System and process for recycling second-acid tower kettle liquid waste heat

A diacid tower, waste heat recovery technology, applied in the separation/purification of carboxylic acid compounds, the preparation of carboxylate salts, the preparation of organic compounds, etc. , the problem of low purity of formic acid in the tri-acid tower, etc., to achieve the effect of universality, low cost, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

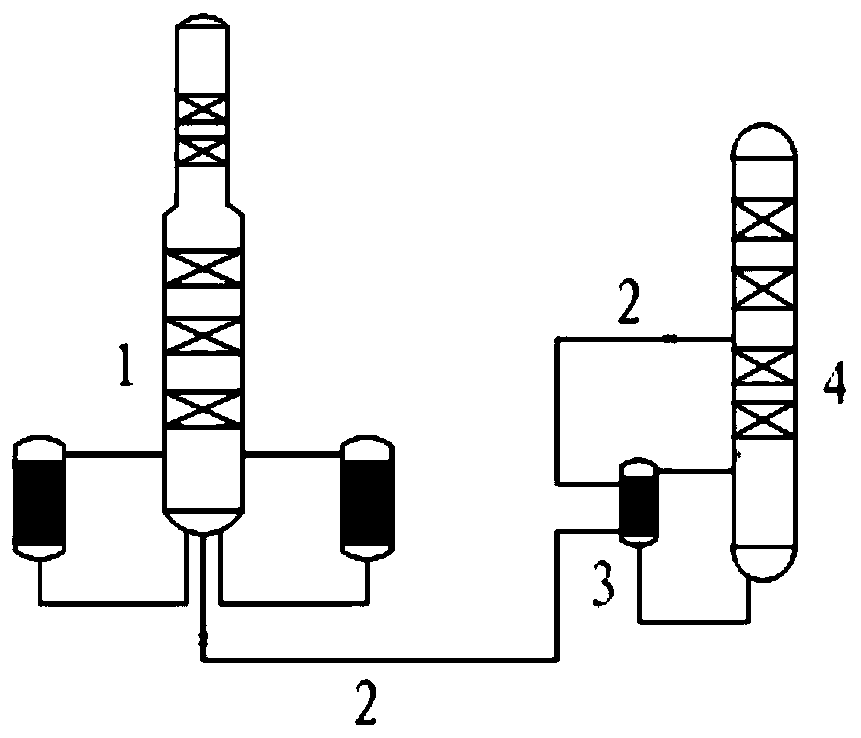

[0043] Such as figure 1 As shown, a process for recovery and utilization of waste heat from the bottom liquid of the two-acid tower, including the bottom liquid (154°C) of the two-acid tower 1 enters the reboiler B3 of the three-acid tower through the transfer line 2, and the bottom liquid of the three-acid tower is treated Raise the temperature, then the liquid in the bottom of the second tower (98° C.) returns to the transfer line 2, and then enters the middle part of the three-acid tower 4. Utilize the residual heat of the diacid tower bottom liquid.

[0044] The results of one-year production operation show that the average purity of triacid tower formic acid is 87%.

Embodiment 2

[0046] A system for recovering waste heat from the bottom liquid of a diacid tower, comprising: a diacid tower 1, a three acid tower 4, a reboiler B3, the liquid outlet of the bottom of the diacid tower 1 and the reboiler of the three acid tower The shell-side liquid inlet of B3 is connected, and the liquid discharge port of the three-acid tower reboiler B3 is connected with the liquid inlet in the middle of the three-acid tower 4 .

[0047] Aiming at the problem that the current diacid tower 1 uses a large amount of circulating water and is easy to scale. In the present invention, the liquid in the 1st tower of the di-acid tower is connected to the lower side of the shell side of the reboiler B3 of the three-acid tower through the pipeline 2, and it is used as a heat source to heat up the 4th tower of the three-acid tower, so that the heat of the liquid in the 1st tower of the di-acid tower Effective conduction to the three-acid tower 4 not only reduces the consumption of cir...

Embodiment 3

[0050] A system for recovering waste heat from the bottom liquid of a diacid tower, comprising: a diacid tower 1, a three acid tower 4, a reboiler B3, the liquid outlet of the bottom of the diacid tower 1 and the reboiler of the three acid tower The shell-side liquid inlet of B3 is connected, and the liquid discharge port of the three-acid tower reboiler B3 is connected with the liquid inlet in the middle of the three-acid tower 4 .

[0051] Described diacid tower 1 is also provided with a plurality of heat exchangers, the tower bottom liquid of diacid tower is heated (reboiler) or cooling (still liquid cooler), as figure 1 The heat exchangers on the left and right sides of the intermediate diacid tower 1 meet the different requirements for the use of the still liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com