Sulfur recovery device washing water recycling system and sulfur recovery device washing water recycling method

A technology for sulfur recovery and washing water, applied in the field of coal chemical industry, can solve the problems of high methanol content, high energy consumption, large pollution, etc., and achieve the effects of increasing the amount of washing water, improving the recovery efficiency, and stabilizing the operation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

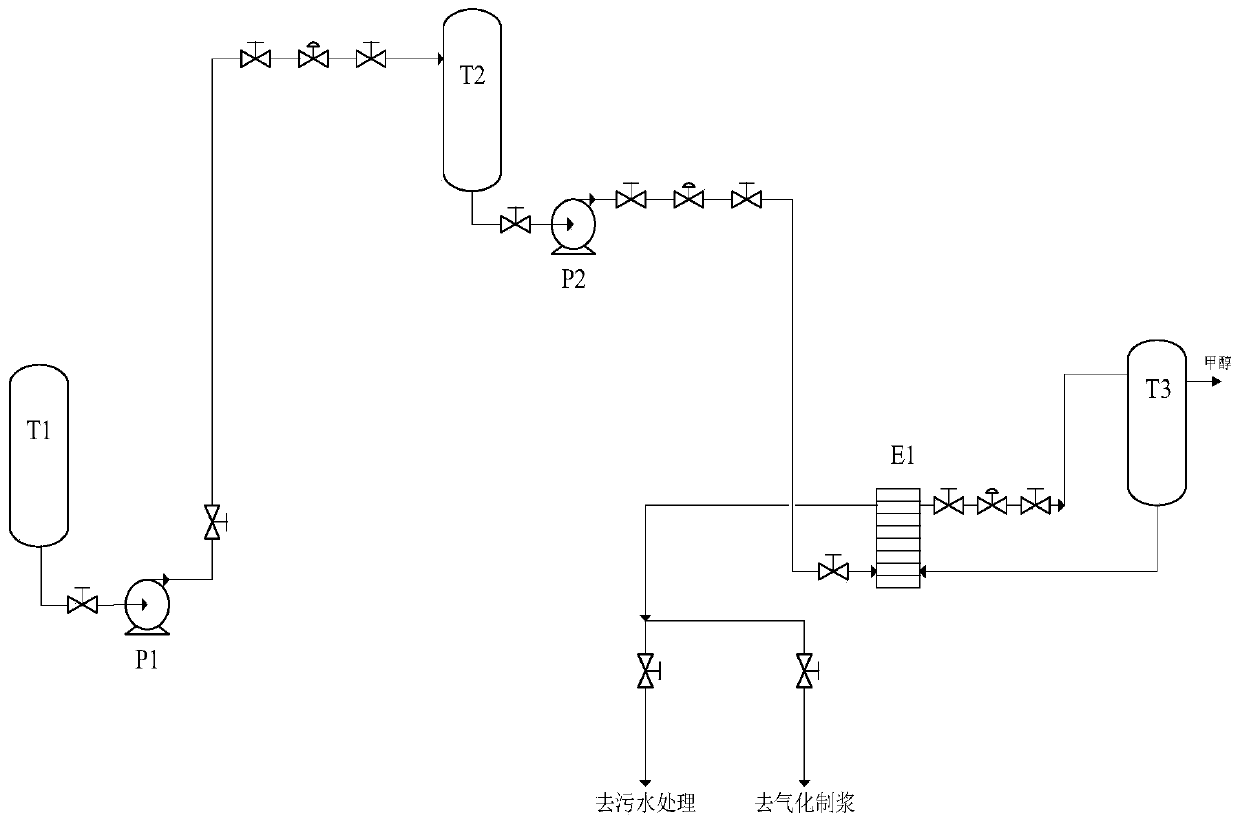

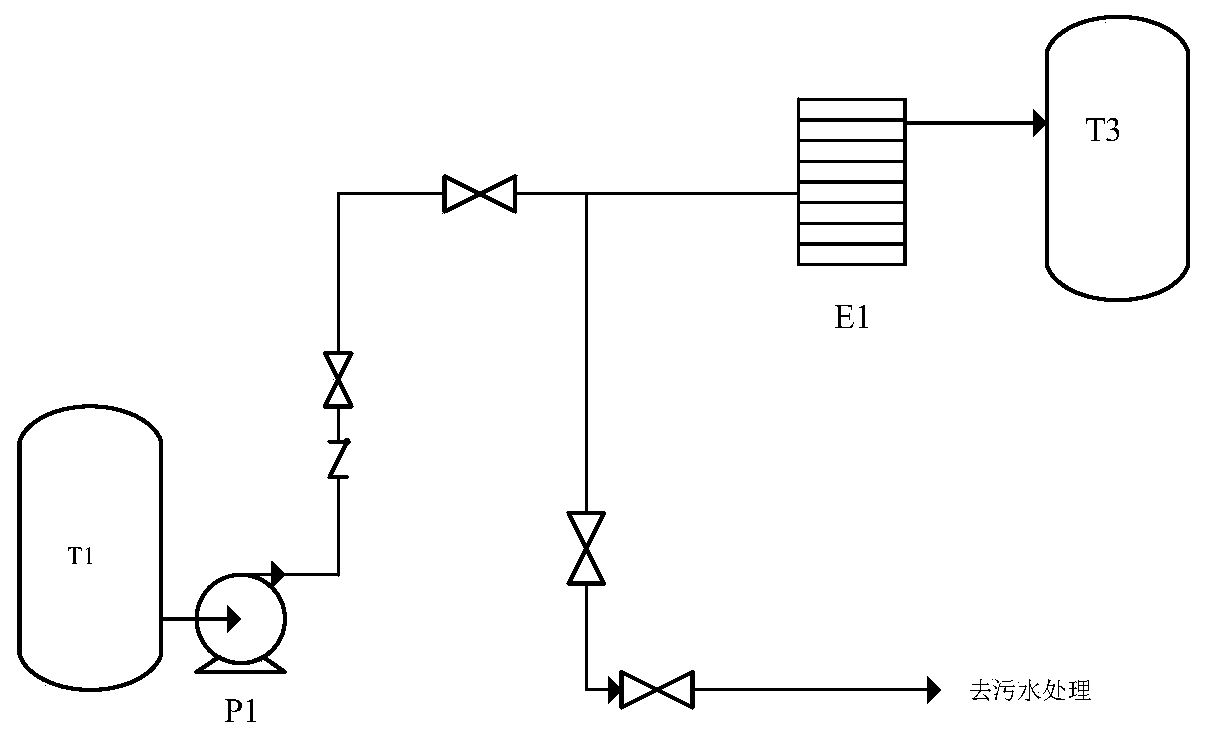

[0077] Such as figure 1 As shown, the washing water recovery and reuse system of the sulfur recovery unit includes a methanol scrubber tail gas scrubber T1, an acid gas scrubber T2, a methanol-water separation tower T3, a first transfer pump P1, a second transfer pump P2 and a heat exchange system E1;

[0078] The methanol tail gas scrubber T1 is communicated with the acid scrubber T2 through the first transfer pump P1 through a pipeline;

[0079] The acid washing tower T2 is connected with the methanol-water separation tower T3 via the second transfer pump P2 through a pipeline.

[0080] The heat exchange system E1 is in communication with the second transfer pump P2 and the methanol-water separation tower T3 respectively through pipelines.

[0081] Further, the desalted water from the bottom of the methanol scrubbing tail gas scrubber T1 is transferred to the top of the acid gas scrubber T2 through the transmission of the first transfer pump P1, and is reversely contacted w...

Embodiment 1

[0086] Such as figure 1 As shown, the washing water recovery and reuse system of the sulfur recovery unit includes a methanol scrubber tail gas scrubber T1, an acid gas scrubber T2, a methanol-water separation tower T3, a first transfer pump P1, a second transfer pump P2 and a heat exchange system E1;

[0087] The methanol tail gas scrubber T1 is communicated with the acid scrubber T2 through the first transfer pump P1 through a pipeline;

[0088] The acid washing tower T2 is connected with the methanol-water separation tower T3 via the second transfer pump P2 through a pipeline.

[0089] The heat exchange system E1 is in communication with the second transfer pump P2 and the methanol-water separation tower T3 respectively through pipelines.

[0090] Further, the desalted water with a methanol content of 0.5wt% from the bottom of the methanol scrubber T1 is transferred to the top of the acid gas scrubber T2 through the transmission of the first transfer pump P1, and the acidi...

Embodiment 2

[0094] Such as figure 1 As shown, the washing water recovery and reuse system of the sulfur recovery unit includes a methanol scrubber tail gas scrubber T1, an acid gas scrubber T2, a methanol-water separation tower T3, a first transfer pump P1, a second transfer pump P2 and a heat exchange system E1;

[0095] The methanol tail gas scrubber T1 is communicated with the acid scrubber T2 through the first transfer pump P1 through a pipeline;

[0096] The acid washing tower T2 is connected with the methanol-water separation tower T3 via the second transfer pump P2 through a pipeline.

[0097] The heat exchange system E1 is in communication with the second transfer pump P2 and the methanol-water separation tower T3 respectively through pipelines.

[0098] Further, the desalted water with a methanol content of 0.1wt% from the bottom of the methanol scrubber T1 is transferred to the top of the acid gas scrubber T2 through the transmission of the first transfer pump P1, and the acidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com