Method for cleaning engine

An engine and cleaning technology, applied to engine components, machines/engines, organic cleaning compositions, etc., can solve the problems of troublesome disassembly and cleaning, long cleaning time, environmental or human impact, etc., to avoid corrosion and environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

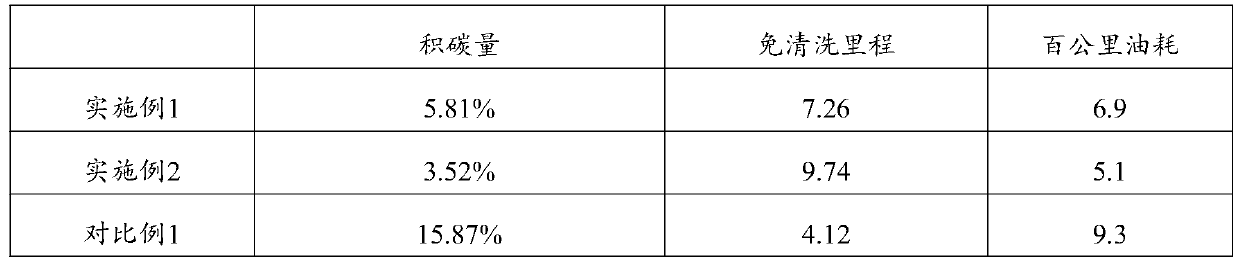

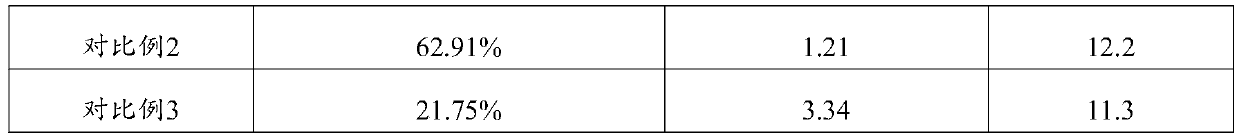

Examples

Embodiment 1

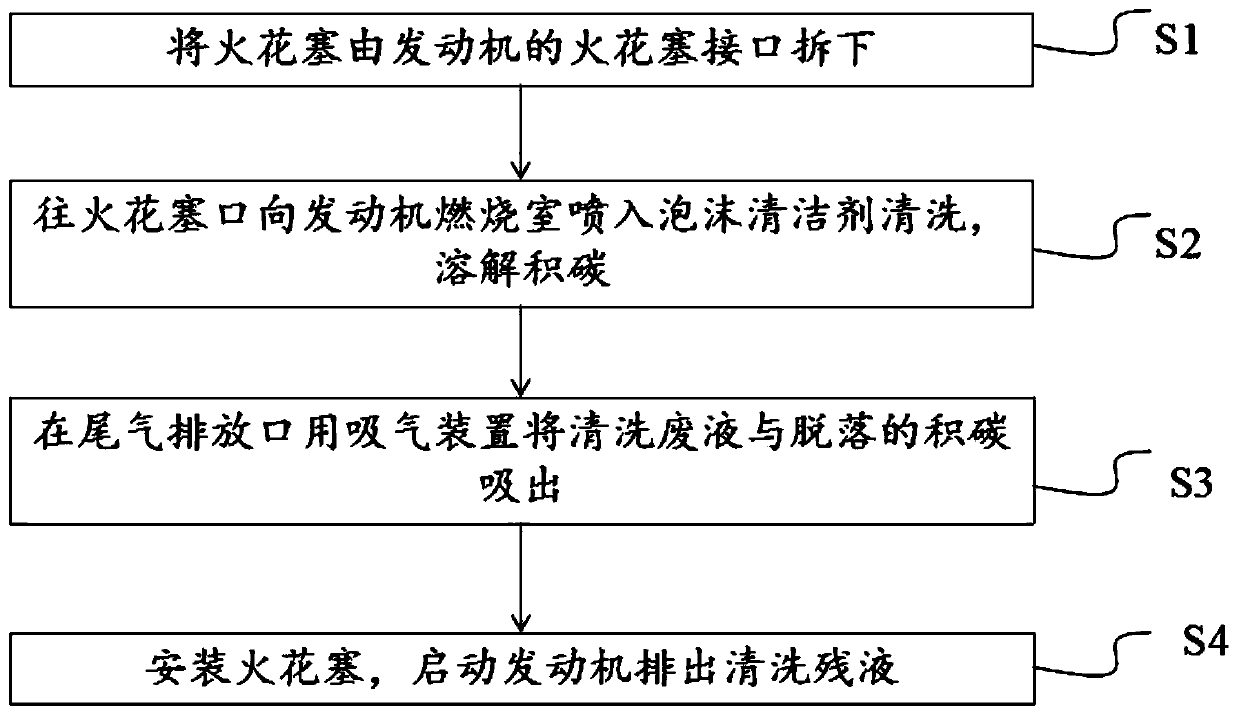

[0031] A cleaning method for an engine, comprising the steps of:

[0032] S1: Remove the spark plug from the spark plug interface of the engine;

[0033] S2: Spray foam cleaner into the engine combustion chamber at the spark plug port to clean and dissolve carbon deposits;

[0034] S3: Use the suction device at the exhaust outlet to suck out the cleaning waste liquid and the fallen carbon deposit;

[0035] Specifically in step S3,

[0036] S31: Spray the mixture of non-oily detergent and water into the spark plug port for cleaning;

[0037] S32: Use an air suction device at the exhaust outlet to suck out the waste liquid and the fallen carbon deposit after cleaning in step S31;

[0038] S33: Drying the detached carbon deposits remaining in the combustion chamber with an air gun.

[0039] S4: Install the spark plug, start the engine and discharge the cleaning residue.

[0040] In this embodiment, the spark plug of the engine is removed, and then the foam cleaning agent is ...

Embodiment 2

[0051] Different from Embodiment 1, the following steps are also included before step S1:

[0052] S01: Add non-oily detergent to the engine inlet to clean the lubrication system;

[0053] S02: Start the engine at idle speed;

[0054] S03: Turn off the engine.

[0055] After the above steps, clean the engine lubrication system with a non-oily detergent. Specifically, in step S02, start the engine to run at idle speed for about 30 to 45 minutes. Non-oily cleaners can fully contact the inner wall of the lubrication system and have enough time to react with carbon deposits.

[0056] In this embodiment, after step S03, enter the cleaning step of embodiment 1, namely

[0057] S1: Remove the spark plug from the spark plug interface of the engine;

[0058] S2: Spray foam cleaner into the engine combustion chamber at the spark plug port to clean and dissolve carbon deposits;

[0059] S3: Use the suction device at the exhaust outlet to suck out the cleaning waste liquid and the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com