Ship robot

A technology of robots and ships, which is applied in the field of robots, can solve problems such as incomplete cleaning and rust cleaning, and achieve the effect of improving the cleaning effect, smooth conversion, and strengthening the connection relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

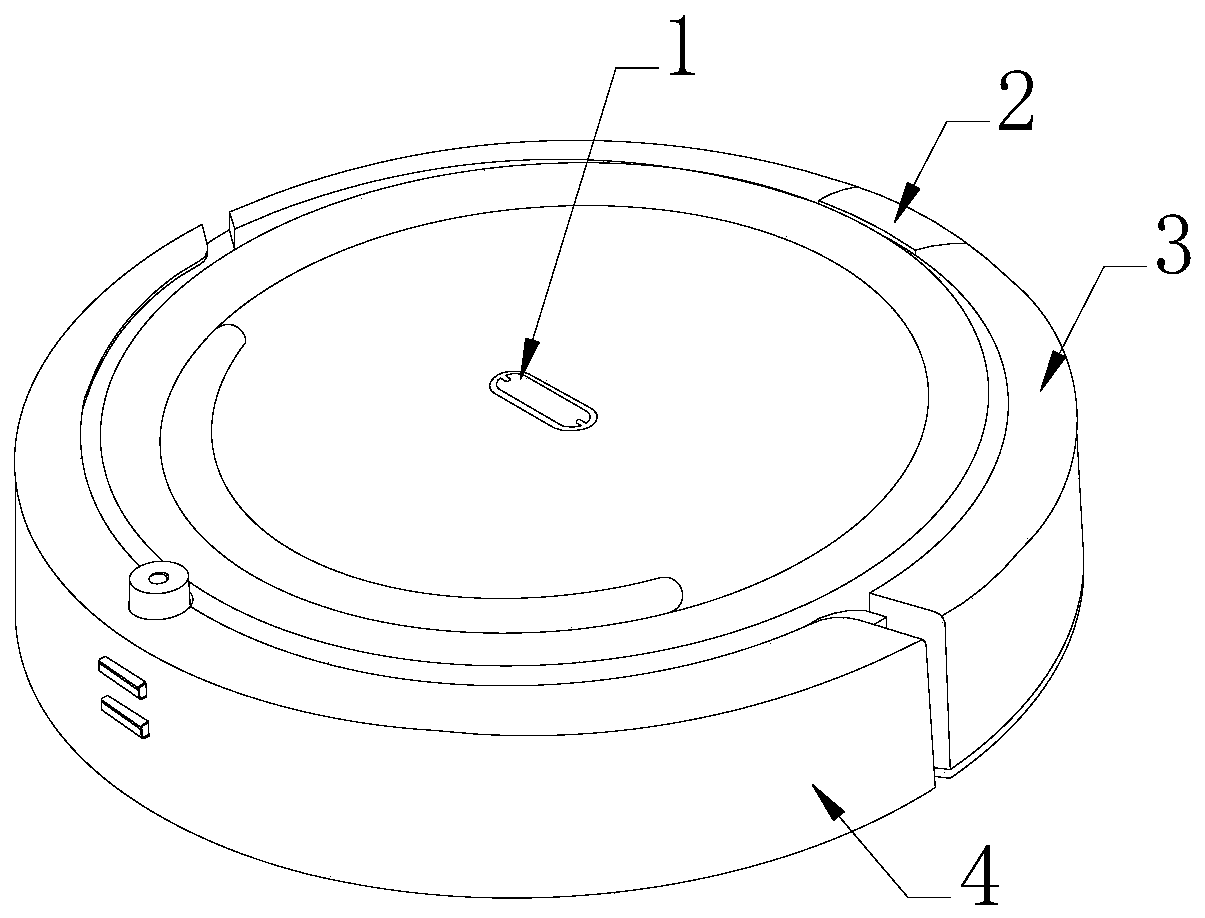

[0029] see Figure 1-Figure 6 , the present invention provides a ship robot, the structure of which includes a column cleaning structure 1, a hinge 2, a main body 3, and a casing 4. The column cleaning structure 1 is installed in the middle of the main body 3, and the main body 3 passes The hinge 2 is provided with a top cover, the main body 3 is a flat cylinder, and a semi-arc-shaped casing 4 is installed on the side of the main body 3 .

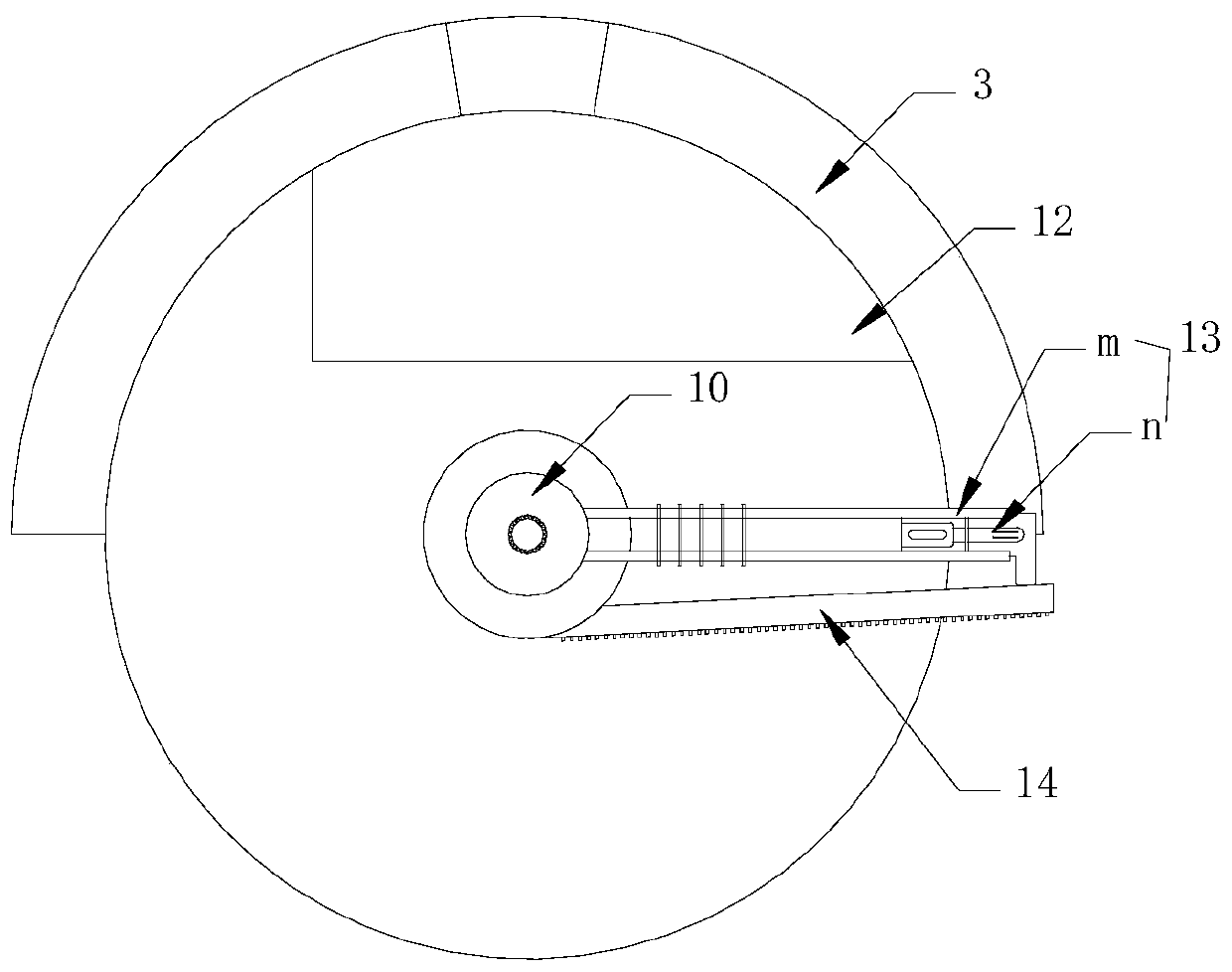

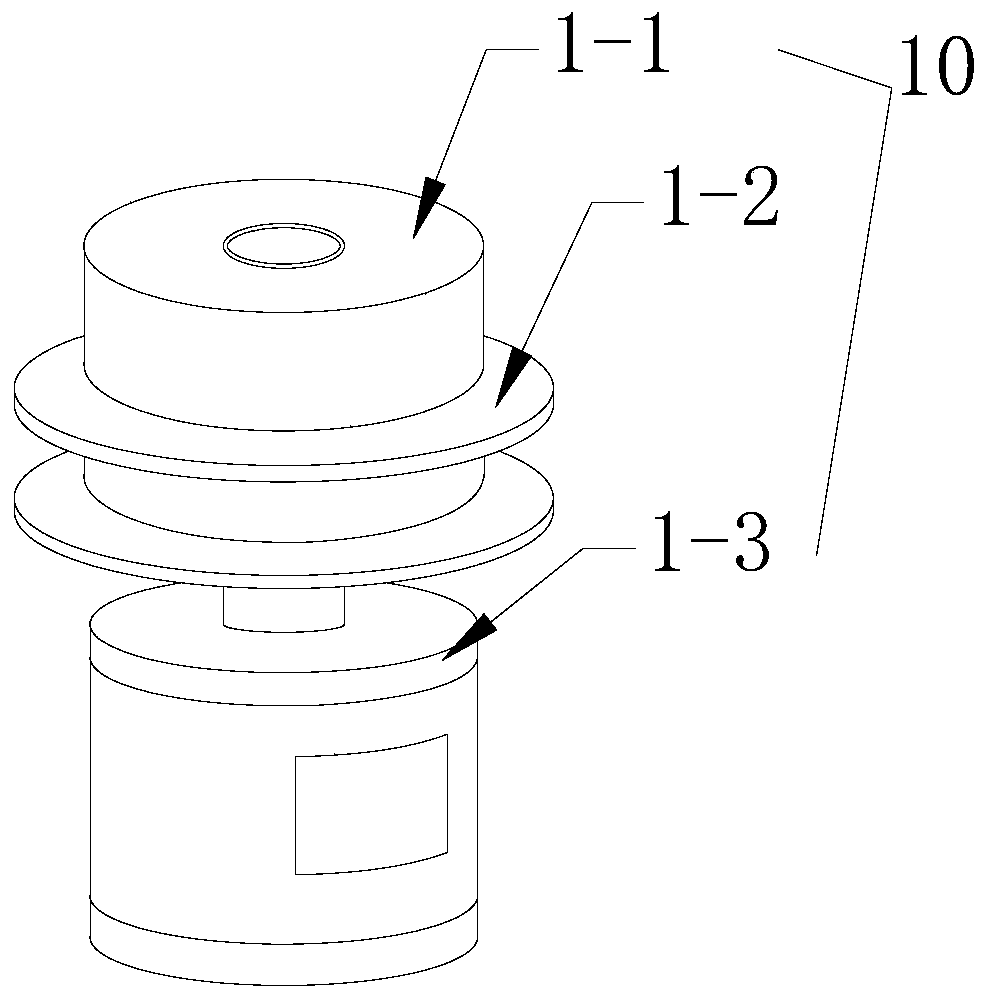

[0030] The column winding cleaning structure 1 is composed of an inner bottom plate 12, a driving lever 13, a take-up coil 14, and a column winding device 10. A column winding device 10 is installed in the middle of the inner bottom plate 12, and the upper and lower ends of the column winding device 10 The driving lever 13 and the take-up roll 14 are installed respectively, and the said take-up roll 14 is in contact with the end of the driving lever 13 .

[0031] The driving lever 13 is provided with a support m and a shifting block n, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com