Compounds, photoelectric conversion devices and electronic devices

A photoelectric conversion and compound technology, applied in the field of organic materials, can solve the problems of performance degradation of light-emitting devices, increase in operating voltage, decrease in luminous efficiency, etc., and achieve the effect of improving the molecular weight of materials, low driving voltage, and enhancing injection and transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

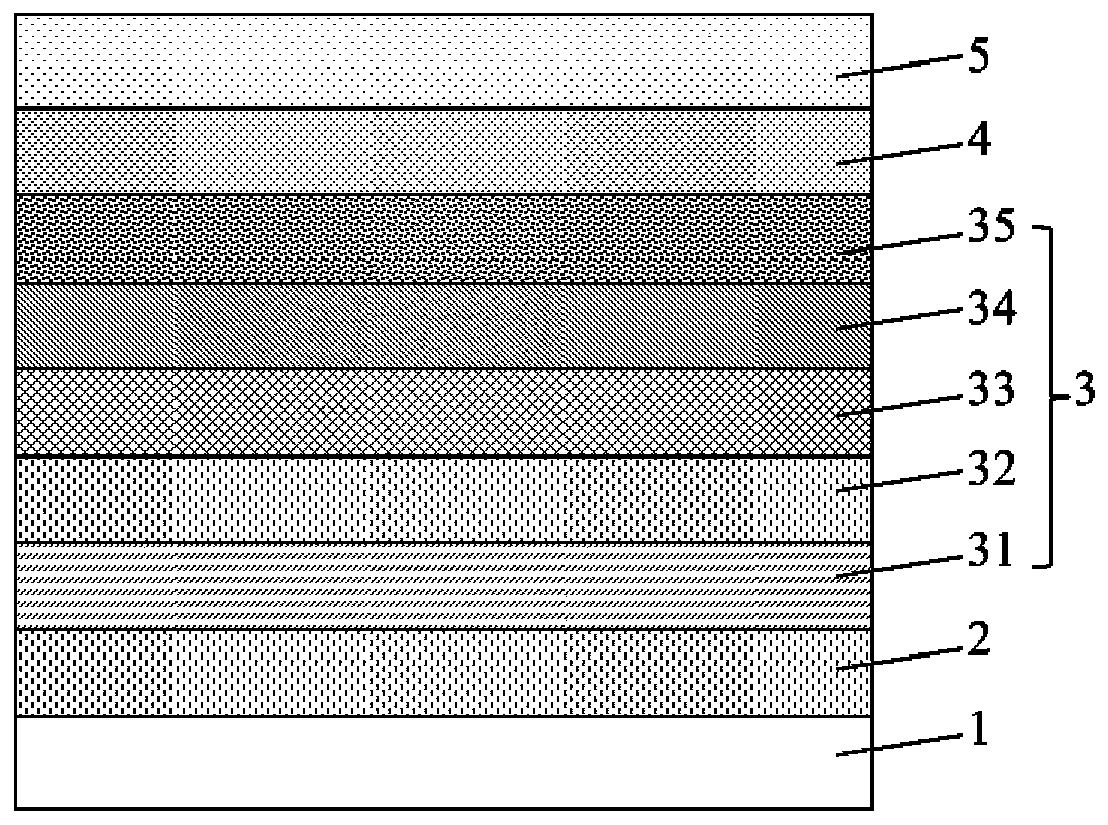

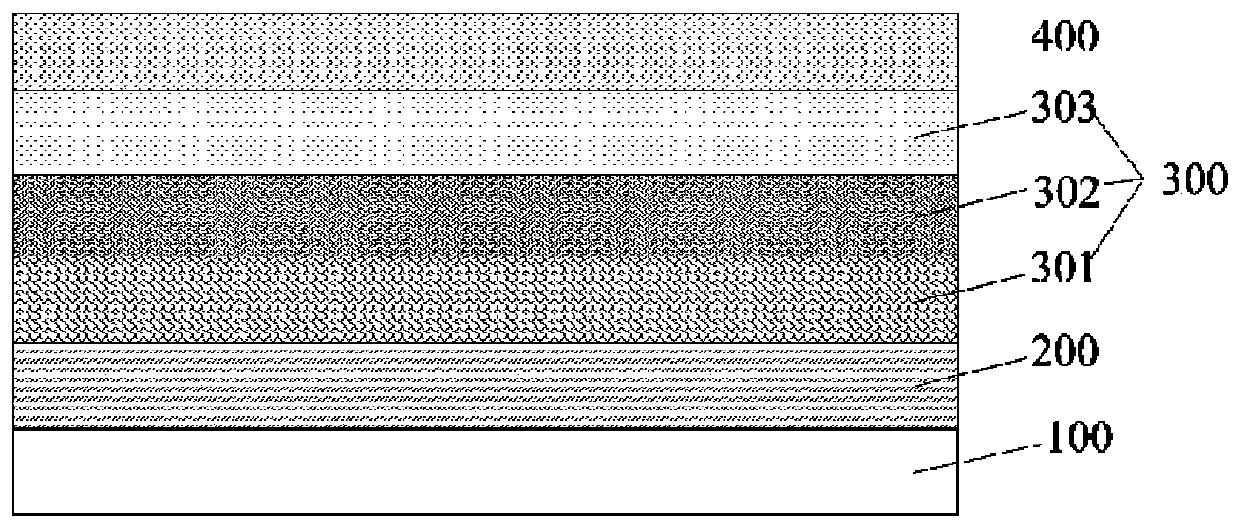

[0201] Anode 1 was prepared by the following process: the thickness of ITO was The ITO substrate (manufactured by Corning) was cut into a size of 40mm (length) × 40mm (width) × 0.7mm (thickness), and it was prepared into a pattern with a cathode 5 overlapping area, an anode 1 and an insulating layer by using a photolithography process. Top emission experimental substrate, using ultraviolet ozone and O 2 :N 2 Plasma was used for surface treatment to increase the work function of the anode 1 (experimental substrate) and to clean the experimental substrate.

[0202] Vacuum-deposit m-MTDATA (4,4',4"-tris(N-3-methylphenyl-N-phenylamino)triphenylamine) on the experimental substrate (anode 1) to form a thickness of The hole injection layer 2 (HIL), and on the hole injection layer 2 vacuum evaporated NPB (N,N'-diphenyl-N,N'-(1-naphthyl)-1,1'-bi benzene-4,4'-diamine) to form a thickness of The hole transport layer 31 (HTL).

[0203] Evaporate TCTA (4,4',4 "-tris(carbazol-9-yl) ...

Embodiment 2~17

[0208] An organic electroluminescent device was fabricated by the same method as in Example 1 except that the compounds shown in Table 1 were each used in forming the electron transport layer 35 (ETL).

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap