Integrated cooling device for hydraulic transmission locomotive

A cooling device and hydraulic transmission technology, applied in the direction of fluid pressure actuation device, engine components, engine lubrication, etc., can solve the problems of high cost, unsafe, complicated, etc., and achieve simple, orderly and simplified pipeline layout. The effect of cooling device arrangement and simplified design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

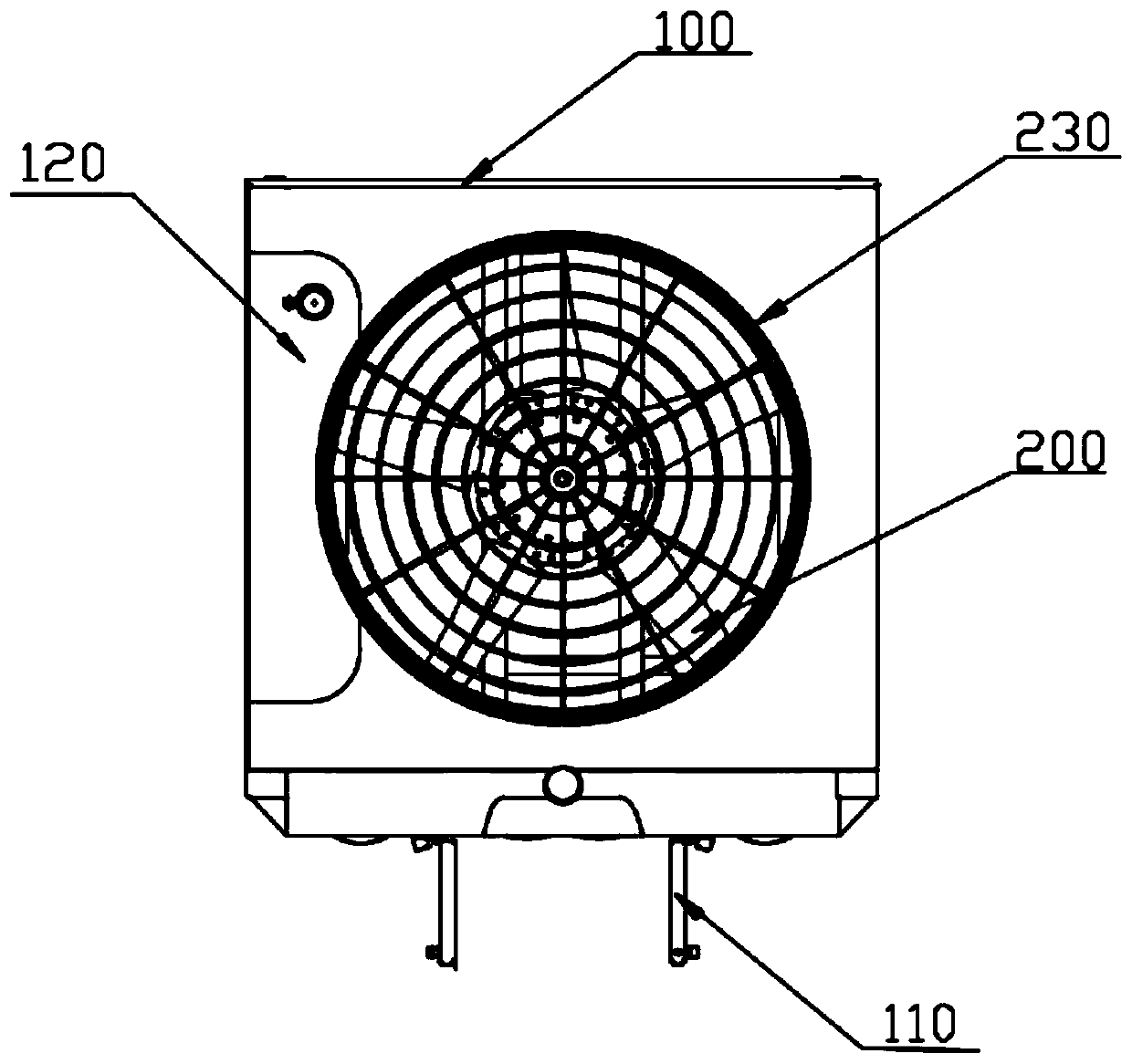

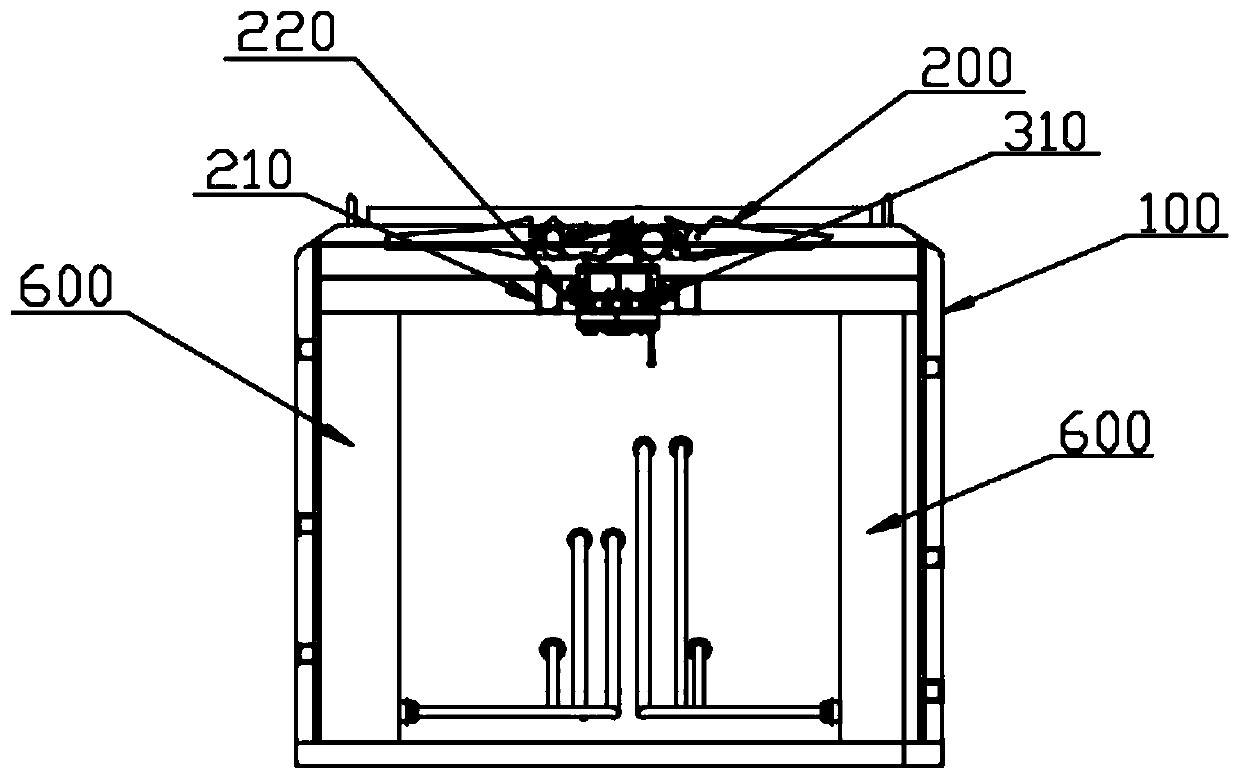

[0040] The embodiment is basically as figure 1 and figure 2 As shown: this embodiment provides an integrated cooling device for a hydraulic transmission locomotive, including a cooling housing 100, a cooling fan 200, and a fan mounting plate 220. One side of the cooling housing 100 has an inspection door 110, which can be accessed through the inspection door. The door 110 checks its internal cooling device; and on the top of the cooling shell 100, there is a storage room 120 for containing the expansion tank, which can effectively integrate the expansion into the cooling shell 100 to avoid additional storage space, and can ensure that the expansion tank is installed Requirements at heights. A mounting base 210 is fixedly installed on the upper middle of the cooling housing 100, and the mounting base 210 is fixed on the inner wall of the cooling housing 100 through a detachable connection with bolts; and a detachable fan mounting plate 220 is installed on the mounting base 21...

Embodiment 2

[0047] Embodiment 2 is basically the same as Embodiment 1, the difference is: please combine Figure 4 and Figure 6 As shown, this embodiment can provide a combination of four different heat sources for air, water, engine oil and transmission oil, specifically including air inlet and outlet, cooling water inlet and outlet, engine oil inlet and outlet, transmission oil inlet and outlet, and hydrostatic oil inlet and outlet ; Thereby blocking unnecessary hydrostatic oil inlet and outlet, correspondingly distributing the heat dissipation single section inside the cooling housing 100 into four radiators 600, the four radiators 600 are specifically cooling water radiators 620 and air radiators 610 , engine oil radiator 630 and transmission oil radiator 640, the inlet and outlet 400 of the four heat sources are respectively connected to the corresponding radiator 600 through pipelines, and a cooling device is realized through the ancient official road to meet the heat dissipation r...

Embodiment 3

[0049] Embodiment 3 is basically the same as Embodiment 1, the difference is: please refer to Figure 7 As shown, the drive mechanism 300 provided in this embodiment is a hydrostatic motor 320 as a power element, and the installation requirements for the hydrostatic motor 320 to drive the cooling fan 200 are met by adjusting the fan mounting plate 220, specifically, the hydrostatic pump of the hydrostatic motor 320 322 is fixed on the fan mounting plate 220 by fixing parts such as lock nuts, and the output shaft of the hydrostatic pump 322 is connected to the rotating shaft of the cooling fan 200 by transmission. The specific driving method and control principle of the fan driven by the hydrostatic motor 320 are prior art For example, Chinese Patent Publication No. CN203114404U discloses a forklift engine cooling system with a hydrostatically driven fan, and the cooling fan 200 is driven by a hydrostatic motor 320 . However, in this embodiment, the detachable connection betwee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap