Borosilicate glass article with low boron content

A technology for borosilicate glass and glass products, applied in the field of borosilicate glass products, can solve the problems of inability to temper, expensive to manufacture, high melting temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

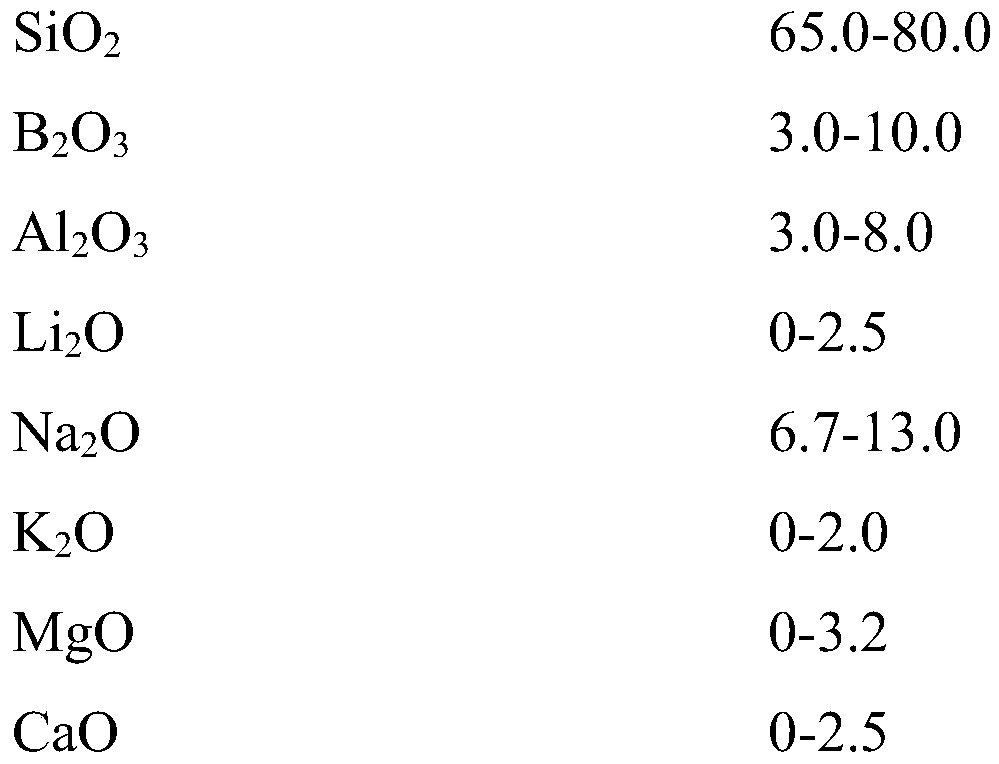

Method used

Image

Examples

Embodiment Construction

[0111] Many processes for producing borosilicate glass are known to those skilled in the art from the prior art. In one embodiment, conventional prior art fabrication processes may be used. Since the quality of a glass product can be determined not only by the selected glass composition and intended use, but also by the manufacturing process used for the glass product, it is advisable to choose an appropriate manufacturing process.

[0112] It is well known that glasses with a tendency to crystallize cannot be produced using stretching processes because they crystallize too quickly for this stretching process. In one embodiment, at a liquidus temperature and a glass viscosity of 10 6.5-7.0 Within the temperature range of the temperature limit at dPa.s, the crystallization rate of the glass should not exceed the limit of 0.1 μm / min. The liquidus temperature is the temperature above which the material completely melts. In practice, the liquidus temperature is the lowest tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com