Piston with double cooling oil cavities and assembly method of piston

A technology of cooling oil cavity and double cooling, applied in the direction of piston, metal processing, engine components, etc., can solve the problems of the danger of pulling the cylinder, difficult to detect the welding quality of the welding seam, affecting the cooling effect, etc., to increase the cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

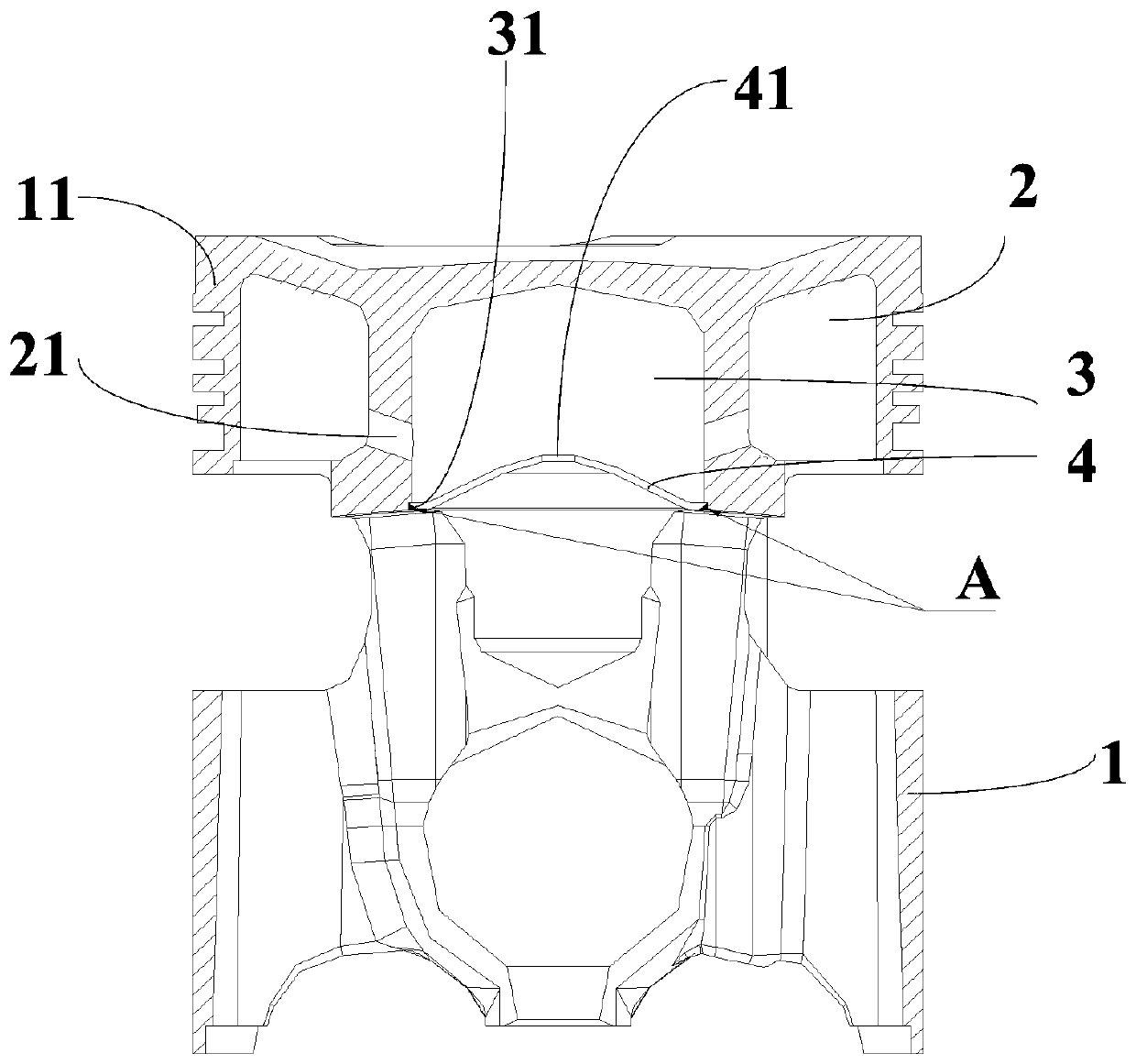

[0039] The present invention provides a piston with double cooling oil chambers, see attached Figure 1-10 ,include:

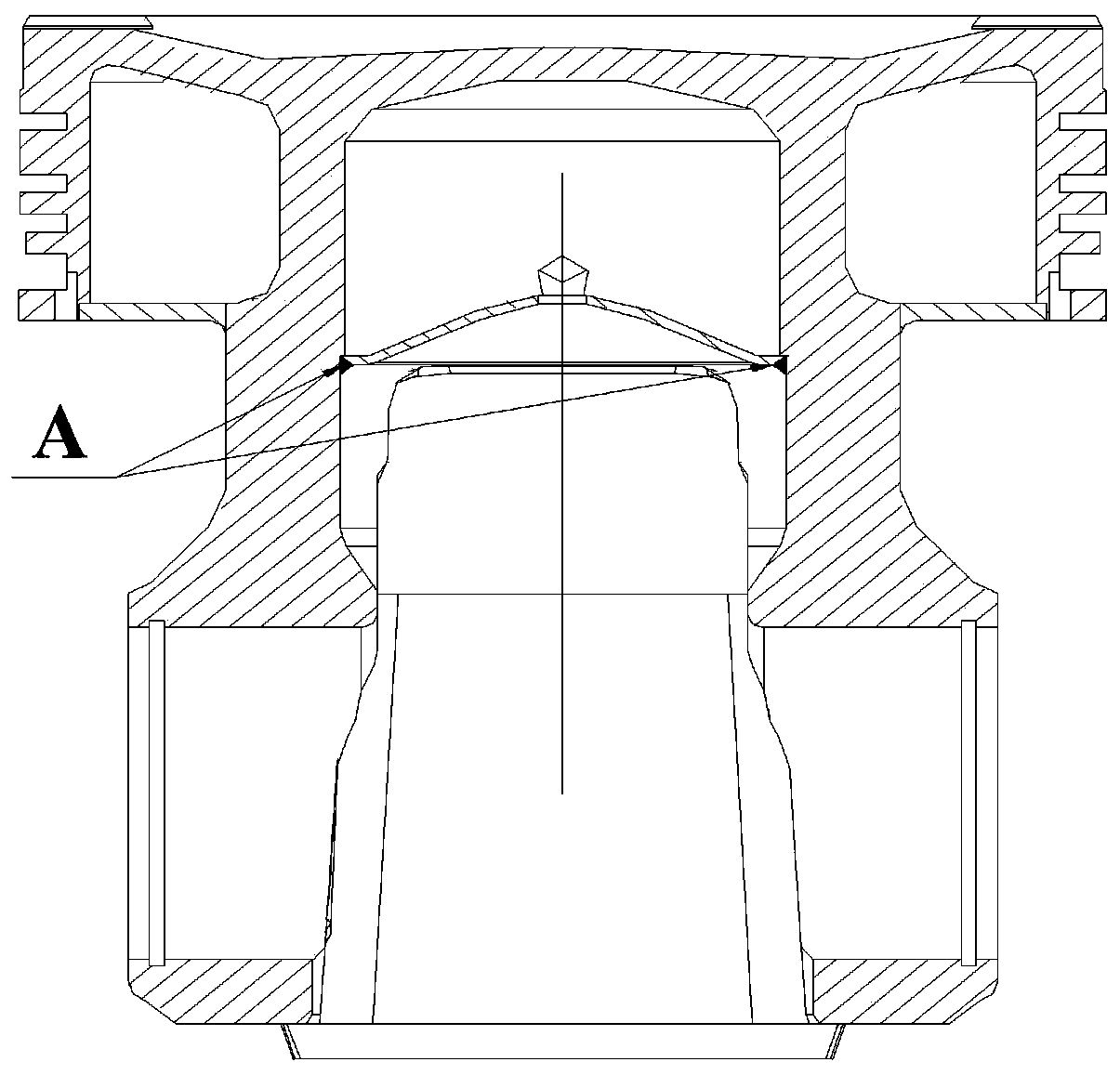

[0040] The piston body 1, the head of the piston body 1 is provided with a first cooling oil chamber 2 and a second cooling oil chamber groove 3 communicating with each other; the opening direction of the second cooling oil chamber groove 3 faces the direction of the small end of the connecting rod;

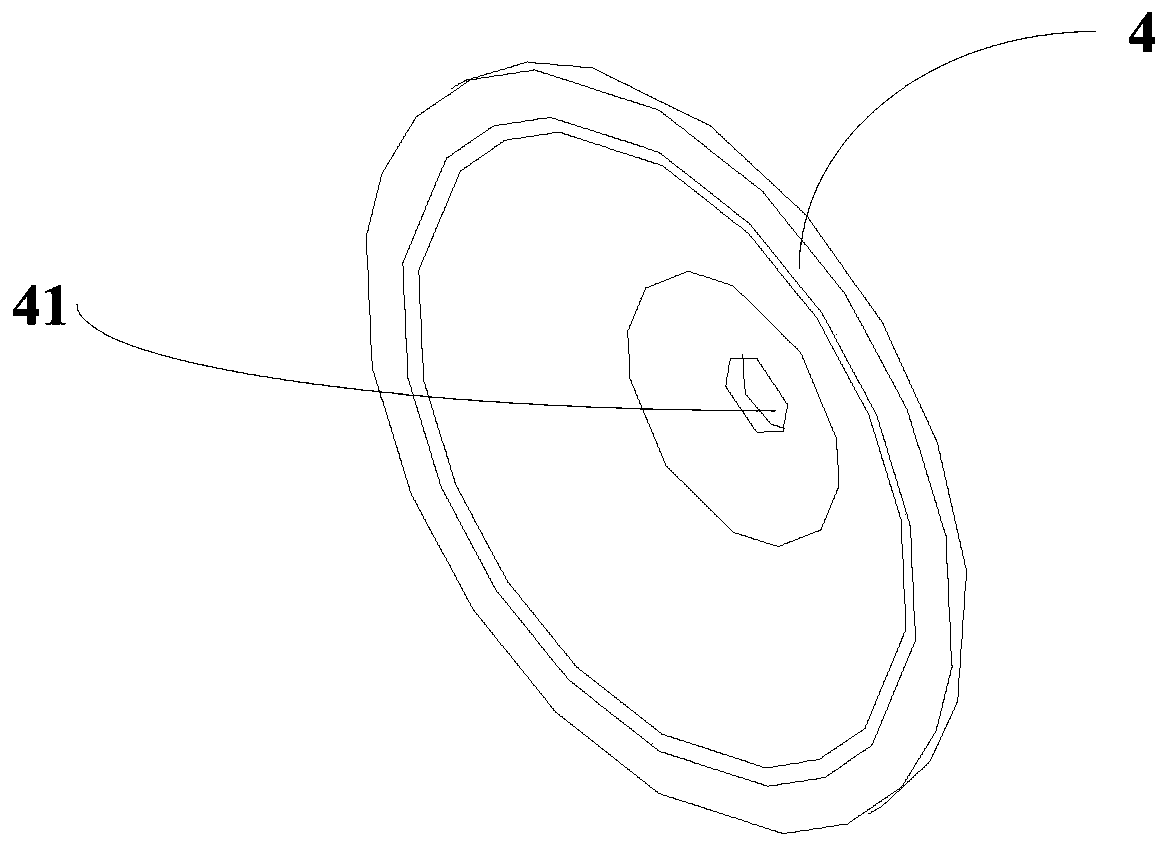

[0041] The steel sheet 4, the steel sheet 4 is used to close the opening of the second cooling oil chamber groove 3 to form the second cooling oil chamber, and there is no welding seam in the second cooling oil chamber, and the steel sheet 4 has an oil drain hole 41 .

[0042] The disclosure of the present invention provides a piston with double cooling oil chambers. Firstly, because the steel sheet 4 is used to close the opening of the second cooling oil chamber groove 3, there is no weld seam in the formed second cooling oil chamber, which solves the problem of...

Embodiment 2

[0044] The invention provides a piston with double cooling oil chambers, see the attached figure 1 , the shape of the inner chamber of the second cooling oil chamber groove 3 is the same as that of the piston combustion chamber, and its opening is provided with a mounting groove 31, and the steel sheet 4 is installed in the mounting groove 31 and connected with the mounting groove 31 as a whole. The shape of the inner cavity of the second cooling oil cavity groove 3 is consistent with the shape of the combustion chamber, and the wall thickness is kept uniform, which is beneficial to heat transfer. The distance from the combustion chamber to the inner cavity is guaranteed to be 5-8mm to ensure sufficient supporting area.

Embodiment 3

[0046] The invention provides a piston with double cooling oil chambers. The inner cavity shape of the second cooling oil chamber groove 3 is the same as that of the piston combustion chamber, and a mounting groove 31 is opened at the opening, and the steel sheet 4 is installed behind the mounting groove 31 It is integrated with the installation groove 31. The installation groove 31 is an annular groove, the diameter of the top of the ring groove is smaller than the diameter of the bottom, and the diameter of the top of the ring groove is 1-2mm smaller than the diameter of the steel sheet 4 . That is, the upper part of the installation groove 31 protrudes from the lower part to form a step, and the step is conducive to blocking the top of the steel sheet 4, and is convenient for connecting between the top of the steel sheet 4 and the installation groove 31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com