Heat-insulation laminated glass for automobiles and preparation method of glass

A technology of laminated glass and manufacturing method, applied to windshields, vehicle parts, windows, etc., can solve problems such as interlayer ripples or pits, and achieve the effect of ensuring appearance quality and eliminating appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further described below in conjunction with the accompanying drawings.

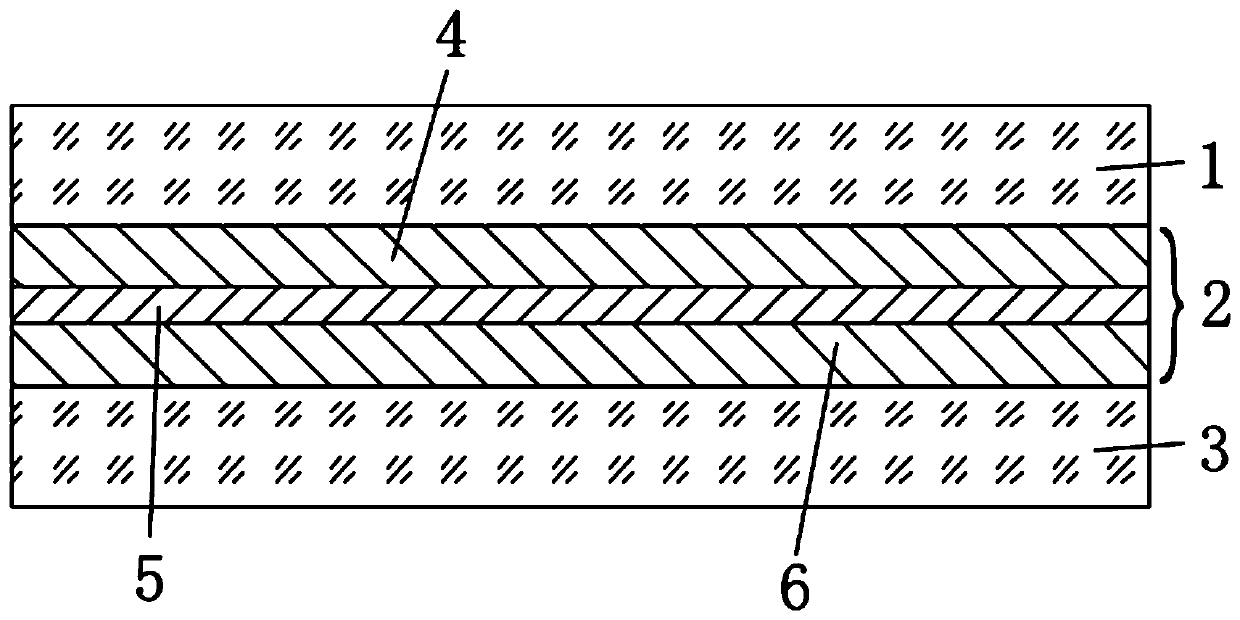

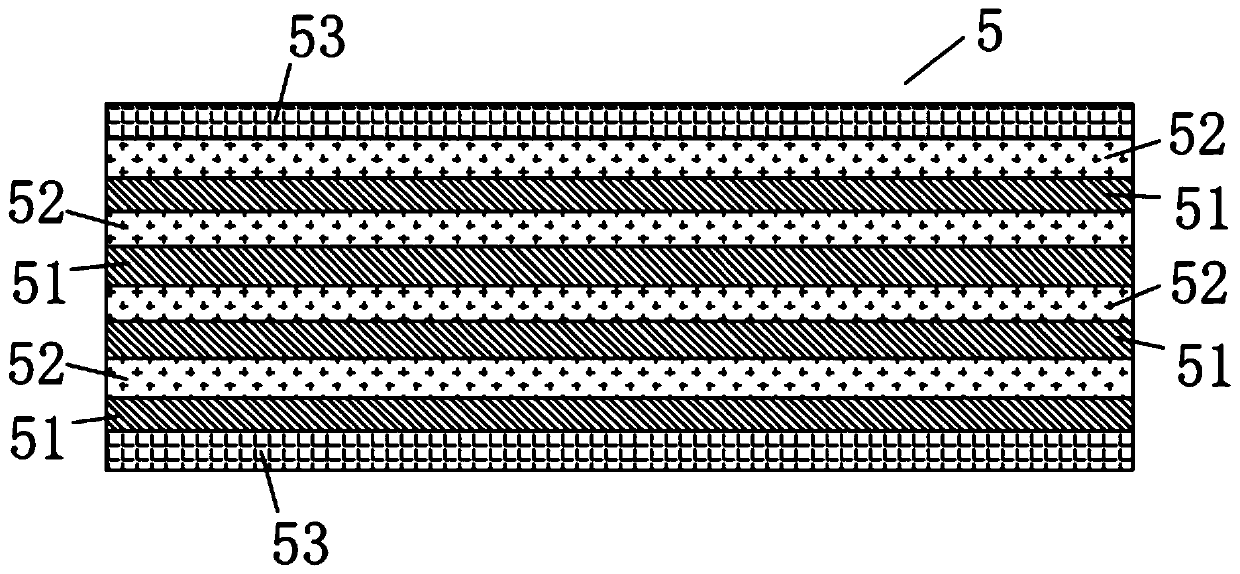

[0026] Such as figure 1 with figure 2 As shown, a heat-insulating automotive laminated glass according to the present invention includes an outer glass plate 1, a heat-insulating interlayer 2 and an inner glass plate 3, and the heat-insulating interlayer 2 is sandwiched between the outer glass plate 1 and the inner glass Between the boards 3, the heat insulating intermediate layer 2 includes a first thermoplastic resin film 4, an infrared reflective film 5 and a second thermoplastic resin film 6 stacked in sequence, and the infrared reflective film 5 includes at least two resin layers stacked together Films 51, 52, the difference between the refractive index of two adjacent resin films 51, 52 is greater than or equal to 0.05, preferably the difference between the refractive index of two adjacent resin films 51, 52 is greater than or equal to 0.1, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com