Flat-plate-type heat collecting system and method

A flat-plate, heat-collecting technology, applied in solar heating systems, solar collectors, solar collector controllers, etc., can solve the problems of low light-to-heat conversion efficiency of heat-collecting systems, and achieve improved light-to-heat conversion efficiency, Increase heat absorption capacity and work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

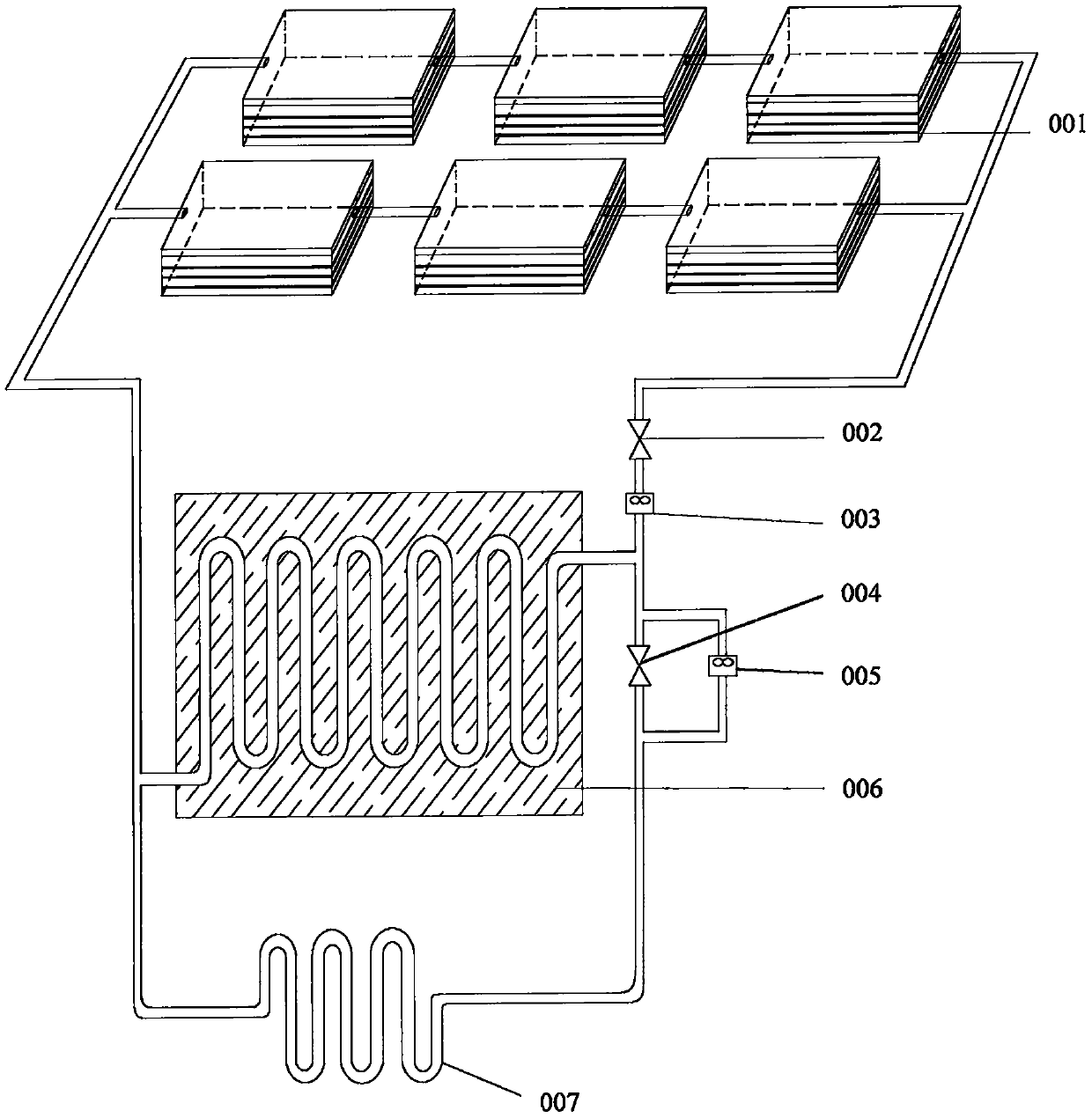

[0057] This embodiment provides a flat heat collecting system, such as figure 1 As shown, it includes: a flat plate heat collector 001, a first valve 002, a first fan 003, a second valve 004, a second fan 005, a heat storage device 006 and a heat exporter 007. The flat plate collectors 001 are connected in series and / or in parallel, such as figure 1 As shown, two sets of three flat-plate heat collectors 001 are connected in series respectively, and the two sets of flat-plate heat collectors 001 connected in series are then connected in parallel with each other. The total inlet connected in series and / or in parallel is connected to the outlet of the heat storage device 006 through a pipeline, and the total outlet is connected to the inlet of the heat storage device 006 through a pipeline through the first valve 002 and the first fan 003 in turn. The inlet of the heat exporter 007 is connected to the outlet of the heat storage device 006 through a pipeline, the outlet is connec...

Embodiment 2

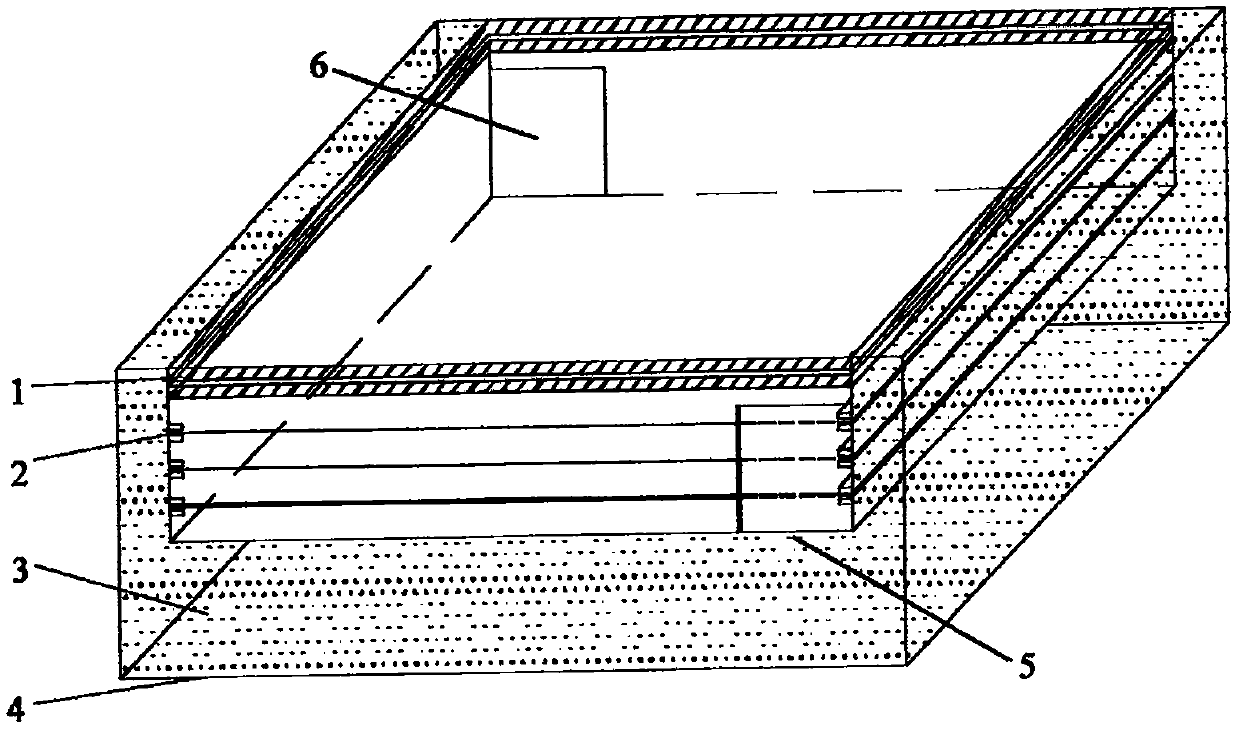

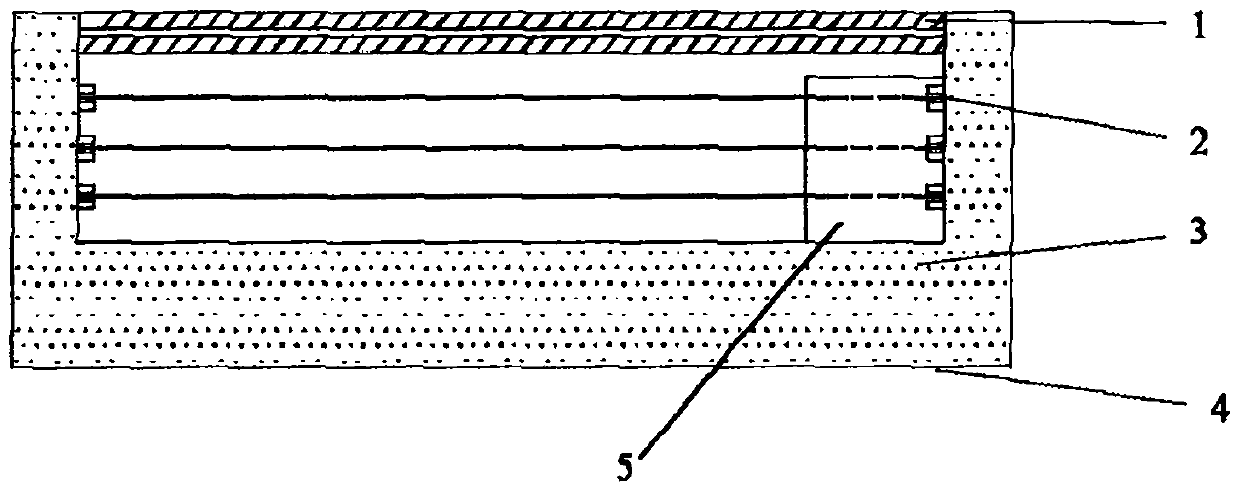

[0065] This embodiment provides a flat-plate heat collection system. The difference from Embodiment 1 is that the flat-plate heat collector in the flat-plate heat collection system includes: a glass plate 1, a metal mesh member 2, an insulation layer 3, and an outer shell 4 , the first vent 5 and the second vent 6. The glass plate 1 covers the upper part of the cavity surrounded by the shell 4 and is sealed with the shell 4 . The laminated array of at least two metal mesh members 2 is connected inside the cavity, which has adjustable heat storage and limited convection. The insulation layer 3 is connected to the inner wall of the shell 4 . The first vent 5 is opened on the first side wall of the shell 4, the second vent 6 is opened on the second side wall of the shell 4 opposite to the first side wall, the first vent 5 and the second vent 6 Non-coaxial phase-staggered settings.

[0066] The difference from Embodiment 1 is that at least two metal mesh members 2 have adjustab...

Embodiment 3

[0071] This embodiment provides a flat-plate heat collection system. The difference from Embodiment 1 is that the flat-plate heat collector in the flat-plate heat collection system includes: a glass plate 1, a metal mesh member 2, an insulation layer 3, and an outer shell 4 , the first vent 5 and the second vent 6. The glass plate 1 covers the upper part of the cavity surrounded by the shell 4 and is sealed with the shell 4 . The laminated array of at least two metal mesh members 2 is connected inside the cavity, which has adjustable heat storage and limited convection. The insulation layer 3 is connected to the inner wall of the shell 4 . The first vent 5 is opened on the first side wall of the shell 4, the second vent 6 is opened on the second side wall of the shell 4 opposite to the first side wall, the first vent 5 and the second vent 6 Non-coaxial phase-staggered settings.

[0072] The difference from Embodiment 1 is that at least two metal mesh members 2 have adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com