Strengthened coated rock wool Insulation board

A thermal insulation board and rock wool technology, applied in thermal insulation, climate change adaptation, building components, etc., can solve the problems of easy delamination and falling off of the middle rock wool interlayer, heavy weight of external wall insulation boards, low tensile and flexural strength, etc. , to achieve the effect of avoiding cracking, light weight, and solving delamination and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

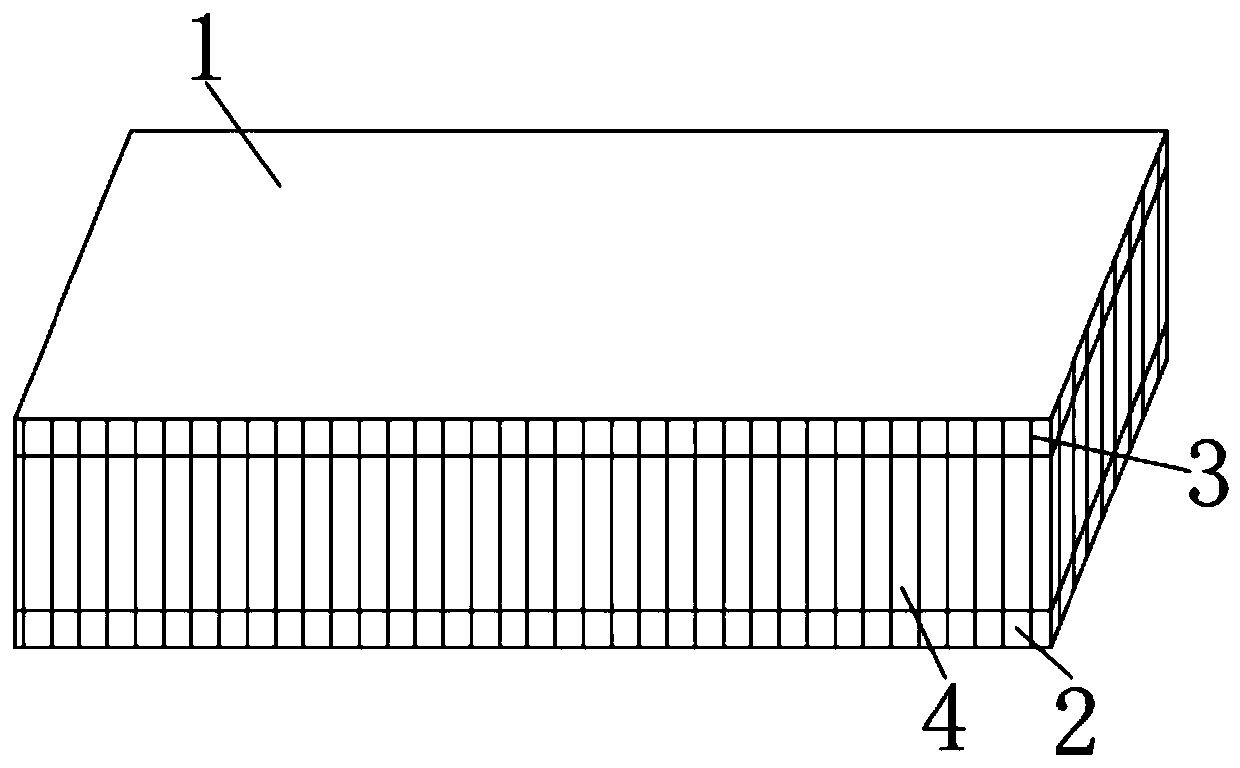

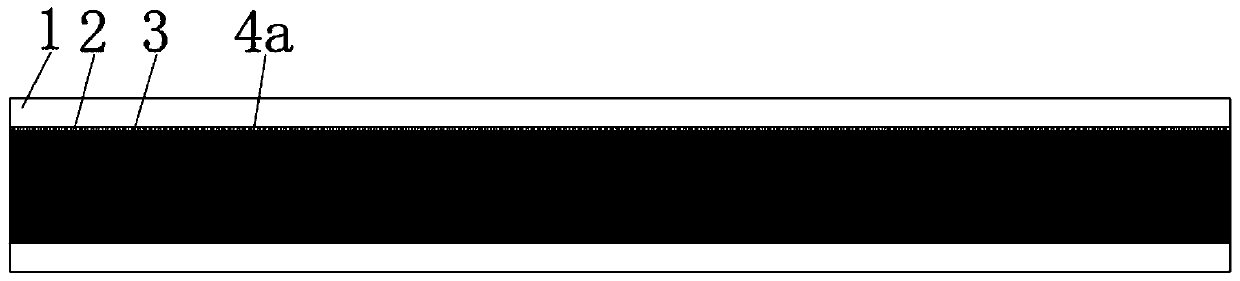

[0022] Example 1-1: The lower side of the plastering mortar layer 1 is laminated with an alkali-resistant fiber mesh 2, and the alkali-resistant fiber mesh 2 and the vertical thread rock wool 4a are sewn with an alkali-resistant sewing thread 3, and the alkali-resistant fiber mesh The lower side of the cloth 2 is pressed with the vertical thread rock wool 4a, and the vertical thread rock wool 4a is located inside the insulation board. By assembling the rock wool 4 of a certain thickness into the vertical thread rock wool 4a, the vertical thread rock wool 4a is placed on the upper and lower sides. Lay alkali-resistant fiber mesh cloth 2 on one surface, sew alkali-resistant fiber mesh cloth 2 and vertical thread rock wool 4a together with alkali-resistant sewing thread 3, spray the surface with plastering glue layer 1, and make a cladding surface after curing Rock wool insulation board has high tensile and flexural strength, good fire resistance, non-combustibility in case of fir...

Embodiment 1-2

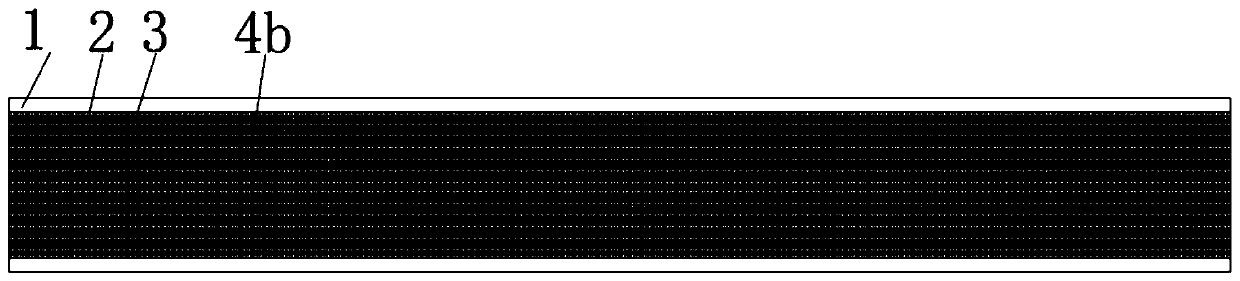

[0023] Example 1-2: The lower side of the plastering mortar layer 1 is laminated with an alkali-resistant fiber mesh 2, and the alkali-resistant fiber mesh 2 and the horizontal thread rock wool 4b are sewn with an alkali-resistant sewing thread 3, and the alkali-resistant fiber mesh The lower side of the cloth 2 is pressed with the horizontal thread rock wool 4b, and the horizontal thread rock wool 4b is located inside the insulation board. By assembling the rock wool 4 of a certain thickness into the vertical thread rock wool 4a, the upper and lower sides of the vertical thread rock wool 4a Lay alkali-resistant fiber mesh cloth 2 on one surface, sew alkali-resistant fiber mesh cloth 2 and vertical thread rock wool 4a together with alkali-resistant sewing thread 3, spray the surface with plastering glue layer 1, and make a cladding surface after curing Rock wool insulation board has high compressive, tensile and flexural strength, is not easy to crack, and has a long service li...

Embodiment 2-1

[0024] Example 2-1: The upper end of the alkali-resistant fiber mesh cloth 2 is pressed on the lower side of the top plastering mortar layer 1b, and the bottom plastering mortar layer 1a, the alkali-resistant fiber mesh cloth 2 and the vertical thread rock wool 4a are sewn with an anti-alkali Alkali sewing thread 3, the lower side of the alkali-resistant fiber mesh cloth 2 is pressed with the bottom plastering mortar layer 1a, and the lower side of the bottom plastering mortar layer 1a is pressed with vertical thread rock wool 4a, and the vertical thread rock wool 4a is located in the insulation Inside the board, the rock wool 4 of a certain thickness is assembled into the vertical thread rock wool 4a, and the bottom plastering mortar layer 1a is respectively covered on the upper and lower sides of the vertical thread rock wool 4a, and then the bottom plastering mortar layer 1a is covered again. Immediately cover the alkali-resistant fiber mesh 2, and use the horizontal alkali-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com