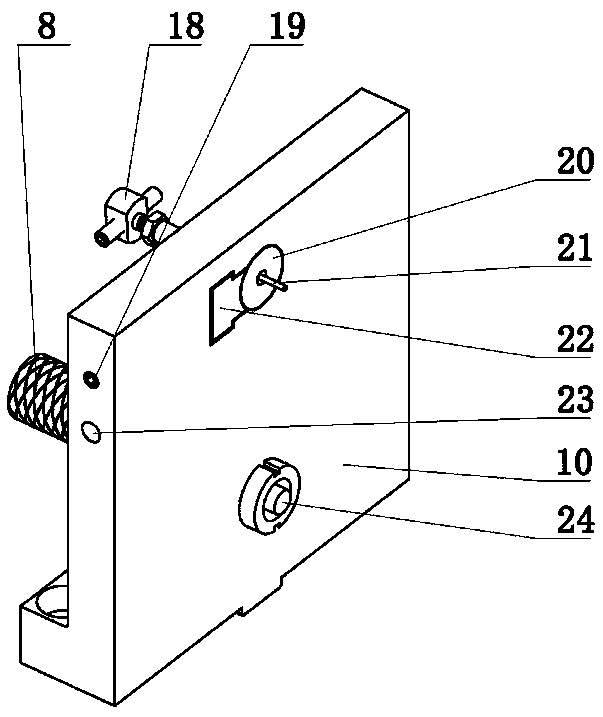

[0021] As a preferred solution of the present invention, the mold base 10 is provided with a water cooling passage 23 for the forming mold assembly 9 .

[0022] As another preferred solution of the present invention, a limiting device is provided on the mold seat 10 corresponding to the moving unit 5 .

[0023] The limiting device includes a micrometer 8 arranged on the mold base 10 , and the tip 24 of the micrometer 8 passes through the mold base 10 and corresponds to the moving unit 5 .

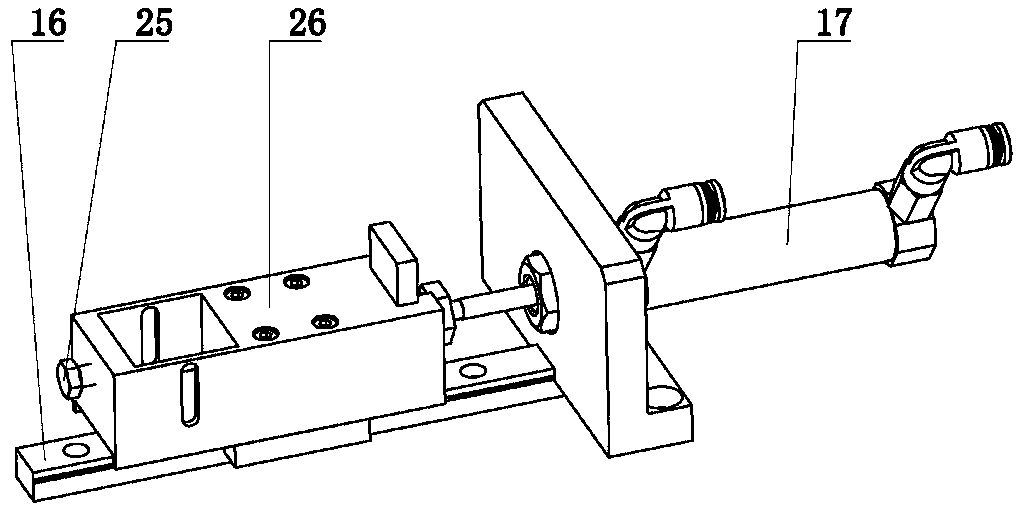

[0024] The movement unit 5 includes a telescopic cylinder 17 arranged on the base 7, the telescopic cylinder 17 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com