Method and device for grasping and moving low-density magnet blanks formed by pressing

A press-forming, low-density technology, used in transportation and packaging, conveyor objects, etc., can solve problems such as easy breakage and low density of magnet blanks, and achieve the effect of ensuring quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

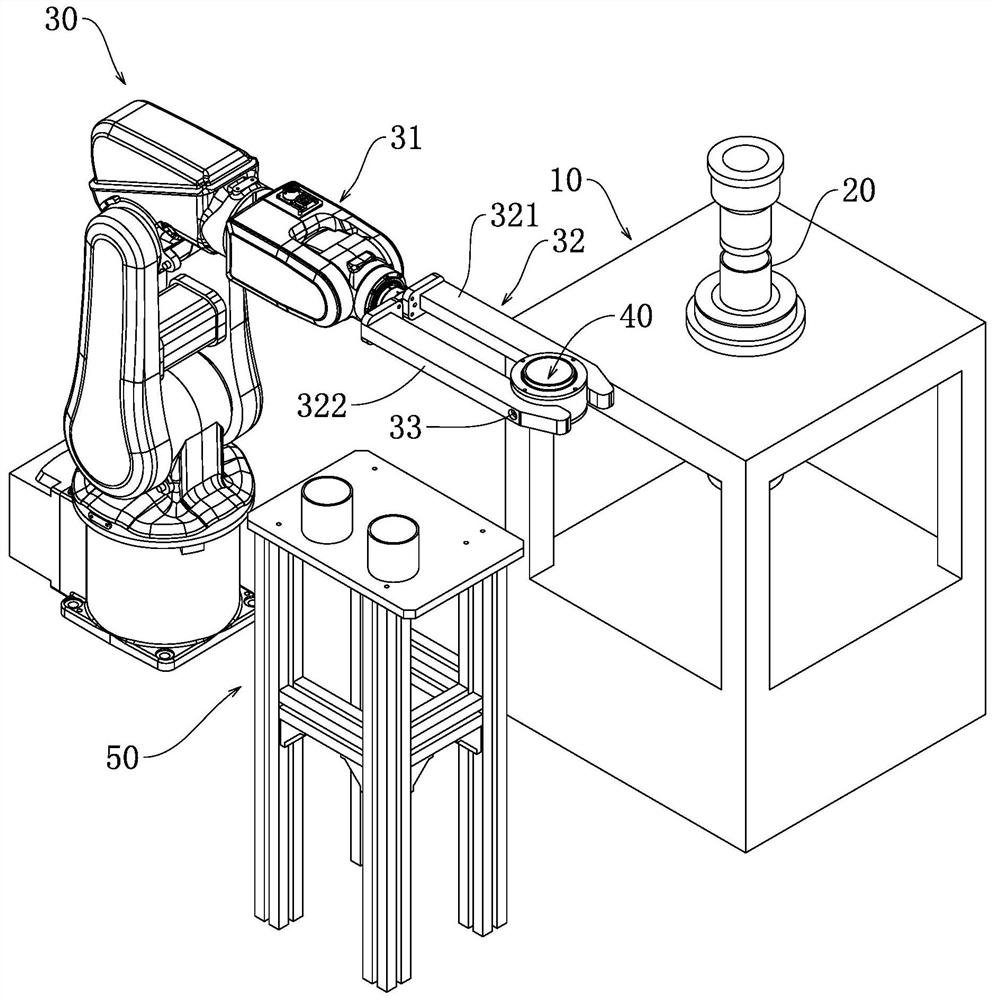

[0022] refer to figure 1 , the gripping and moving method of the low-density magnet blank of press molding of the present invention comprises the following steps:

[0023] S10: Low-density magnet blank pressing

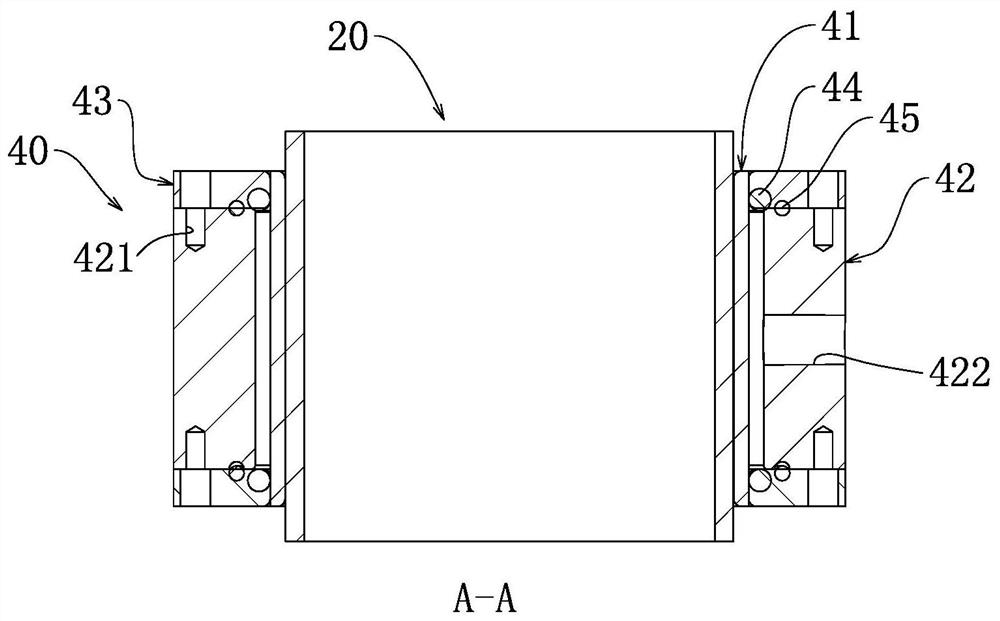

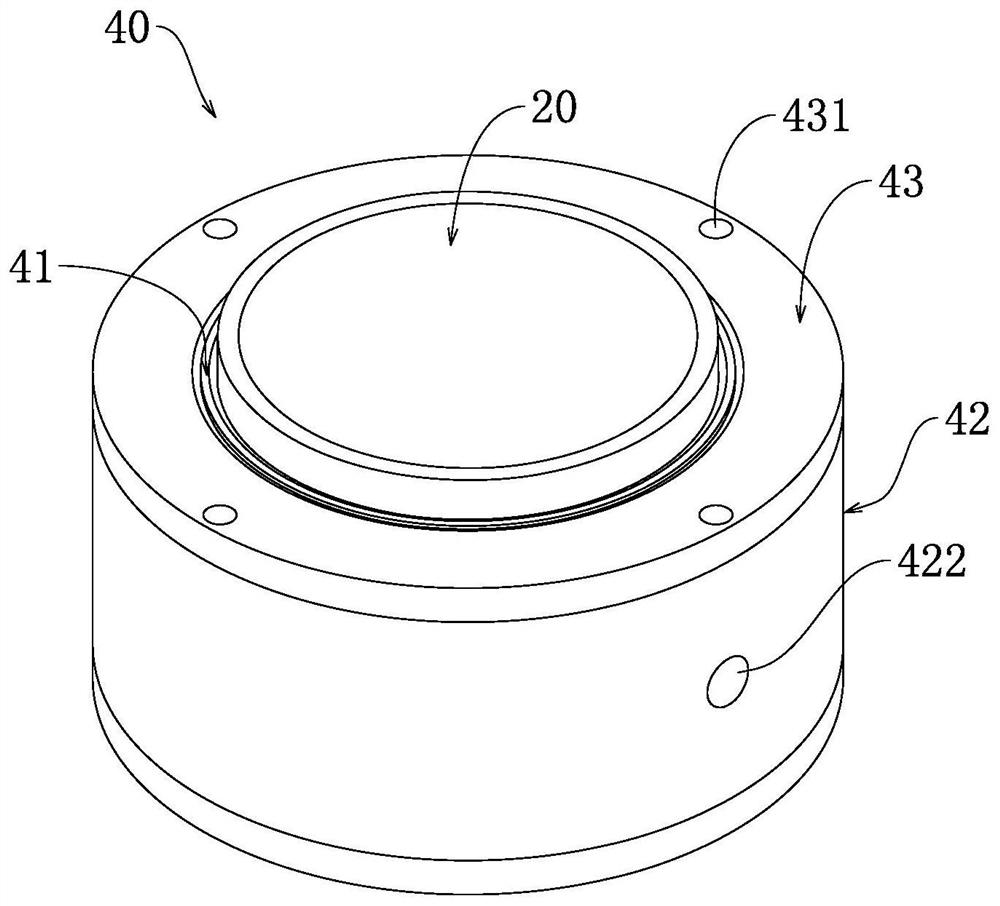

[0024] like figure 1 As shown, a low-density magnet blank 20 is molded by a press 10. In this step, the press 10 may be an applicable known magnet pressing equipment, which presses a magnet device such as a magnetic ring through a mold. The low-density magnet is loose and brittle, and can be easily reduced to magnetic powder in the subsequent magnetic field orientation compression molding, which has the same weight and size as the magnetic field orientation compression molding magnet. In this embodiment, the press 10 molds a low-density magnet blank 20 under relatively small pressure. After pressing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com