Microbial exhaust gas purification

A waste gas purification and microbial technology, which is applied in the direction of air quality improvement, chemical instruments and methods, combined devices, etc., can solve the problems of high cost and high energy consumption of waste gas treatment equipment, so as to improve the purification effect, strengthen the purification effect, reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

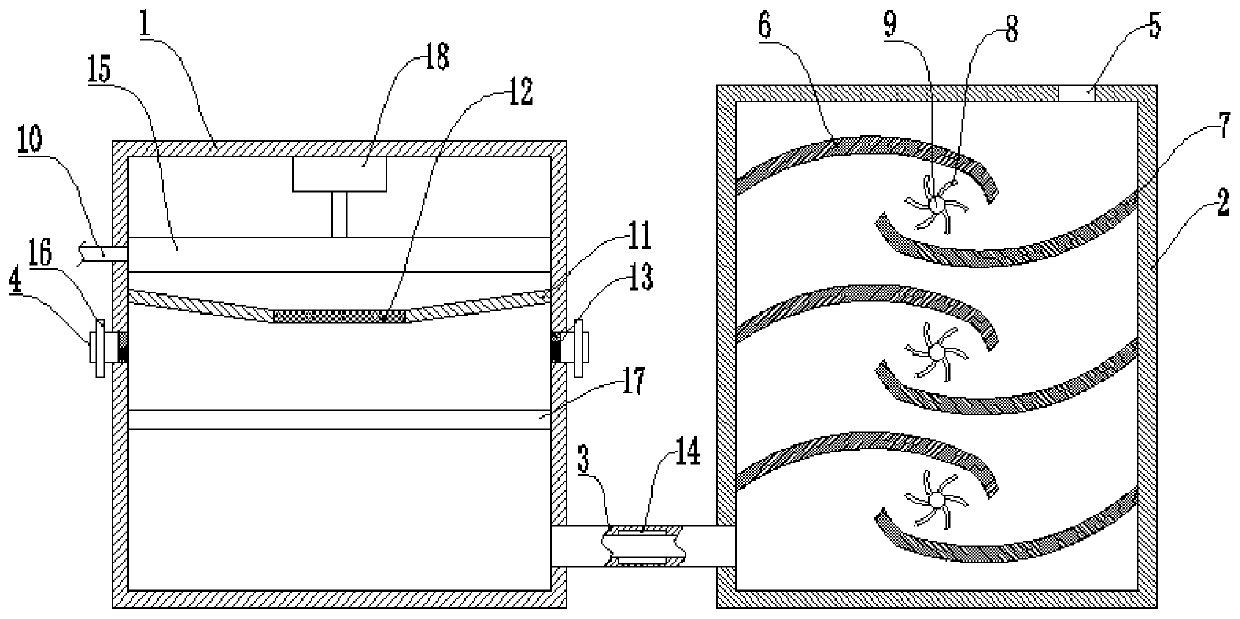

[0031] Basic as attached figure 1 Shown: purification of microbial waste gas, including dust suppression box 1 and degradation box 2, and pipeline 3 is fixedly connected between dust suppression box 1 and degradation box 2, and pipeline 3 connects dust suppression box 1 and degradation box 2, and the inner wall of pipeline 3 is set There is a heating wire 14; there is an inlet 4 on the dust suppression box 1, and there are two inlets 4, and the two inlets 4 are respectively located on both sides of the dust suppression box 1; a screen 13 is fixed in the inlet 4. The top of the degradation box 2 is provided with an outlet 5 .

[0032] The dust suppression box 1 is provided with a dust suppression mechanism for removing suspended particulate pollutants in the exhaust gas. The dust suppression mechanism includes a partition 11 fixed in the body of the dust suppression box 1 and a water inlet pipe 10 connected with the dust suppression box 1. The partition 11 is located at the wat...

Embodiment 2

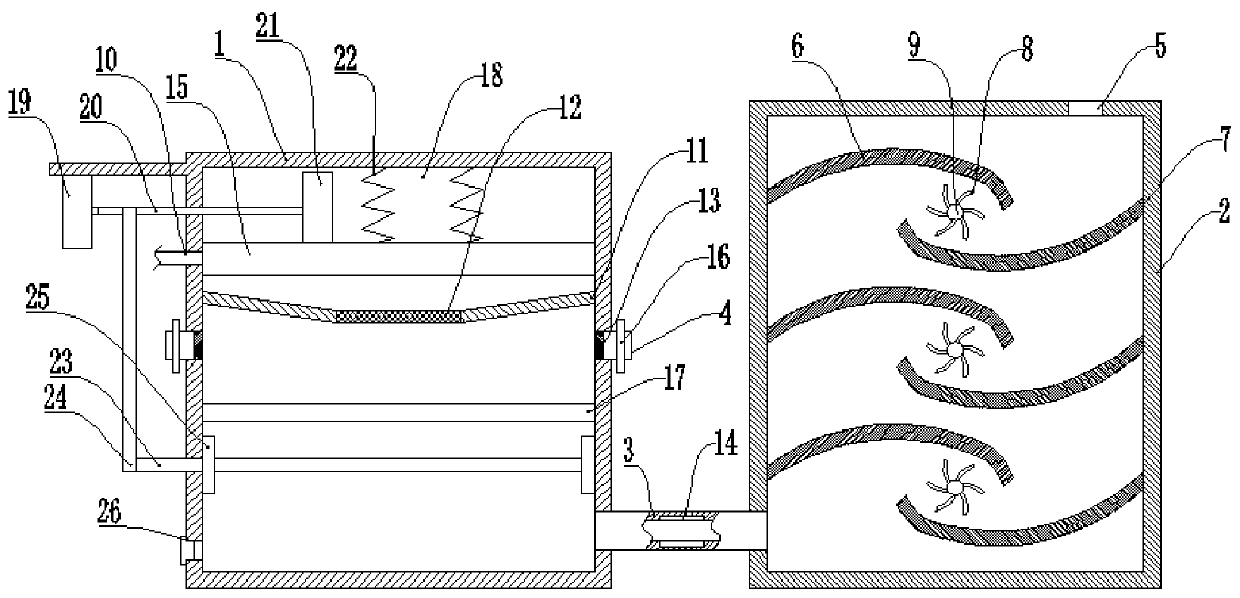

[0042] Basic as attached figure 2 As shown, the structure and implementation of Embodiment 2 are basically the same as Embodiment 1. The difference is that the power mechanism includes a motor 19 fixed to the outer wall of the dust suppression box 1 and a linkage shaft 20 connected in rotation with the dust suppression box 1. The shaft 20 is affixed to the output shaft of the motor 19, and the linkage shaft 20 is affixed with a cam 21 against the lifting plate 15, and the cam 21 is located above the lifting plate 15; a spring 22 is affixed between the lifting plate 15 and the dust box 1 .

[0043] A circular shaft 23 is rotatably connected to the dust suppression box 1, and the circular shaft 23 is located below the second one-way valve 17; a stretched belt 24 is sleeved between the circular shaft 23 and the linkage shaft 20, and the circular shaft 23 is provided with a dust-suppression valve. There are two sponge blocks 25 attached to the inner wall of the case 1, and there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com