A pottery clay mud refining device for making ceramics

A mud-making and clay-making technology, applied in the field of ceramic manufacturing, can solve the problems of low efficiency of impurity removal, low quality of mud-making, and affecting production efficiency, so as to improve work efficiency, reduce labor, and realize the effect of fully automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

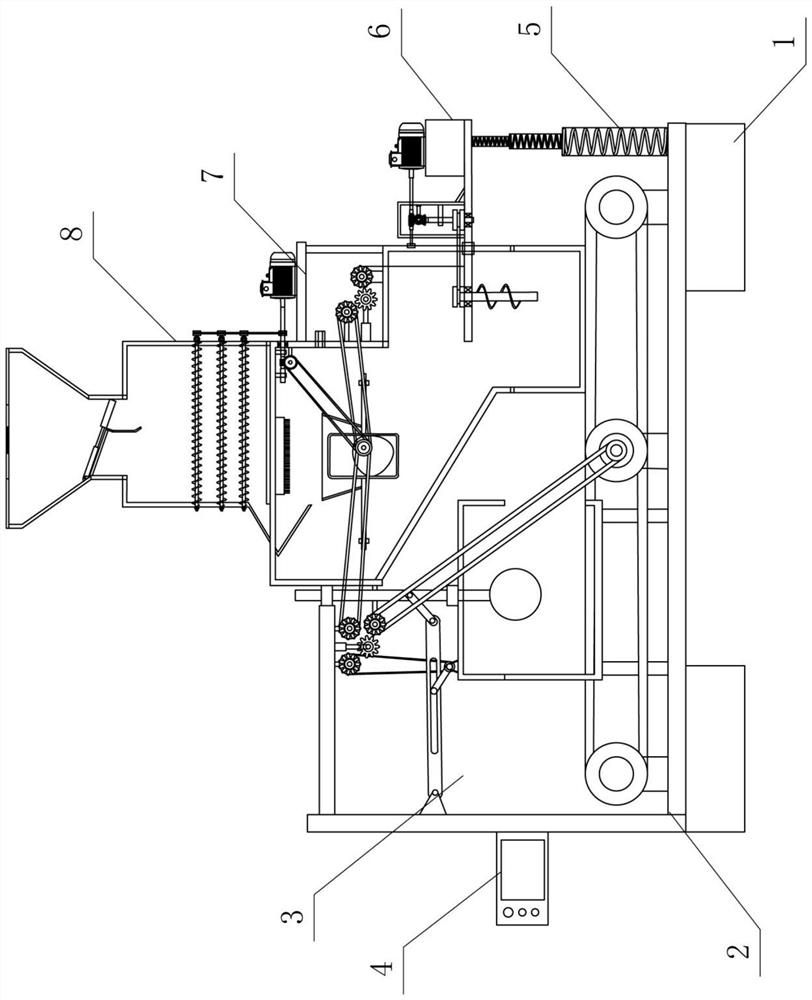

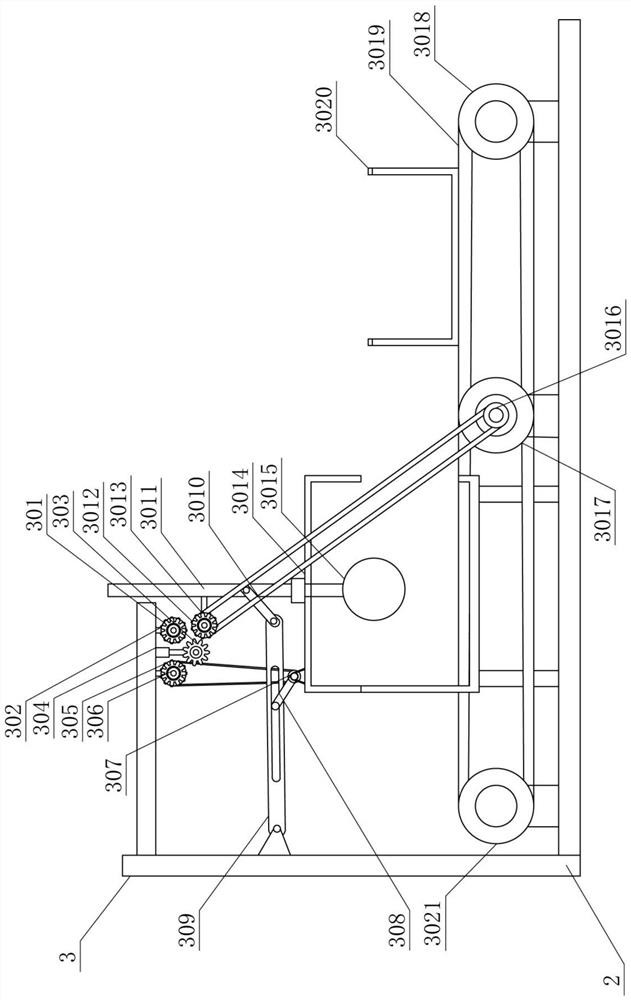

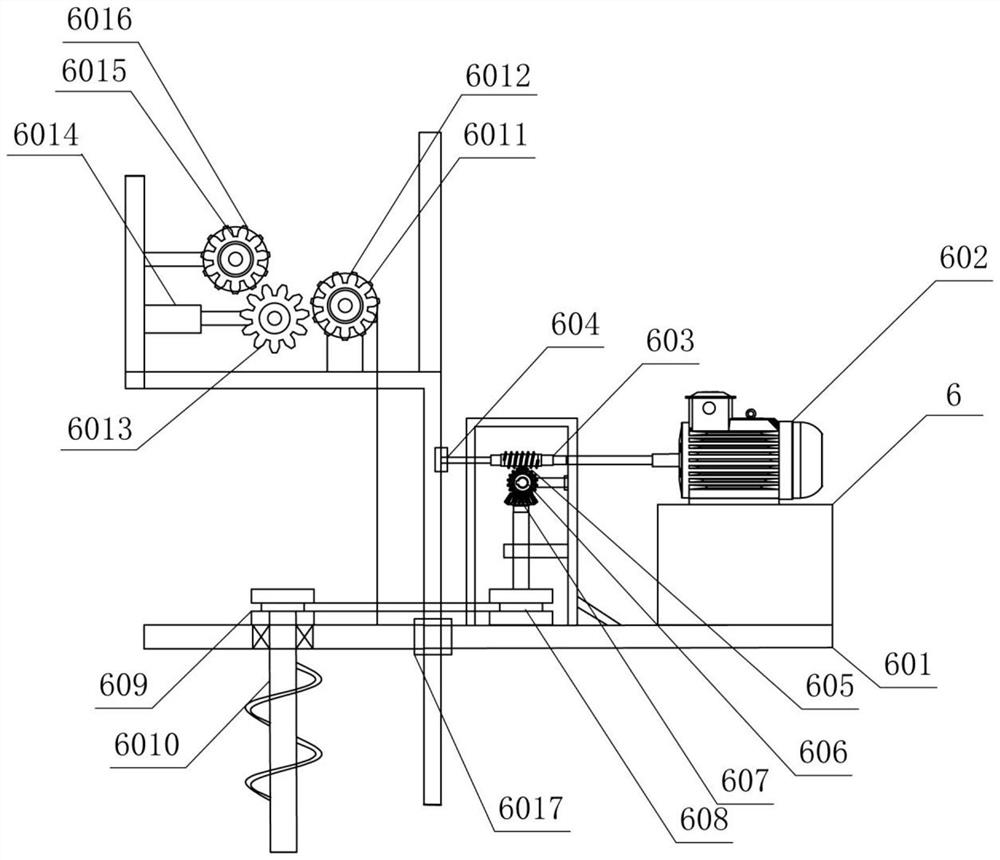

[0024] A clay smelting device for making ceramics, such as Figure 1-6 As shown, it includes a base 1, a support frame 2, a conveying mud refining mechanism 3, a control panel 4, a spring telescopic rod 5, an elevating stirring mechanism 6, a shaking and impurity removal mechanism 7, and a feeding mechanism 8; the top of the base 1 and the support frame 2 for welding; the middle part of the top of the support frame 2 is provided with a transmission type mud refining mechanism 3; the middle part of the left side of the support frame 2 is provided with a control panel 4; The top of the side is provided with a rocking impurity removal mechanism 7; the top of the spring telescopic rod 5 is welded with the lifting type stirring mechanism 6, and the middle part of the left side of the lifting type stirring mechanism 6 is connected with the shaking impurity removal mechanism 7; There are feeding mechanism 8.

[0025] Wherein, the transfer type mud refining mechanism 3 includes a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com