Concrete containing high-activity slag powder and preparation method thereof

A slag powder, high activity technology, applied in the field of concrete, to achieve high lubricating effect, accelerate early hydration speed, and improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: A kind of concrete containing highly active slag powder, each component and its corresponding weight parts are as shown in Table 1 and Table 2, and are prepared by the following steps:

[0050] Step 1, select high-quality slag of corresponding parts by weight, add grinding aids of corresponding parts by weight, put it into a ball mill and grind at a speed of 120r / min to obtain a specific surface area of 500m 2 / kg of slag powder; put potassium sulfate, slaked lime and gypsum into a ball mill for grinding, and then mix with slag powder evenly to obtain highly active slag powder

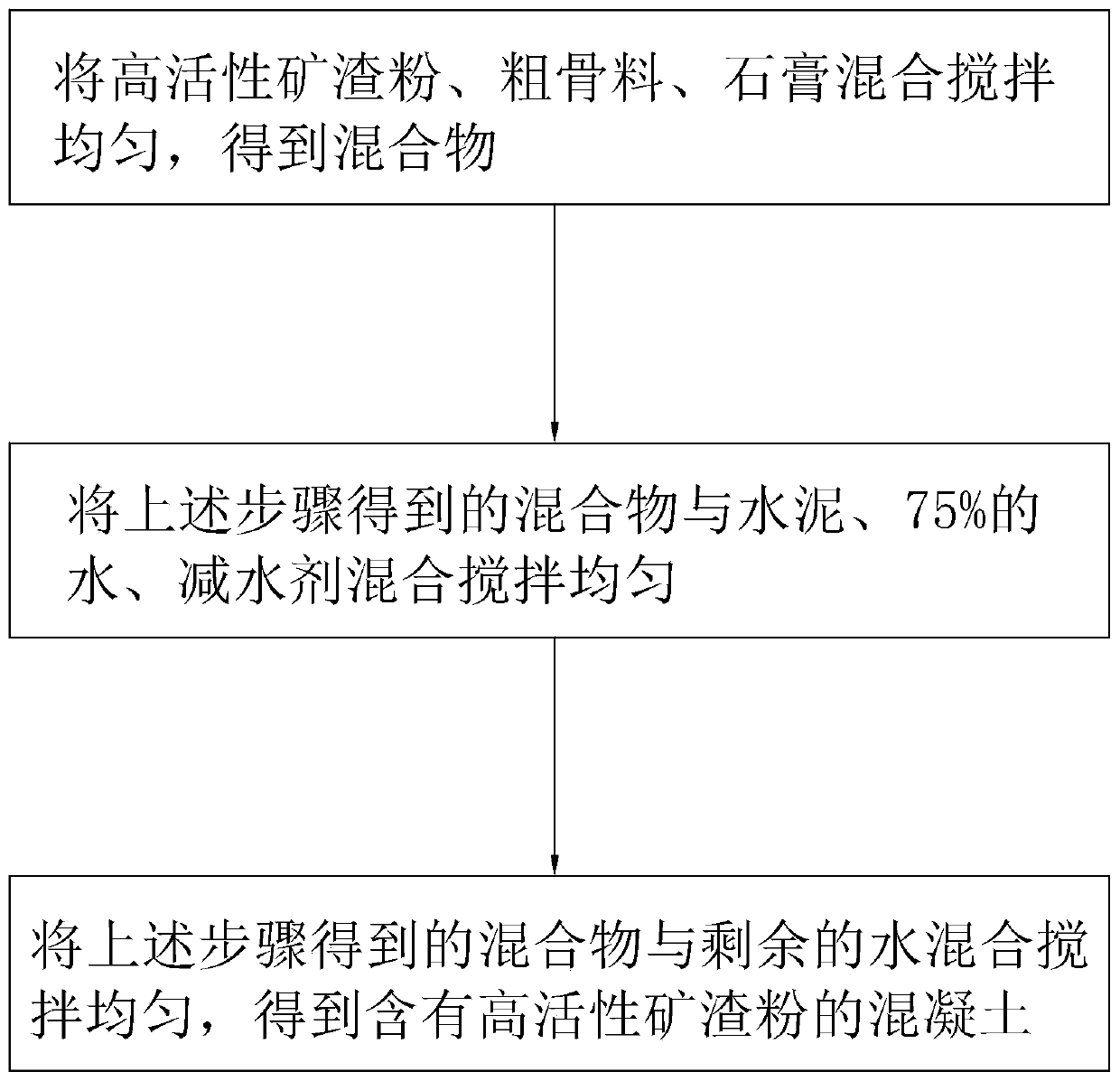

[0051]Step 2, mixing and stirring the highly active slag powder, coarse aggregate and gypsum evenly to obtain a mixture;

[0052] Step 3, mixing and stirring the mixture obtained in the above steps with cement, 75% water, and water reducing agent;

[0053] Step 4, mixing and stirring the mixture obtained in the above steps with the remaining water evenly to obtain concrete conta...

Embodiment 2-6

[0055] Example 2-6: A concrete containing highly active slag powder. The difference from Example 1 is that the components and their corresponding parts by weight are shown in Table 1 and Table 2.

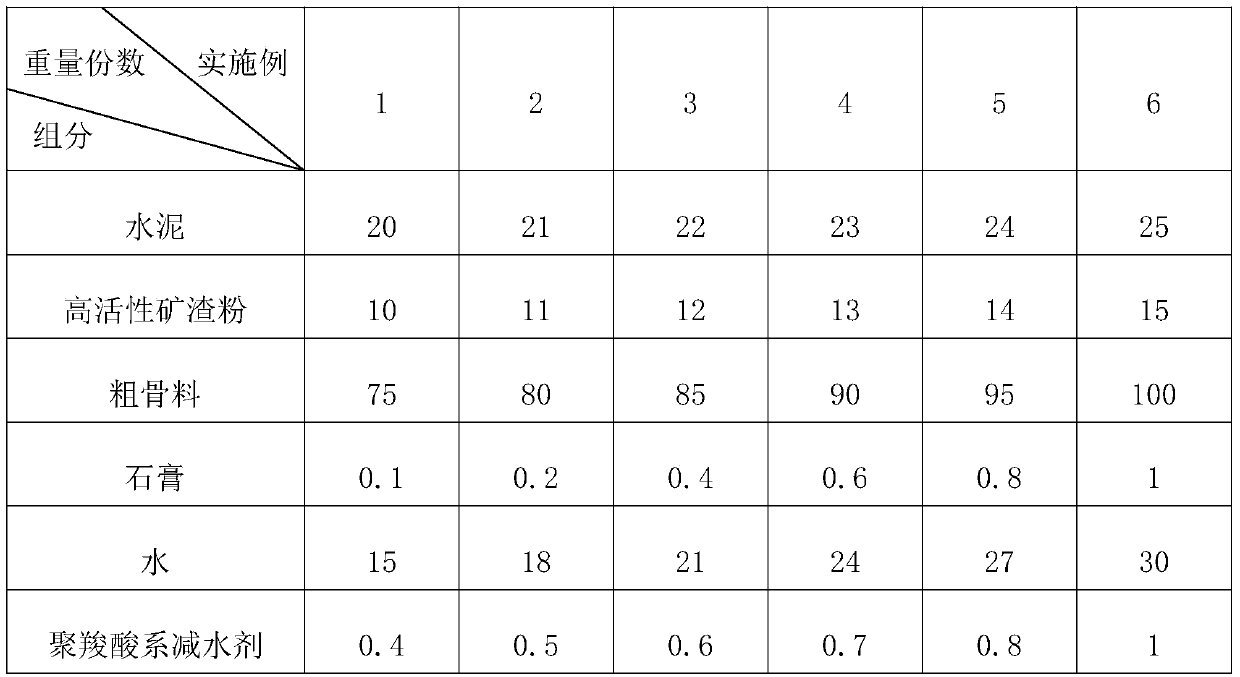

[0056] Each component and parts by weight thereof in table 1 embodiment 1-6

[0057]

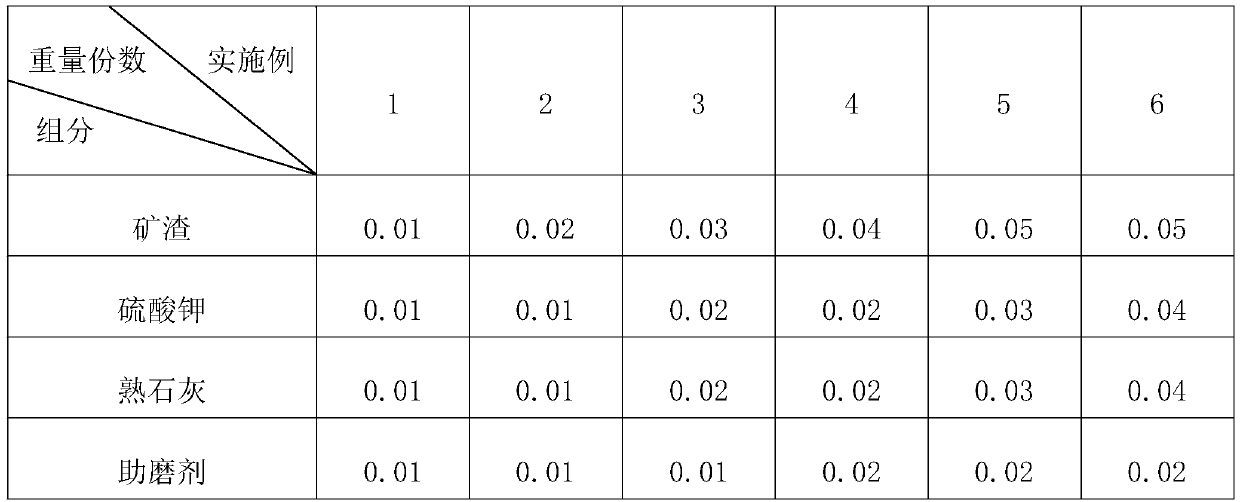

[0058] Each component of high activity slag powder and its weight parts in the embodiment 1-6 of table 2

[0059]

Embodiment 7

[0060] Embodiment 7: A kind of concrete containing highly active slag powder, the difference from embodiment 1 is that 1 part of fly ash is added in step 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com