Solidification experience method for defining splashing in converter blowing period

A converter blowing and empirical method technology, which is applied in the manufacture of converters, etc., can solve problems such as the inability of secondary dust removal facilities to effectively recover, high concentration of overflowing flue gas, and severe carbon-oxygen reactions, etc., with high accuracy, simple method, and Good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following specific examples illustrate the present invention in further detail.

[0026] An empirical method of solidification for defining the occurrence of slopping during converter blowing, comprising the following steps:

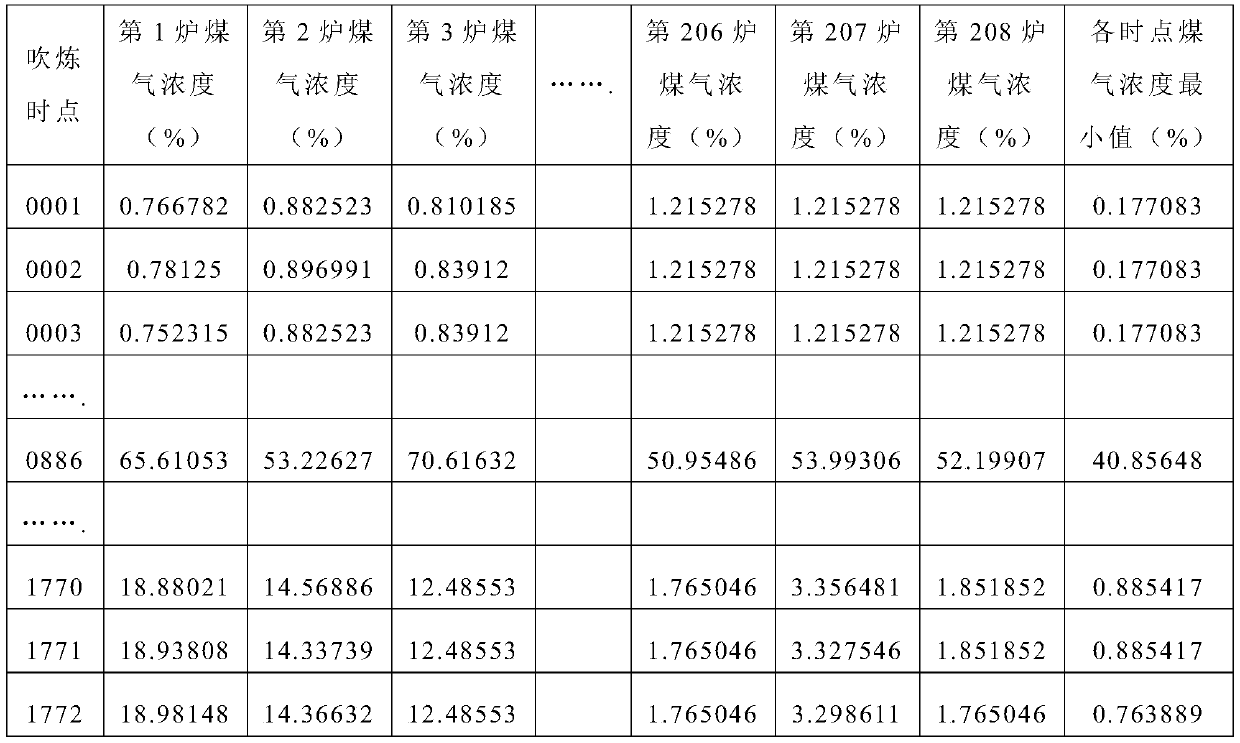

[0027] A) Collect 1000 furnace converter blowing data, screen out 208 converter converter blowing records without splashing, and take the minimum value of gas concentration at each time point according to the blowing time point, as shown in the following table:

[0028]

[0029] formed as figure 1 The gas concentration minimum curve under normal blowing conditions is shown;

[0030] B) In the actual steelmaking process, the gas concentration data in the converter is obtained in real time to form a real-time change curve of gas concentration, and the gas concentration minimum value curve under normal blowing conditions obtained in step A) is compared according to the blowing time point ;

[0031] C) When the real-time change curve of gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com